Steel color: from logo to application

In people’s general perception, steel color is always associated with cold, hard silver-gray. In fact, the world of steel is far more colorful than we imagine. Behind each color lies a unique identity and function. This article will take you to unveil the mystery of steel color and explore the causes and related applications of different steel colors.

1.Ordinary carbon steel color

(1) Silver-gray

Silver-gray is the most common color of ordinary carbon steel. This color mainly comes from a layer of oxide film formed on the surface of the steel. In the natural environment, steel will undergo oxidation reaction after contact with oxygen, forming a dense iron oxide film, which reflects light and makes the steel appear silver-gray. Silver-gray steel is widely used in building structures, machinery manufacturing and other fields.

(2) Dark gray

Dark gray usually appears in carbon steel with a high carbon content. As the carbon content increases, the strength and hardness of the steel increase, but the plasticity and toughness decrease. The oxide film formed during the oxidation process of this steel is darker in color and appears dark gray. Dark grey steel is often used to make tools and wear-resistant parts.

(3) Blue-black

Blue-black is the colour of steel after it is cooled after being heated at high temperatures. At high temperatures, a layer of ferroferric oxide is formed on the surface of the steel. This compound is magnetic and has a blue-black colour. Blue-black steel is often used for equipment and components in high temperature environments, such as boilers and high-temperature pipes.

2.Alloy Steel Color

(1) Golden yellow

Some alloy steels containing elements such as nickel and chromium appear golden yellow. The addition of nickel and chromium not only improves the corrosion resistance of the steel, but also forms a layer of oxide film with a special luster on its surface, which appears golden yellow. This type of steel is often used for high-end decorative materials and chemical equipment.

(2) Rose red

Rose red alloy steel usually contains a higher proportion of chromium and manganese. Chromium gives the steel excellent corrosion resistance, while manganese makes its colour tend to be rose red. Rose red steel is often used to make decorative building components and furniture.

(3) Bronze color

Bronze alloy steel generally contains copper. The addition of copper not only improves the strength and wear resistance of the steel, but also makes its surface appear bronze after oxidation. This type of steel is often used to make artworks and decorations.

3.Stainless steel color

(1) Silvery white

Silvery white is the most typical color of stainless steel. Stainless steel contains a high proportion of chromium and nickel. These two elements form a dense oxide film on the surface of the steel, which has extremely strong corrosion resistance. Silvery white stainless steel is widely used in food processing, medical equipment and architectural decoration.

(2) Grayish white

Off-white stainless steel is usually formed by special treatment during the production process. This treatment enhances the surface hardness and abrasion resistance of the steel and makes the steel color inclined to grayish white. Off-white stainless steel is commonly used in industrial equipment and machine parts.

(3) Black

Black stainless steel is formed by a black oxide film on the surface of the steel through surface treatment technology, such as blackening or black plating. Black stainless steel not only has excellent corrosion resistance, but also has a unique decorative effect. It is often used in high-end construction and decoration projects.

4.Specially treated steel colors

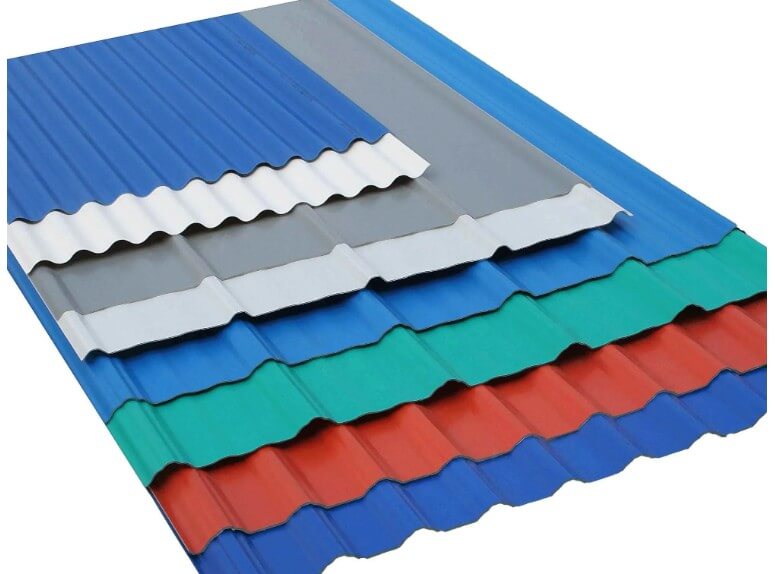

(1) Color Coated Steel Plate

Color coated steel plate is a steel plate with an organic coating on its surface. Through different coating materials and processes, it can form various colors, such as red, blue, green, etc. Color coated steel plate not only has good decorative properties, but also has the advantages of corrosion resistance and strong weather resistance. It is widely used in building roofs, walls and home appliance shells.

(2) Alu-zinc coated steel plate

Alu-zinc coated steel plate is a steel plate with an aluminum-zinc alloy on its surface. This steel has good corrosion resistance and heat resistance. The color of lu-zinc coated steel plate is usually silver-gray or blue-gray, and is often used in building roofs and wall materials.

(3) Hot-dip galvanized steel plate

Hot-dip galvanized steel plate is a steel plate with a layer of zinc on its surface. Zinc reacts with the steel plate surface at high temperature to form a zinc-iron alloy layer with good corrosion resistance. The color of hot-dip galvanized steel plate is usually silver-white or gray-white, and is often used in building structures and industrial equipment.

5.Colors of other types of steel

(1) Patterned steel plates

Patterned steel plates are made by pressing various patterns on the surface of steel plates to give them good anti-slip properties. The color of patterned steel plates is the same as that of ordinary steel plates, usually silver-gray or dark gray, and are often used in places such as industrial platforms and stair treads.

(2) Steel pipes

The color of steel pipes depends on their material and surface treatment. Seamless steel pipes are usually silver-gray or dark gray, while welded steel pipes may be treated with anti-corrosion to present different colors, such as black, red or green. Steel pipes are widely used in pipeline systems for transporting liquids and gases.

(3) Section steel

Section steel includes angle steel, channel steel, I-beam, etc., and its color is the same as that of ordinary steel plates, usually silver-gray or dark gray. Section steel is often used in fields such as building structures and bridge engineering.

6.Factors affecting steel color

(1) Chemical composition

The chemical composition of steel is an important factor affecting its color. The addition of different elements will change the color of the oxide film of steel, such as nickel and chromium make steel appear silvery white or golden yellow, and copper makes steel appear bronze.

(2) Production process

The production process of steel will also affect its color. For example, high-temperature heating and cooling will form oxide films of different colors on the surface of steel, while surface treatment technologies such as plating and coating can change the steel color.

(3) Environmental conditions

Environmental conditions also have an effect on steel color. In a humid or corrosive environment, rust of different colors, such as reddish brown or green, is easily generated on the surface of steel.

7.The role of steel color in actual production and application

(1) Determination of heat treatment state

During the heat treatment process, the steel color changes with the temperature.For example, during the quenching process, an oxide film will form on the surface of steel, and its color will show different colors with different quenching temperatures. By observing the color of the steel, it is possible to preliminarily determine whether its quenching temperature is appropriate, thereby evaluating its heat treatment effect.

(2) Evaluation of surface treatment effect

For steel that has been surface treated, such as electroplating, spraying, etc., its surface color and gloss can reflect the effect of the surface treatment. High-quality surface treatment usually makes the steel surface present a uniform and smooth color and gloss; while low-quality surface treatment may have problems such as color difference and peeling.

(3) Surface defect detection

By observing the color change of the steel surface, it can be judged whether it has defects. For example, defects such as cracks, scars, and folds usually show a different color from the normal steel surface.

For example, cracks may show dark lines in the sun, while scars may appear red or brown due to different degrees of oxidation.

(4) Corrosion degree evaluation

After the steel is corroded, rust products of different colors will be generated on the surface. For example, the surface may appear yellow or orange-yellow in case of mild corrosion, red or reddish brown in case of moderate corrosion, and black or gray-black in case of severe corrosion. The corrosion degree of the steel can be roughly evaluated based on the color change of the steel.

8.Conclusion

The color of steel is not just a single silver-gray, but is rich and varied. Each color of steel has a unique identity and function, providing important support for the development of modern industry.