- Video & Image Gallery

Casting Insights: A Visual Journey

Video Library

lvxun automated low pressure casting workshop

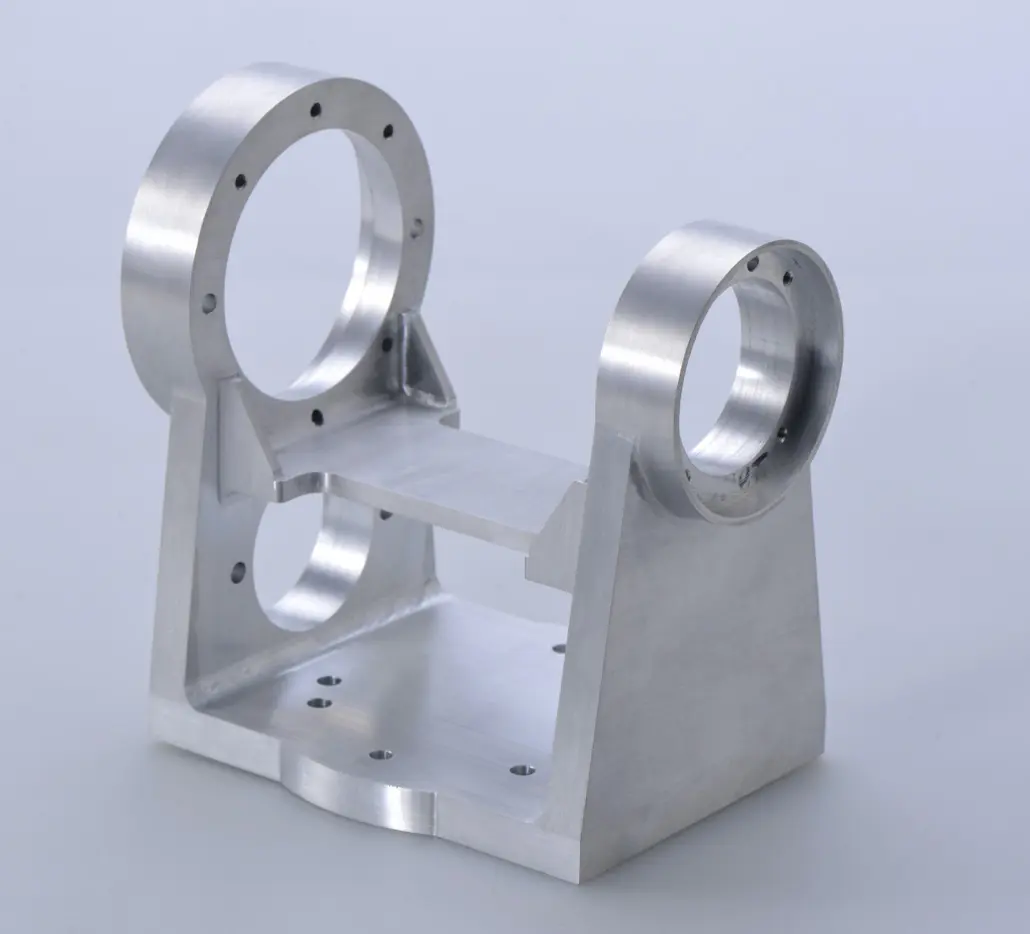

In order to expand our aluminum casting capacity, we invested in a low-pressure die-casting production line in our foundry in 2015. So far, we have 20 low-pressure die-casting machines ranging from 500KG to 800KG. These machines are PLC controlled and run fully automatically. Our low-pressure die-casting parts cover communication parts, electrical housings/casings, industrial robot parts, medical equipment parts, etc.

lvxun automated die-casting workshop

We started high pressure die casting in 2015. Currently, we have 20 die casting machines with weights ranging from 125 tons to 5000 tons. Our products cover automotive parts, medical device parts, electrical housings/casings, optoelectronic parts, radiators, hardware tool parts, etc., with weights ranging from 100G to 50KG. Our output can reach 5 tons per day.

lvxun automated gravity casting workshop

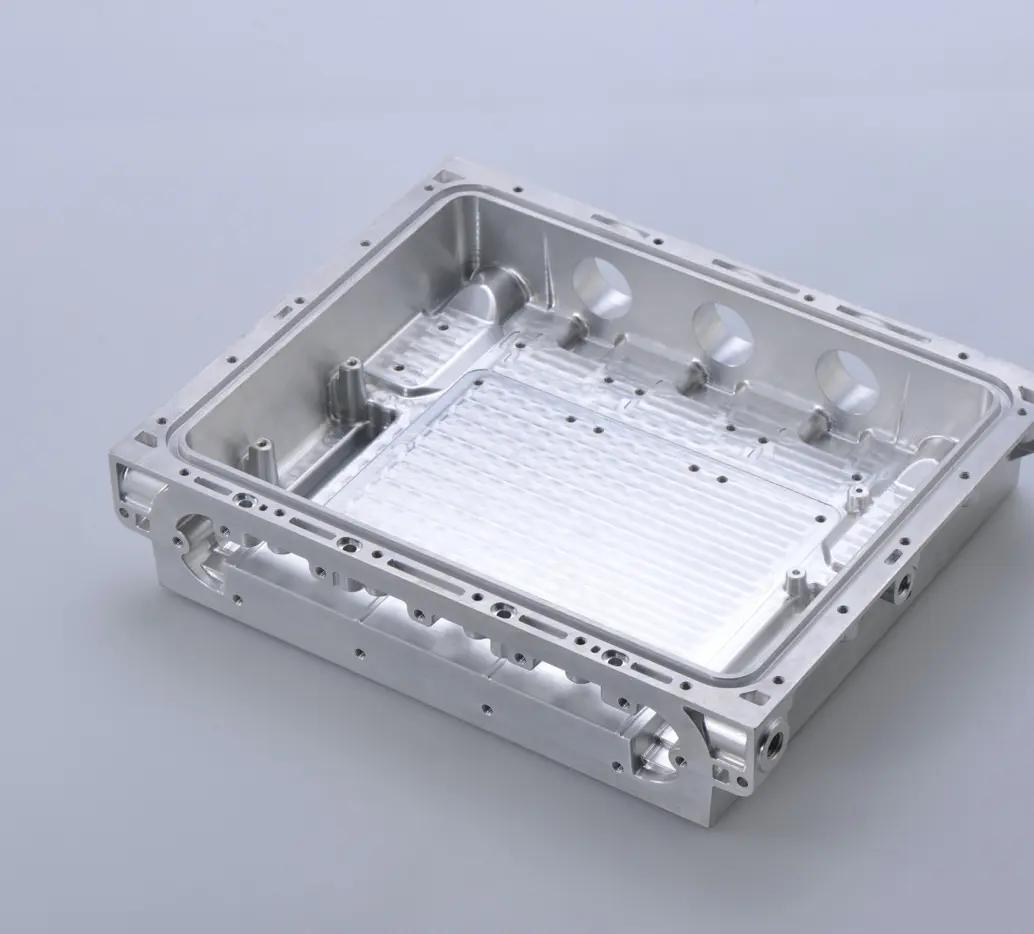

In 2015, we established a gravity die casting production line. At present, we have 6 tilting gravity die casting machines and 8 cylinder head gravity casting machines, which can produce 10 tons of castings per day. The weight ranges from less than 1 kg to 150 kg/piece. Our products cover automotive parts, medical device parts, electrical housings, optoelectronic parts, etc. We design and manufacture molds by ourselves. We have the ability to design, process and assemble molds.

Low pressure casting wheel

Main features of low pressure casting

1. High purity of castings.

2. Easy to cast large thin-walled complex castings.

3. Dense casting structure.

4. Improved metal liquid recovery rate, generally no riser required.

5. High dimensional accuracy of castings, generally CT6~CT7 level.

Investment Casting Animation

Over the past decade, we have cultivated 13 investment casting suppliers in China. So far, our suppliers have a daily production capacity of 8 tons. Our investment casting parts cover stainless steel castings, aluminum castings, carbon steel castings, brass castings, bronze castings, cobalt castings, tool steel castings, precious metal castings, special metals and nickel-based alloy castings.

Gravity Casting Mold Flow Analysis

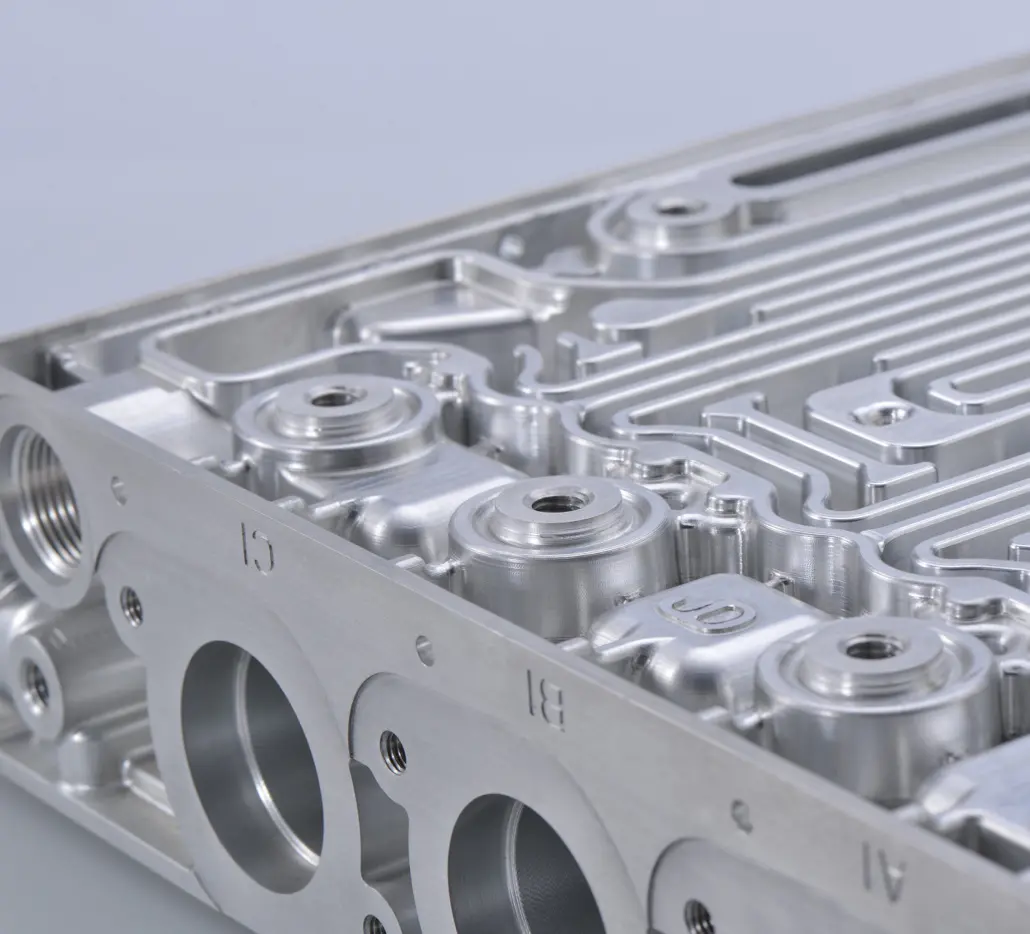

For some castings with complex geometries, we also have the capability of numerical computer simulation to help us achieve the most optimized design. Better design before mass production helps reduce the cost of trial and error through experimentation and put the design into production faster.

Image library