What happens when you quench and temper iron?

Steel is the most widely used material in modern industry. Quenching and tempering are key links in the heat treatment process of steel. Many people are curious about what happens when you quench and temper iron.

This article will discuss the question of “what happens when you quench and temper iron”.And analyze the physical and chemical changes that occur in steel during quenching and tempering, and reveal the scientific principles behind them.

1.Quenching: The “rebirth of steel”

Quenching is a heat treatment process in which steel is heated to austenitizing temperature (generally 20℃~50℃ above Ac3 or Ac1), maintained for a certain period of time, and then cooled at a rate greater than the critical cooling rate. This process is like the “rebirth of steel”, giving it high hardness and wear resistance. The following will analyze in detail what happens when you quench and temper iron?

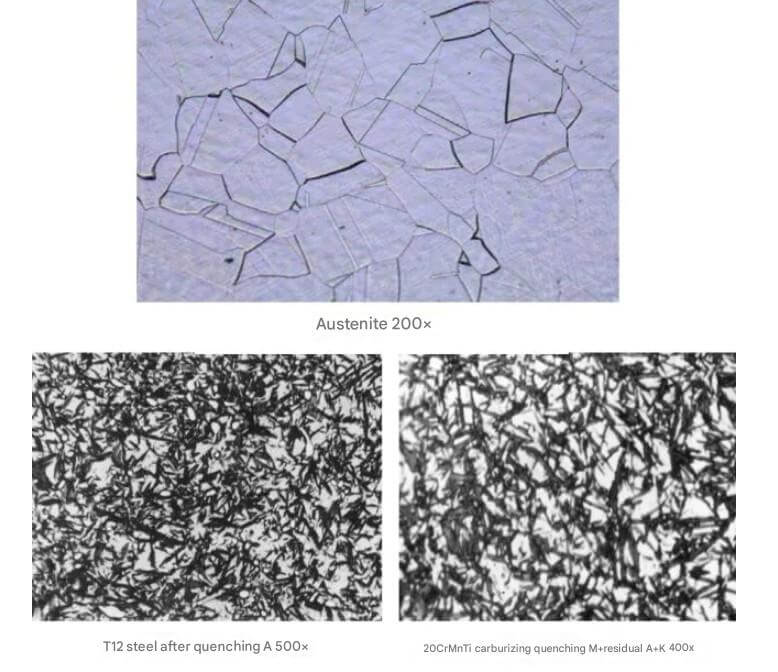

(1) What happens when you quench and temper iron: Austenitization

When steel is heated to above Ac3 or Ac1, the ferrite and cementite in the steel are completely transformed into austenite. This process prepares for subsequent quenching. The formation of austenite is the basis for quenching steel. Its uniform microstructure provides conditions for microstructure transformation during the subsequent cooling process.

Transformation diagram of austenite during quenching

(2) What happens when you quench and temper iron: rapid cooling

The key to quenching is rapid cooling. The cooling rate must be greater than the critical cooling rate to avoid pearlite or bainite transformation of austenite during cooling. Common quenching media include water, oil, salt bath, etc. Different media have different cooling capacities and have different effects on the microstructure and performance of steel.

For example, water has a stronger cooling capacity and is suitable for quenching carbon steel and low alloy steel; while oil has a weaker cooling capacity and is suitable for quenching high alloy steel and large workpieces to avoid excessive quenching stress causing deformation or cracking of the workpiece.

(3) What happens when you quench and temper iron: microstructure transformation

During the rapid cooling process, austenite transforms into martensite. Martensite is a hard and brittle structure with high hardness and high strength, but poor toughness. The formation of martensite is the key to obtaining high hardness and wear resistance in steel quenching.

(4) What happens when you quench and temper iron: performance changes

After quenching, the hardness and wear resistance of steel are significantly improved, but the toughness decreases and the internal stress increases. Therefore, the quenched steel needs to be tempered to adjust its mechanical properties and eliminate internal stress.

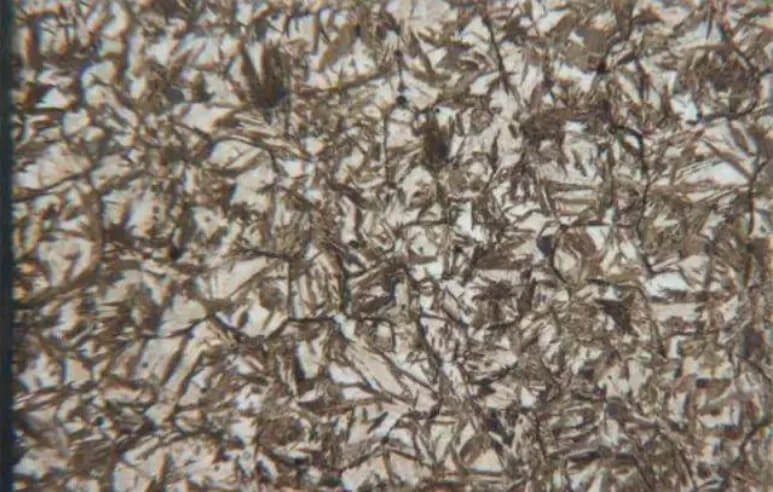

2.Tempering: The “Tough Way” of Steel

Tempering is a heat treatment process in which quenched steel is heated to a temperature below A1, kept warm, and then cooled to room temperature in a certain way. Tempering is a subsequent process of quenching, and its purpose is to eliminate internal stress, adjust mechanical properties, and stabilize structure and size. The following will analyze in detail what happens when you quench and temper iron?

Metallurgical diagram of tempered martensite

(1) Low temperature tempering (150℃~250℃):

Low temperature tempering is mainly used to maintain the high hardness and wear resistance of quenched steel, while appropriately reducing internal stress. During the tempering process, the supersaturated carbon atoms in the martensite begin to aggregate to form fine carbide particles. These carbide particles maintain a coherent connection with the martensite and have little effect on the hardness of the steel, but can reduce internal stress and improve the toughness of the steel.

(2) Medium-temperature tempering (300℃~500℃):

Medium-temperature tempering is mainly used to improve the elastic limit and yield strength of steel while maintaining a certain hardness and toughness. During the tempering process, martensite continues to decompose, carbide particles gradually grow, internal stress is further reduced, and the toughness of the steel is improved.

(3) High-temperature tempering (500℃~650℃):

High-temperature tempering is mainly used to obtain good comprehensive mechanical properties. During the tempering process, martensite is completely decomposed, carbide particles grow further, internal stress is basically eliminated, the hardness and strength of the steel are reduced, but the toughness and plasticity are significantly improved. The microstructure after high-temperature tempering is tempered troostite, which has good comprehensive mechanical properties.

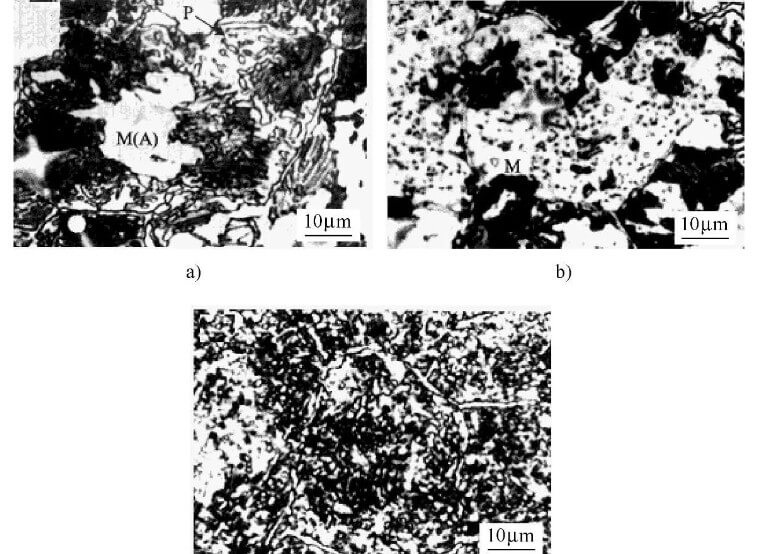

3.What happens when you quench and temper iron – physical and chemical changes during the process

Transformation diagram of structure during quenching and tempering of iron

(1) What happens when you quench and temper iron: formation and decomposition of austenite

During the quenching process, steel first forms austenite, and then transforms into martensite during rapid cooling. During the tempering process, martensite gradually decomposes, carbide particles precipitate and grow, and austenite gradually recovers.

(2) What happens when you quench and temper iron: carbon segregation and precipitation

During the low-temperature tempering process, the supersaturated carbon atoms in the martensite begin to segregate to form fine carbide particles. As the tempering temperature increases and the time increases, the carbide particles gradually grow and precipitate from the martensite.

(3) What happens when you quench and temper iron: elimination of internal stress

During the quenching process, due to rapid cooling, large internal stress is generated inside the steel. During the tempering process, the internal stress is gradually eliminated and the organizational structure of the steel gradually stabilizes.

(4) What happens when you quench and temper iron: Changes in mechanical properties

After quenching, the hardness and wear resistance of steel are significantly improved, but toughness decreases and internal stress increases. After tempering, the hardness and strength of steel decrease, but toughness and plasticity increase significantly, internal stress is basically eliminated, and mechanical properties are adjusted and optimized.

4.Application of quenching and tempering

(1) Improving hardness and wear resistance:

Quenching and tempering are widely used in high-hardness and high-wear-resistant workpieces such as cutting tools, measuring tools, and molds. For example, high-speed steel tools can obtain extremely high hardness and wear resistance after quenching and tempering, meeting the needs of cutting processing.

(2) Improving strength and toughness:

Quenching and tempering can improve the strength and toughness of various machine parts, making them less likely to break when subjected to large loads and impacts. For example, automobile gears, bearings and other parts can obtain good comprehensive mechanical properties and increase service life after quenching and tempering.

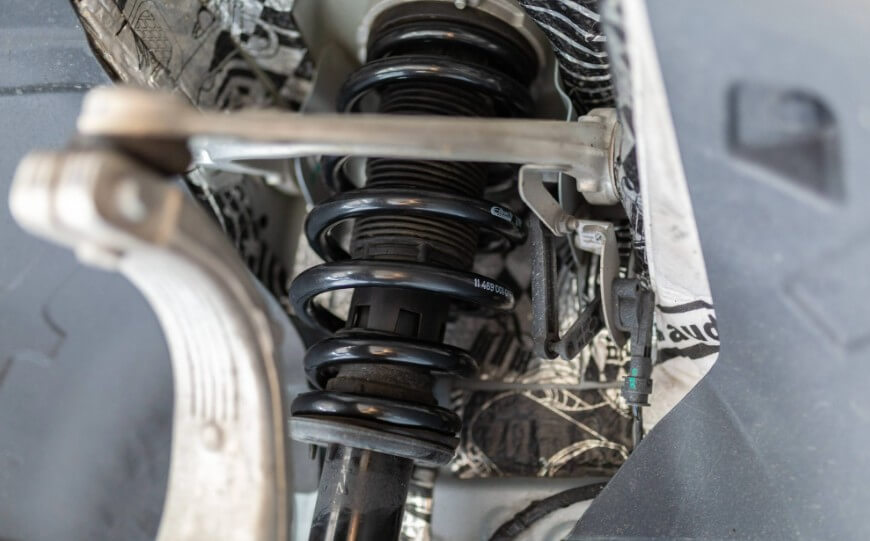

(3) Improve elasticity:

Quenching and tempering can improve the elasticity of various spring steels, making them less likely to fail when subjected to large deformation. For example, the springs in the automobile suspension system can obtain good elasticity and fatigue properties after quenching and tempering.

(4) Improve corrosion resistance and heat resistance:

Quenching and tempering can improve the corrosion resistance and heat resistance of stainless steel and heat-resistant steel, allowing them to maintain stable performance in harsh environments. For example, stainless steel parts in chemical equipment can improve their corrosion resistance after quenching and tempering.

5.Precautions for quenching and tempering

The above has analyzed in detail the relevant questions of “What happens when you quench and temper iron?” So what matters need to be paid attention to in order to achieve the performance transformation of steel?

(1) Heating temperature and time:

The heating temperature and time of quenching and tempering need to be reasonably selected according to factors such as the chemical composition of the steel, the size and shape of the workpiece, and the heating equipment. If the heating temperature is too high or the heating time is too long, the austenite grains will coarsen and affect the quenching effect; if the heating temperature is too low or the heating time is too short, the austenite will not be fully austenitized, which will also affect the quenching effect.

(2) Cooling rate:

The cooling rate of quenching must be greater than the critical cooling rate to avoid the transformation of austenite into pearlite or bainite during the cooling process. If the cooling rate is too fast, the internal stress will increase, which may cause deformation or cracking of the workpiece; if the cooling rate is too slow, the austenite will decompose and affect the quenching effect.

(3) Tempering temperature and time:

The tempering temperature and time need to be reasonably selected according to the performance requirements of the workpiece. If the tempering temperature is too low or the time is too short, the internal stress cannot be effectively eliminated and the mechanical properties cannot be adjusted; if the tempering temperature is too high or the time is too long, the hardness will drop too much and affect the performance of the workpiece.

6.Summary

In short, quenching and tempering are key links in the heat treatment process of steel. By reasonably controlling the heating temperature and time, cooling rate, and tempering temperature and time, ideal structure and performance can be obtained to meet the needs of different workpieces. Quenching and tempering processes play an important role in modern industry, providing a guarantee for the widespread application of steel materials.