Why is an annealed piece easier to cut? Comprehensive analysis of the reasons

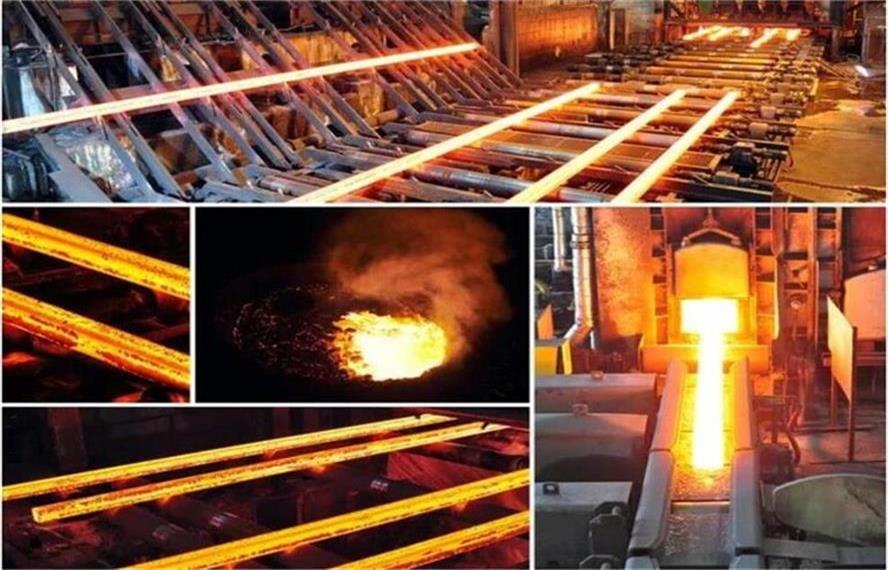

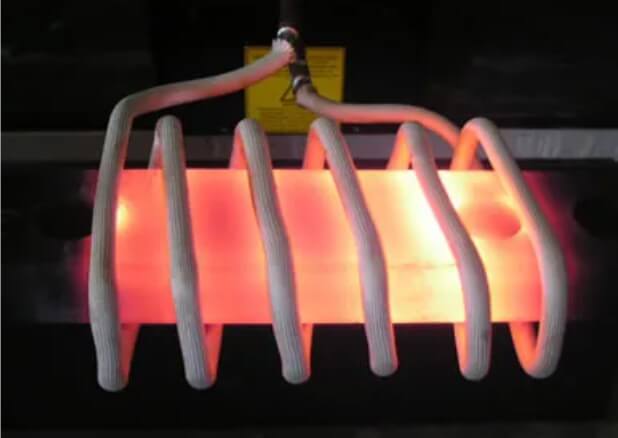

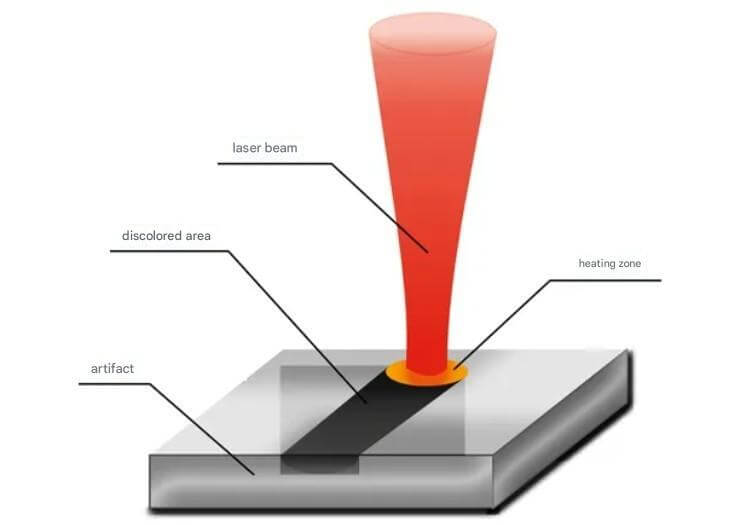

Annealing is a metal heat treatment process that changes the metal’s microstructure by heating it to a certain temperature and holding it for a period of time, then slowly cooling it to improve the metal’s mechanical properties.

So why is an annealed piece easier to cut? Will annealed metal parts show better machinability? This article will analyze in detail the reasons and effects of annealed parts being easier to cut from multiple perspectives.

1.Why is an annealed piece easier to cut——microstructure changes

(1) Eliminating internal stress:

Metals will produce internal stress during casting, forging or other processing. The presence of internal stress will put the internal structure of the metal in an unstable high-energy state, resulting in cracks, deformation and other problems during cutting.

During the annealing process, the metal is heated above the recrystallization temperature, the atomic activity is enhanced, and it can be rearranged and combined to eliminate internal stress, making the internal structure of the metal more stable. Therefore, the annealed metal is less likely to crack and deform during cutting, and the cutting process is smoother. Why is an annealed piece easier to cut? This is one of the important reasons.

(2) Grain refinement:

Unannealed metals may have a coarse grain structure. Coarse grains will cause the tool to bear greater cutting force during cutting, and it is easy to produce cutting nodules, affecting the cutting quality.

Why is an annealed piece easier to cut? This is because during the annealing process, the metal undergoes recrystallization, and the coarse grains are refined into fine equiaxed grains. The refined grain structure can evenly distribute stress, reduce cutting force and cutting heat during cutting, thereby improving cutting efficiency and surface quality.

(3) Reduce hardness:

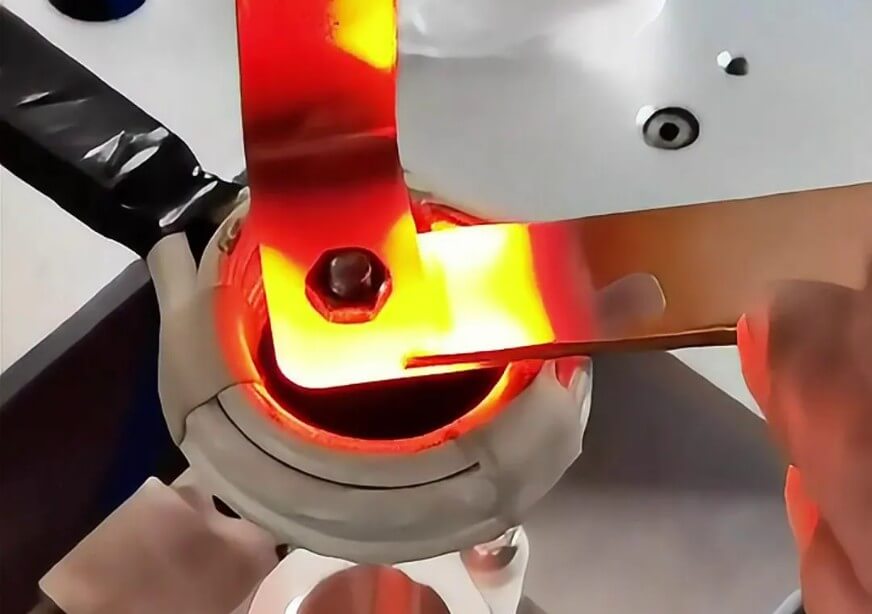

Metals with high hardness require greater cutting force and higher cutting temperature during cutting, which can easily cause tool wear and breakage. During the annealing process, carbides and other strengthening phases in the metal will dissolve or spheroidize, reducing the hardness of the metal.

When cutting metals with reduced hardness, the cutting force on the tool is reduced, the cutting temperature is reduced, the tool life is extended, and the cutting process is easier.

2.Why is an annealed piece easier to cut——Mechanical properties change

(1) Improve plasticity:

Plasticity refers to the ability of metal materials to deform plastically without breaking when subjected to external forces. Unannealed metals have low plasticity and are prone to brittle fracture when cut.

After annealing, the plasticity of the metal is significantly improved, which can better adapt to the cutting force during the cutting process, reduce the occurrence of brittle fracture, and improve the cutting quality.

(2) Reduce brittleness:

Brittleness refers to the property of metal materials that are prone to fracture when subjected to external forces. Highly brittle metals are prone to edge collapse and slag during cutting, which affects cutting accuracy and surface quality.

Why is an annealed piece easier to cut? This is because annealing can reduce the brittleness of metals, making them more stable during cutting and reducing the occurrence of edge collapse and slag.

(3) Improve toughness:

Toughness refers to the ability of metal materials to absorb energy without breaking when subjected to dynamic loads such as impact or vibration. Unannealed metals have poor toughness and are prone to cracks and fractures when cut.

After annealing, the toughness of the metal is improved, and it can better resist impact and vibration during the cutting process, reduce the occurrence of cracks and fractures, and improve the safety and reliability of cutting.

3.Why is an annealed piece easier to cut——the influence of cutting force

(1) Reduce cutting force:

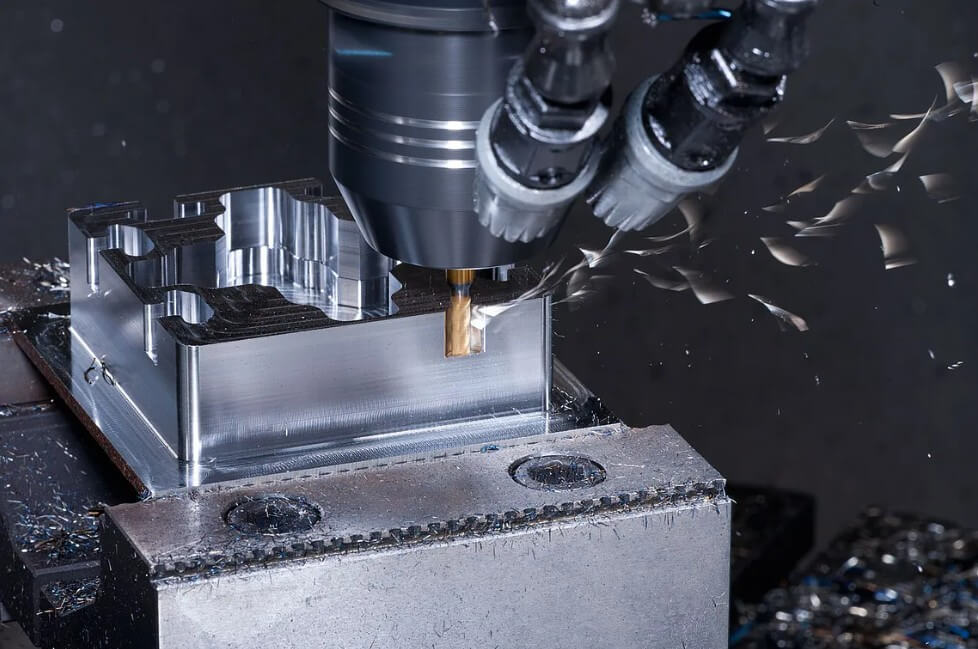

The cutting force is the force required by the tool to overcome metal deformation and fracture during the cutting process. Unannealed metal has high hardness and high brittleness, and requires a large cutting force when cutting.

After annealing, the hardness of the metal decreases and the plasticity increases, the cutting force required for cutting is reduced, the wear and breakage of the tool is reduced, and the cutting process is easier. Why is an annealed piece easier to cut? The reduction of cutting force is one of the important factors.

(2) Reduce cutting temperature:

The cutting temperature is the phenomenon of temperature rise caused by the heat generated by friction and plastic deformation during the cutting process. High cutting temperature will lead to increased tool wear and reduced cutting quality.

After annealing, the cutting force of the metal is reduced, the cutting temperature is reduced, the service life of the tool is extended, and the cutting quality is improved.

(3) Reduce cutting vibration:

Cutting vibration is the vibration phenomenon caused by factors such as cutting force fluctuation and uneven internal structure of metal during cutting. Cutting vibration will lead to reduced cutting accuracy and poor surface quality.

The internal structure of the metal after annealing is more uniform, the cutting force is more stable during cutting, the cutting vibration is reduced, and the cutting accuracy and surface quality are improved.

4.Why is an annealed piece easier to cut——the influence of different annealing processes on cutting performance

(1) Complete annealing:

Complete annealing is mainly used for hypoeutectoid steel, which can significantly reduce the hardness of the material, improve plasticity, refine the grains, and improve the structure, making the material easier to cut. The cooling rate of complete annealing is slow, which can ensure that the supercooled austenite completely transforms into pearlite and forms a uniform structure.

(2) Isothermal annealing:

Isothermal annealing is to heat the steel to a temperature higher than Ac3 (or Ac1), keep it for an appropriate time, and then quickly cool it to a certain temperature in the pearlite temperature range and keep it isothermally, so that the austenite transforms into a pearlite structure. Isothermal annealing can refine the grains, make the structure uniform, and reduce the hardness, thereby improving the cutting performance of the material.

(3) Spheroidizing annealing:

Spheroidizing annealing is mainly used for eutectoid steel and hypereutectoid steel, which can spheroidize the carbides in the steel to form spherical pearlite structure. This structure has low hardness and good plasticity, which is convenient for cutting. When the structure after spheroidizing annealing is quenched and heated, the austenite grains are not easy to grow, and the workpiece has little tendency to deform and crack during cooling.

(4) Stress relief annealing:

Stress relief annealing is an annealing process to eliminate the residual stress caused by plastic deformation processing, welding, etc. and the residual stress existing in the casting. Stress relief annealing can eliminate the residual stress inside the material, prevent the material from deforming and cracking during the cutting process, and improve the cutting accuracy and stability.

(5) Recrystallization annealing:

Recrystallization annealing is a heat treatment process in which the metal after cold deformation is heated to above the recrystallization temperature and maintained for an appropriate time to allow the deformed grains to recrystallize into uniform equiaxed grains to eliminate deformation strengthening and residual stress. Recrystallization annealing can refine the grains, improve the structure, reduce the hardness, and thus improve the cutting performance of the material.

5.Advantages of annealed parts in practical applications

(1) Improve production efficiency:

Since the annealed metal is easier to cut, the cutting force and cutting temperature required during the cutting process are reduced, the service life of the tool is extended, and the cutting efficiency is improved.

At the same time, the cutting vibration and cutting nodules generated by the annealed metal during the cutting process are reduced, the cutting accuracy and surface quality are improved, the workload of subsequent processing is reduced, and the production efficiency is further improved.

(2) Reduce production costs:

The annealed metal reduces tool wear and breakage during the cutting process, the service life of the tool is extended, and the consumption cost of the tool is reduced. At the same time, due to the improvement of cutting efficiency and the reduction of subsequent processing workload, the production cost is also reduced.

(3) Expand the scope of application:

Annealing process can be applied to various metal materials, including carbon steel, alloy steel, stainless steel, cast iron, etc. Through annealing treatment, the mechanical properties of these metal materials can be improved, making them easier to cut, and expanding the scope of application of metal materials.

6.Summary

In summary, the relevant content of “Why is an annealed piece easier to cut” is systematically analyzed. The reasons for its easy cutting mainly include changes in microstructure, changes in mechanical properties, the influence of cutting force, and its advantages in practical applications. These factors work together to make the annealed metal show better machinability during the cutting process, providing important technical support for the processing and application of metal materials.