tech castings: the driving force behind the development of modern industry

As a traditional metal processing method, casting technology still plays an important role in the manufacturing of modern tech parts.Tech castings produced by casting technology, with their excellent performance and diverse applications, not only improve production efficiency, but also achieve technological breakthroughs in many fields. This article will introduce in detail the main aspects of the tech features of tech castings, innovative case descriptions, future development directions, and the current achievements and future development prospects of China’s casting industry.

1.What are the main aspects of tech castings?

(1) Material innovation:

Tech castings usually adopt advanced material science to develop alloy materials with special properties, such as light alloys, high-temperature alloys, etc. These materials have excellent performance in strength, heat resistance, corrosion resistance, etc., meeting the needs of high-end equipment manufacturing.

(2) Process technology:

Advanced casting processes such as lost wax casting, precision casting, digital intelligent casting, etc. are adopted. These processes can achieve precision molding of castings, improve the dimensional accuracy and surface quality of castings, and reduce the amount of subsequent processing.

(3) Intelligent production:

The application of intelligent technology in the production process of tech castings, such as big data computing center, 3DP manufacturing unit, intelligent forming unit, etc., has realized the automation and intelligence of casting production, and improved production efficiency and product quality.

(4) Green manufacturing:

Focus on environmental protection and sustainable development, adopt low-carbon and energy-saving production methods to reduce the impact on the environment. For example, the Guiyang tech Zone’s annual production of 500,000 aircraft engine castings project invested 30 million US dollars to build a new low-carbon plant.

(5) Industrial upgrading:

The development and application of tech casting has promoted the transformation and upgrading of traditional manufacturing industries. For example, Baoji tech Industrial Development Zone has filled the gap in high-level precision casting production capacity of large titanium components by establishing a light alloy material and its digital intelligent casting technology innovation center.

(6) Industrial chain collaboration:

The development of tech castings has promoted the collaborative innovation of the industrial chain. For example, Jining tech Zone has introduced a high-precision hot die forging production line to break the multi-station automation bottleneck technology and achieve close cooperation between upstream and downstream of the industrial chain.

(7) Economic benefits:

The production of tech castings not only improves the technical content and added value of products, but also brings significant economic benefits, and the operating income rises sharply.

Summary:

In summary, the tech nature of tech castings lies in the fact that they use advanced materials, process technologies and intelligent production methods, focus on green manufacturing and industrial upgrading, promote collaborative innovation in the industrial chain, and bring significant economic and social benefits.

2.Some examples of innovative development of tech castings

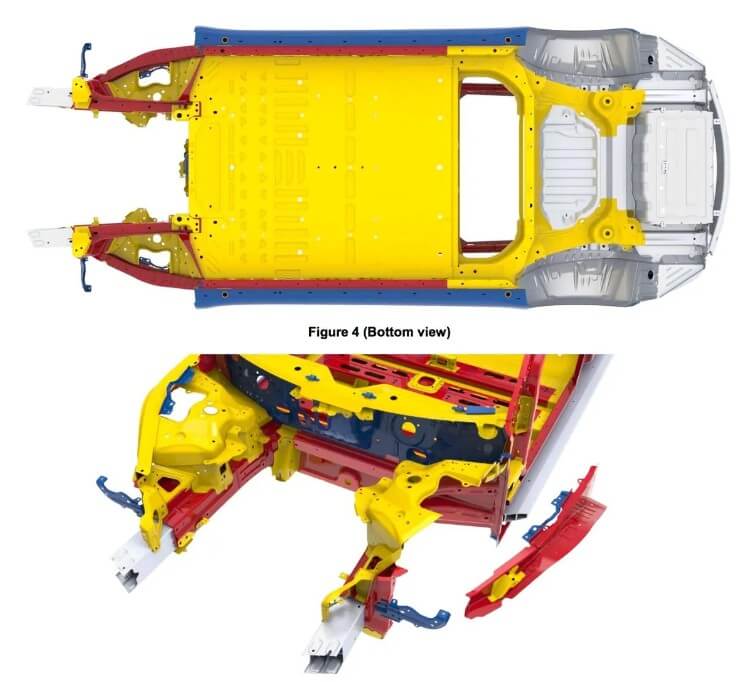

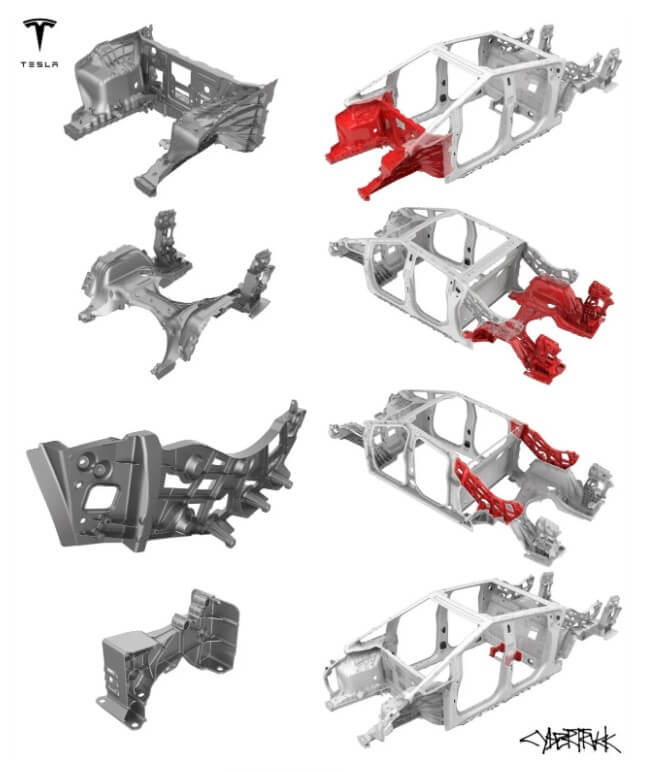

(1) Tesla’s one-piece casting body parts:

Tesla uses an innovative single-body casting process in its Model Y model, directly casting more than 70 components at the rear of the body into one. This process not only improves the structural strength and safety of the body, but also significantly reduces weight, reduces manufacturing costs, and improves the vehicle’s endurance.

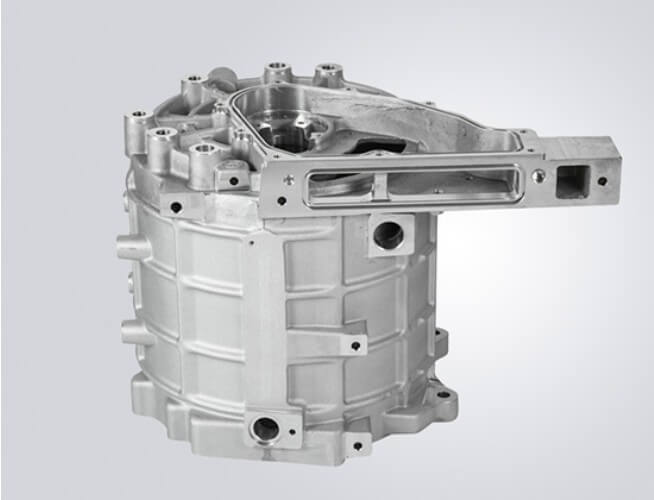

(2) New energy vehicle connector die castings:

With the development of new energy vehicles, die casting technology has been widely used in the manufacture of new energy vehicle connectors. These connectors need to have good high-voltage resistance, high-voltage interlocking technology, and small size to meet the high-voltage transmission needs of new energy vehicles. Guangzhou Yuanfang Precision Die Casting Technology Co., Ltd. is one of the companies that focuses on the research and development and production of such parts.

3.Future development direction of tech castings

With the rapid development of science and technology and the modernization process of the global manufacturing industry, tech castings, as an important part of modern industry, have attracted much attention for their future development direction. Tech castings not only play a key role in improving product quality and production efficiency, but also have important significance in promoting industrial greening and intelligence.

(1) Intelligent and automated production

Intelligence and automation are important trends in the development of tech castings. By introducing advanced computer control technology and robot operation, the casting process can be highly automated, reducing manual intervention and improving production efficiency and product quality.

(2) Environmental protection technology

Environmental protection is another important direction for the development of tech castings. With the increasing global attention to environmental protection, the casting industry must adopt more environmentally friendly production processes and technologies to reduce pollution emissions and achieve sustainable development.

(3) Lightweight and high-performance materials

With the lightweight development trend in industries such as automobiles and aerospace, the application of high-performance lightweight alloy materials will become more and more extensive. Aluminum-based composite materials, magnesium alloys and other materials have shown great potential in the manufacture of important components such as automotive drive rods, cylinder blocks, and cylinder liners due to their excellent performance.

(4) Precision casting technology

Precision casting technology is the key to improving the dimensional accuracy and surface quality of castings. In the future, as the manufacturing industry develops towards precision and miniaturization, the demand for precision castings will continue to increase. Precision casting technology can not only produce castings close to the final shape and reduce the amount of subsequent processing, but also produce complex, high-temperature, and corrosion-resistant castings to meet special application requirements.

(5) Digital and information management

Digital and information management is an important means to improve the competitiveness and production efficiency of casting companies. By introducing CAD/CAM/RPM technology and CIMS technology, process design and mold processing can be digitized, improving design efficiency and manufacturing accuracy. At the same time, using Internet technology and big data analysis, real-time monitoring and optimization management of the production process can be achieved, improving production efficiency and product quality.

(6) Green casting concept

In the future, the green casting concept will become an important development direction of the casting industry. By promoting green casting concepts such as low-carbon production, quality improvement, energy conservation and emission reduction, the sustainable development of the casting industry can be achieved.

Summary:

In short, the future development direction of tech castings will focus on intelligence, environmental protection, lightweight, precision, digitalization and green casting. Through continuous technological innovation and process improvement, tech castings will provide more high-quality, efficient and environmentally friendly products and services for the development of modern industry.

4.Current achievements and future development prospects of China’s casting industry

In recent years, China’s casting industry has made remarkable achievements. Not only has it achieved steady growth in market size, but its technical level has also been significantly improved, making it an important participant in the global casting market.

(1) Current achievements

1) Market size continues to expand:

According to data, the total output value of China’s casting industry in 2022 was RMB 985.7 billion, a year-on-year increase of 6.4%. This data shows that in the context of slowing global economic growth, China’s casting industry still shows strong resilience and vitality, and has achieved rapid growth in different fields.

2) Significant technological progress:

China’s tech castings have made continuous breakthroughs in technology, and product quality and performance have been steadily improved. For example, the application areas of ductile iron are constantly expanding, and it can be used in internal combustion engines, agricultural machinery, wind power castings, cast pipes and pipe fittings. In addition, aluminum (magnesium) alloys are increasingly used in new energy vehicles and lightweight automobile manufacturing.

3) Export growth:

China has gradually become one of the world’s largest exporters of castings. In 2020, China’s casting exports amounted to 1.649 million tons. Although it was slightly lower than in 2019, the overall export volume remained at a high level. This shows that Chinese castings have strong competitiveness in the international market.

(2) Development prospects

1) Further release of market potential:

With the rapid development of China’s economy and the upgrading of its manufacturing industry, the market demand for the casting industry will continue to grow. It is estimated that by 2025, the market size of China’s steel casting industry will reach more than 50 billion yuan. In particular, in the fields of automobiles, machinery, electronics, etc., the application of castings will be more extensive.

2) Technological innovation drives industry development:

In the future, China’s casting industry will carry out technological innovation in many fields, including new material research and development, casting process improvement, etc. These technological innovations will improve the performance and quality of tech casting products, reduce production costs, and enhance the competitiveness of the industry.

3) Policy support and environmental protection requirements:

The government has continuously increased its support for the foundry industry, and promoted the healthy development of the industry through policy guidance and technical standard improvement. At the same time, with the enhancement of environmental awareness, the concept of green casting has gradually been promoted, and the proportion of waste (old) sand recycling and utilization of foundry enterprises has increased year by year, which will promote the sustainable development of the entire industry.

4) Enhanced international competitiveness:

With the advancement of technology and the improvement of product quality, the international competitiveness of China’s casting industry will be further enhanced. The independent production of key tech castings required for high-end equipment will reduce dependence on external markets and increase the market share of domestic casting companies.

Summary:

In summary, based on the existing achievements, China’s casting industry has broad prospects for future development. The growth of market size, the promotion of technological innovation, and the improvement of policy support and environmental protection requirements will bring new development opportunities to the casting industry. China’s casting industry is expected to occupy a more important position in the global market.

5.Summary

Tech castings are becoming an important driving force for the development of modern industry due to their advantages such as high precision, excellent performance, integrated complex structure, high production efficiency and wide application. With the continuous advancement of technology and the improvement of product quality, tech castings will play an important role in more fields.

If you are looking for an experienced casting manufacturer, Lvxun is your ideal choice. The Lvxun team is well-equipped to provide high-quality casting solutions. If you need more information or to discuss your needs with us, please feel free to contact us.