Analysis of the advantages and applications of investment casting process

1.Introduction to investment casting process

Investment casting, also known as precision casting or lost wax casting, is a manufacturing process that uses a wax pattern to form a disposable ceramic mold. The wax pattern is formed into the shape of the object to be cast, coated with a refractory ceramic material, and heated to remove the wax after the ceramic solidifies to form a consumable ceramic mold. The molten metal is poured into it, cooled, and finally the metal casting is removed.

Investment casting is generally superior to other molding methods because the casting has fine details and excellent surface finish after casting. As one of the most complex casting processes, it can form complex shapes while maintaining high dimensional accuracy and high surface quality, and can be used to cast almost any metal that meets the requirements of various end-market applications.

2.Detailed explanation of investment casting process

(1) Tool design/assembly

Design and assemble molds to produce patterns identical to the finished product, laying the foundation for subsequent casting. Use advanced CAD and CAM technology to ensure precision mold manufacturing and achieve precise, high-quality final casting.

(2) Installing wax figures and making trees

Injecting semi-solid wax using an in-house automated process to improve the dimensional stability of the wax model. Set up the wax model to ensure precise positioning, create a tree structure to improve production efficiency, and connect multiple wax models to a central casting system.

(3) Making ceramic shells

The wax model is dipped into ceramic slurry, coated with sand ash and repeated, and dried to increase the thickness and strength of the ceramic shell. Strictly control the drying temperature and time to ensure consistent quality.

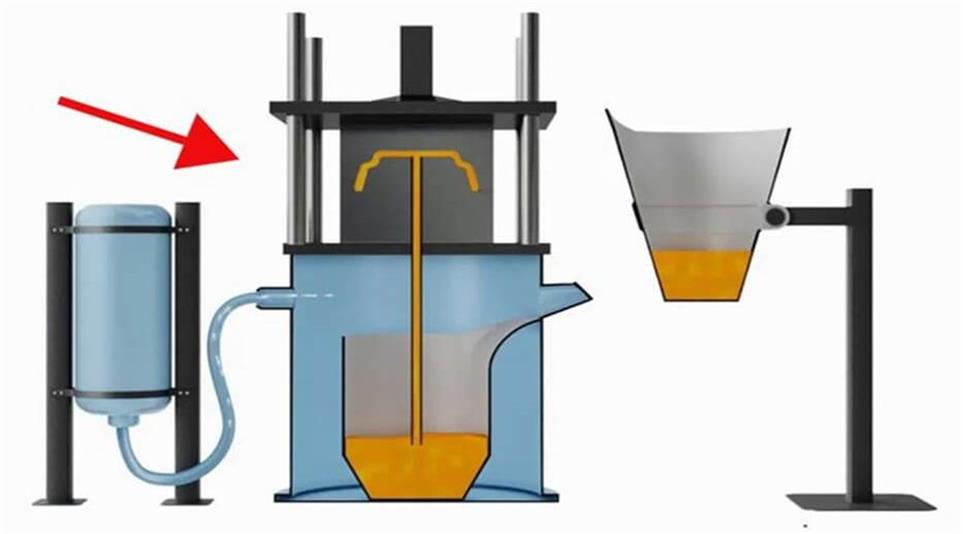

(4) Wax removal

Put the part in a steam autoclave and heat it to melt the wax, forming a cavity for the metal to be poured, ensuring that the wax is completely discharged.

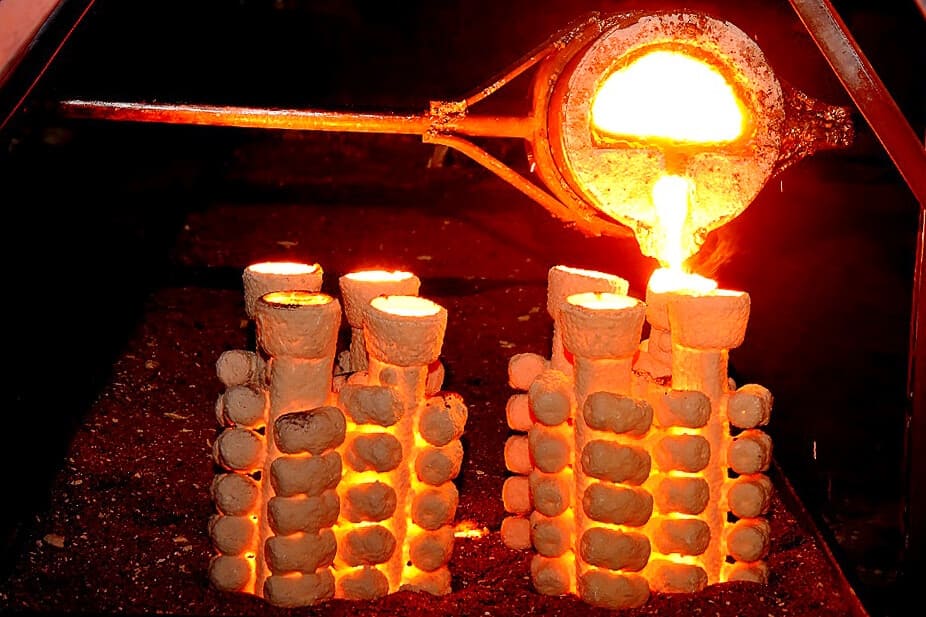

(5) Filling

Pour the molten metal into the ceramic shell cavity, and precisely control the temperature, flow rate and pouring pressure to avoid defects.

(6) Shell

Remove the casting by breaking the shell, being careful not to damage it.

(7) Finishing

Perform post-processing processes such as sandblasting, electroplating, painting, assembly, and machining according to quality requirements.

(8) Testing and Inspection

Strict testing and inspection of castings, including dimensional measurement, appearance inspection, mechanical property inspection, etc., to ensure that the quality meets the standards.

(9) Packaging and Transportation

According to the characteristics of the castings and transportation requirements, select appropriate packaging materials and methods to ensure that the castings are not damaged during transportation and arrive safely at the destination.

3.Advantages of Investment Casting

(1) Benefits of reducing defects and improving quality:

Products produced by investment casting are of excellent quality, with few defects, and the defect rate is much lower than that of sand casting. Strict post-control ensures that there are no defects.

(2) Advantages of flexible design:

Extremely high design freedom, with excellent adaptability to complex parts, especially parts with complex internal shapes. There is actually no restriction on the choice of materials, and it is also attractive for high-temperature alloys. It is not limited by the size, thickness and shape complexity of the castings, and the production method is flexible.

(3) Advantages of precise tolerance and clean shape:

It meets the good tolerance level of CT5-CT6, and can obtain pure or near-pure products, thereby reducing the labor cost of post-processing.

(4) Advantages of superior surface finish:

The surface quality of the finished product of investment casting is better than other casting processes, the tolerance control is more precise, and machining can be reduced or eliminated, providing superior surface finish, and complex text or LOGO can be cast, adding value to the product.

(5)Benefits of low waste and cost competitiveness:

The near-net shape reduces handling and minimizes material waste. The equipment cost is relatively low, the risk is low, the energy consumption, material consumption and mold cost are low, the initial investment in product development is small, and the production cost is competitive.

(6) Advantages of size customization and flexible quantity:

Castings of different sizes can be cast, and the quantity can be flexibly changed from small batches to large batches, with a low minimum order quantity, and the production cost of large and small batches is almost the same.

(7) Advantages of multiple materials:

In order to meet the needs of different application scenarios, a variety of alloy materials can be used, such as carbon steel, alloy steel, high-temperature alloy, stainless steel, etc.

5.Application of investment casting in daily life

Investment casting has a wide range of applications in life. Here are some specific examples:

(1) Automotive industry

1) Automotive decorative parts:

Some high-end automotive decorative parts such as car logos, hubcaps, etc. can also be produced by investment casting. These parts usually need to have high surface quality and complex shapes. Lost wax casting can provide excellent surface finish and precise dimensional control, making decorative parts more beautiful and durable.

2) Engine parts:

Some complex parts in automobile engines, such as turbocharger impellers, are manufactured by investment casting. The shape and size of these impellers must be precise to ensure performance and reliability at high speeds. Investment casting can meet these requirements and produce impellers with complex internal channels and thin surfaces, thereby improving engine efficiency and performance.

(2) Art field

1) Sculpture works:

Investment casting is also widely used in the field of artistic sculpture. Artists can use the investment casting process to transform designs into metal sculptures, achieving complex shapes and fine details. Investment casting can provide high-quality metal surfaces, making sculptures more vivid and artistic.

2) Jewelry Making:

Some high-end jewelry, such as necklaces, bracelets, rings, etc., can be made using the investment casting process. These jewelry usually need to have complex shapes and exquisite appearance. Investment casting can provide excellent surface quality and precise size control, making jewelry more beautiful and precious.

(3) Medical field

1) Dental restorations:

Crowns, bridges and other restorations in the dental field can be manufactured using lost wax casting. These restorations must perfectly match the shape of the patient’s mouth, have precise dimensions and good biocompatibility. Lost wax casting can make customized restorations based on the patient’s oral model, improving the restoration effect and patient comfort.

2) Medical equipment parts:

Some key components of medical equipment such as surgical instruments and implants can also be manufactured by investment casting. These parts must have high precision, high strength and good corrosion resistance. Investment casting can meet these requirements and ensure the performance and safety of medical equipment.

(4) Home field

1) Kitchenware accessories:

Some high-quality kitchenware accessories such as pot handles, pot lid buttons, etc. can also be produced by investment casting. These accessories must have high heat resistance, corrosion resistance and good mechanical properties. Lost wax casting can meet these requirements and improve the quality and service life of kitchen utensils.

2) Lighting accessories:

Some high-quality lighting accessories, such as chandelier lampshade brackets, table lamp bases, etc. can be produced by lost wax casting. These accessories usually have complex shapes and exquisite appearance. Investment casting can provide excellent surface quality and precise dimensional control, making the lamps more beautiful and durable.