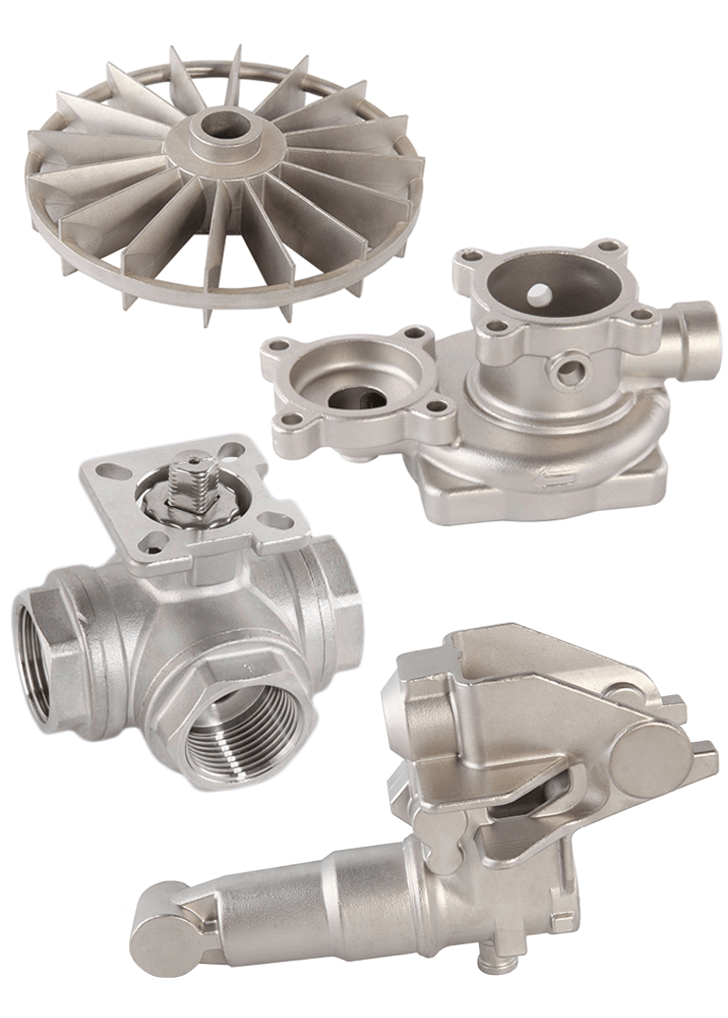

Casting Application

Investment casting generally refers to using fusible materials (wax materials, plastics, etc.) to make an accurate fusible model, applying several layers of refractory paint on the model, drying and hardening into a one-piece shell, and then heating it to lose the shell. Then the model is baked at high temperature to become a refractory shell. Liquid metal (such as stainless steel, aluminum, cobalt, carbon steel, brass, bronze, etc.) is poured into the shell and cooled to form a casting. This process is best used for small precision metal parts with complex geometries.

DEDICATED TO INNOVATION

Over the past decade, we have cultivated 13 investment casting suppliers in China. So far, our suppliers have a daily production capacity of 8 tons. Our investment casting parts cover stainless steel castings, aluminum castings, carbon steel castings, brass castings, bronze castings, cobalt castings, tool steel castings, precious metal castings, special metals and nickel-based alloy castings.

Various and complex shapes

Investment casting provides consistent and repeatable close tolerances and complex channels and profiles. Many of these configurations are impossible to produce. For example, places that machine tools cannot reach. Achieving net-shape or near-net-shape castings can significantly reduce post-cast machining costs. Investment casting is a good alternative to welded or assembled components. Many components can be combined into a single casting. The more components that are combined, the more efficient the manufacturing process becomes. Converting a multi-piece assembly to a single investment cast often improves dimensional accuracy and reduces part complexity.

Our material range

Stainless Steel:302, 303, 304, 304L, 310, 316, 316L, 5360, 321, 330, 347,410, 415, 416, 420, 440C, 15-5, 17-4, & CF10MC.

Cobalt:CO6, CO12, CO21.

Carbon Steel:1010, 1018, 1020, 1025, 1030, 1040, 1045, 1050, 1060,4130, 4340, 4140, 4150, 4615, 6150, 8620, 8630, 8635, & 8640

Aluminum:A356.

Brass:C875, C876.

Tool Steel:O-1, A-2, D-2, H-13, M-2, S-5, & S-7.

Nickel:47-50, UDIMET 700, HASTELLOY X, & NI RESIST.

Bronze:C95400, C86500, C86300, C952, & C956.

Duplex:CD4MCU, 2205.

Excellent product quality

Investment castings are typically able to hold tolerances of +/- 0.005 inches per inch. However, under certain conditions, tolerances of +/- 0.003 can be achieved. Tighter tolerances beyond typical investment casting standards can be achieved through machining processes. The cost of any part increases as its dimensional accuracy requirements increase. Whether it is a casting, machined component, or a fabricated part. A careful design review will allow for modifications to tolerances, undercuts, blind holes, etc. to achieve higher production yields and lower part costs. If tighter tolerances than casting tolerances are required, then the investment casting will require less machining than a conventional casting or fabricated part.