Casting Application

Main features of low pressure casting

1. High purity of castings.

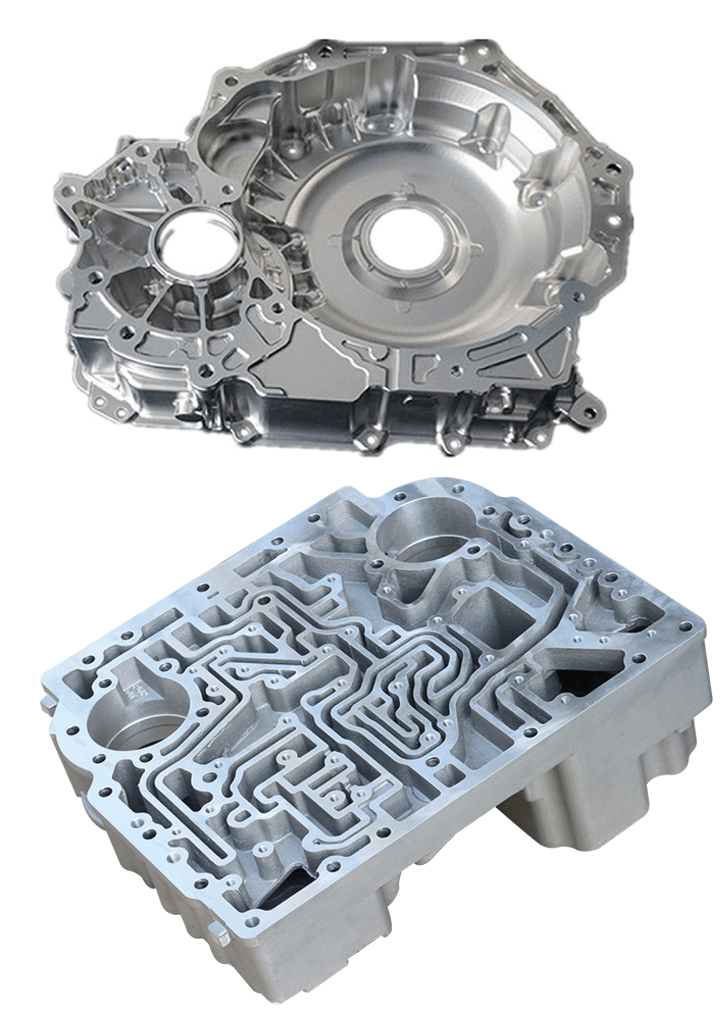

2. Easy to cast large thin-walled complex castings.

3. Dense casting structure.

4. Improved metal liquid recovery rate, generally no riser required.

5. High dimensional accuracy of castings, generally CT6~CT7 level.

DEDICATED TO INNOVATION

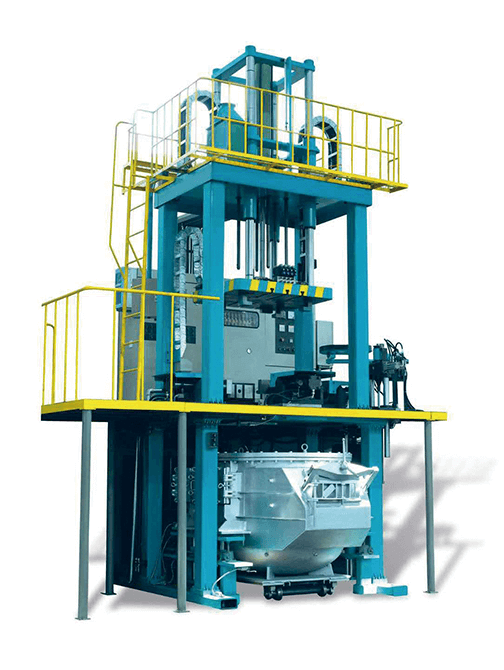

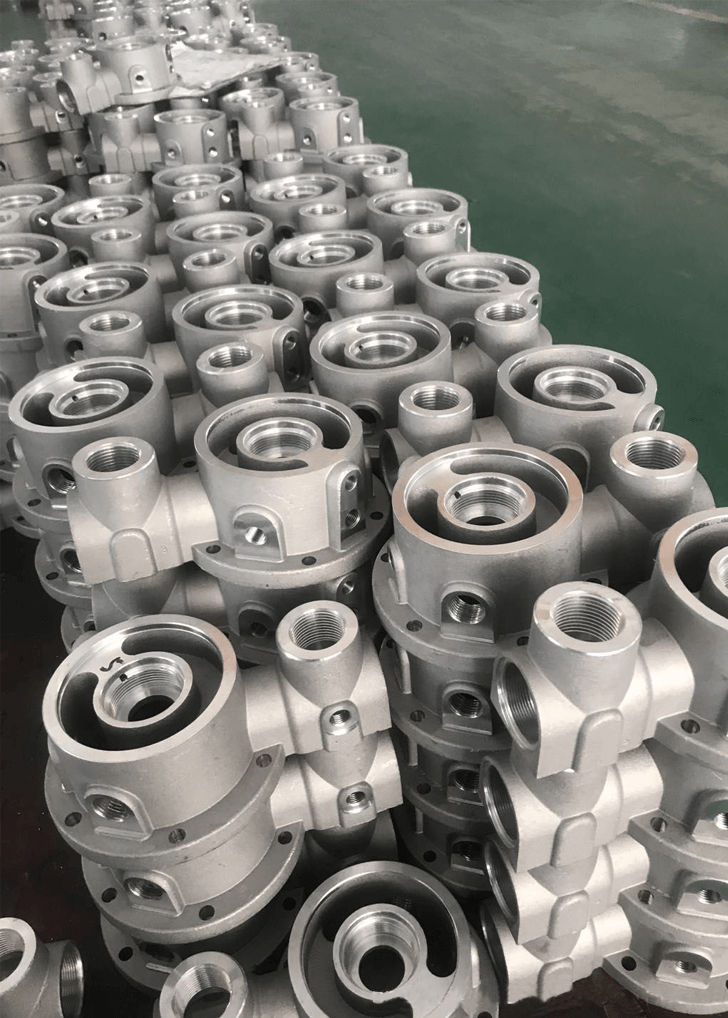

In order to expand our aluminum casting capacity, we invested in a low-pressure die-casting production line in our foundry in 2015. So far, we have 20 low-pressure die-casting machines ranging from 500KG to 800KG. These machines are PLC controlled and run fully automatically. Our low-pressure die-casting parts cover communication parts, electrical housings/casings, industrial robot parts, medical equipment parts, etc.

The Advantages Of Low Pressure Die Casting Process

High efficiency — Alike high pressure die casting process, this process is easy to achieve full automation.

High quality — Parts mde by this process are with some excellent characteristics as tight tolerance, smooth surface, good mechanical properties.

High material use factor — Since the molten metal will goes back into crucible after pressure relieve, the material use factor is much higher than other permanent die casting processes.

Our material range

ASMT standards: A319, A356, A357, A413.

National standards: ZL101, ZL101A, ZL102, ZL107.

British standards: LM6, LM20, LM25.

EN standards: EN AC-42100, EN AC-42200, EN AC-43000, EN AC-43200, EN AC-43300, EN AC-43400, EN AC-44200, EN AC-44300, EN AC-46000, EN AC-46200.

High purity castings

In the low-pressure casting process, the molten metal is forced into the mold cavity through the riser at the bottom of the crucible, completely avoiding the slag floating on the surface from entering the mold cavity. Therefore, the purity of the castings cast by this process is higher than that of other casting processes.

The mold for low-pressure casting generally does not have a riser. The molten metal in the riser tube is depressurized and returned to the crucible, so the molten metal recovery rate can be as high as 90% or more.