Casting finishing

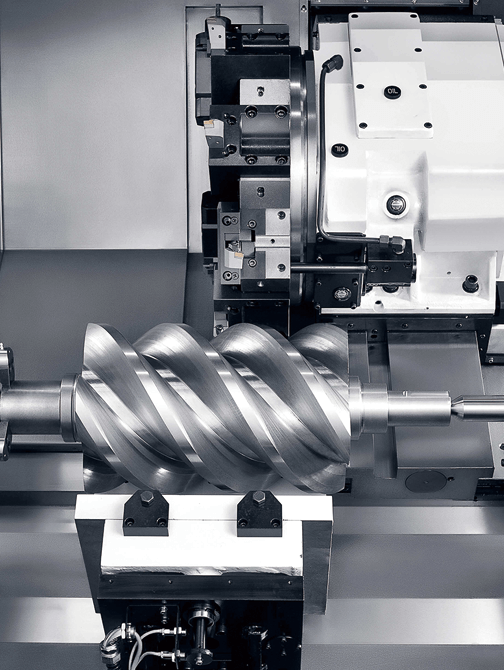

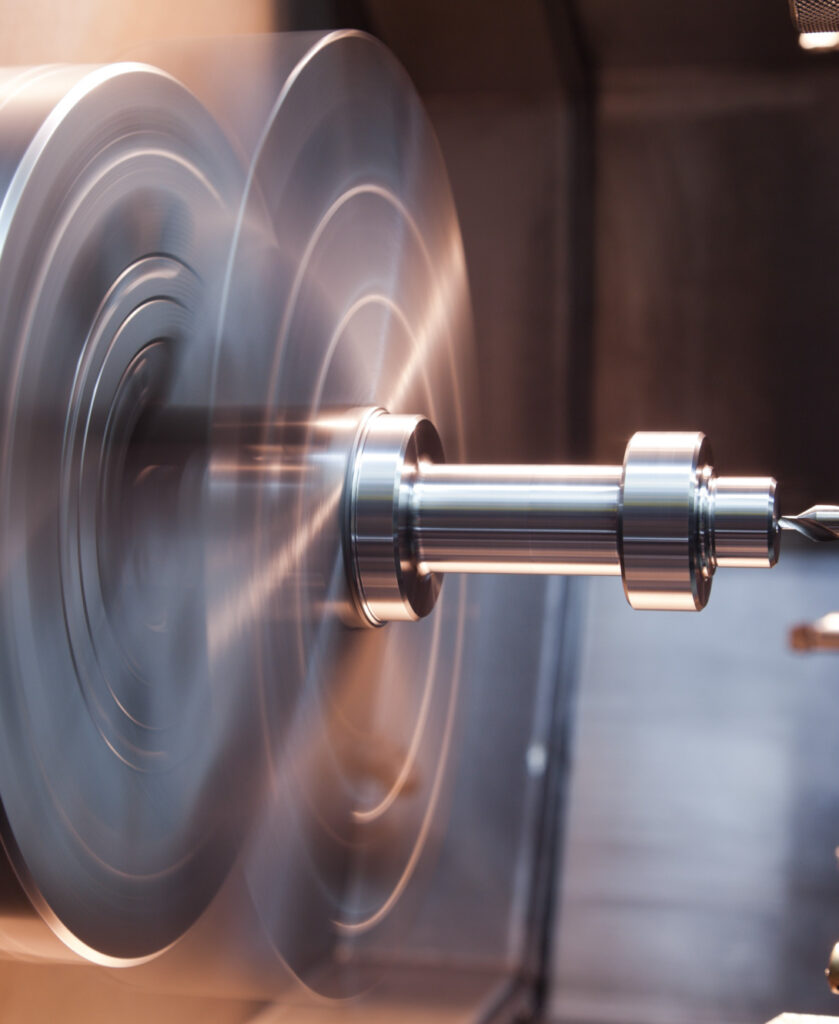

CNC turning is a subtractive manufacturing technique that refers to the process of removing material from a (usually) cylindrical stock – although CNC turning can also be performed on a variety of stock shapes such as hexagonal or square bars. The machine rotates the workpiece while the tool moves to engage and remove material until the desired shape is achieved.

DEDICATED TO INNOVATION

We have 12 four-axis turning centers, 24 turning and milling centers, 20 Swiss turning centers and 10 vertical turning centers. Our engineers can select the turning equipment that best suits your production and manufacturing needs based on the structural characteristics and MOQ characteristics of the parts to maximize machining efficiency and reduce costs.

Diversified Turning

4 axis cnc turning:The 4-axis turret CNC turning tool has a small overrun, and supports axial end face and longitudinal simple geometric structure milling.

CNC turning and milling:CNC milling and turning is the only processing equipment that can clamp all cutting steps at one time.

Swiss Turning Machining:Swiss turning is suitable for machining micro precision parts. It originated from the production of precision small parts in the industry.

CNC Tool Lathe Machining:The CNC lathe has high tool change efficiency, fast cutting speed and small tool capacity.

Parts machining standards

We manufacture your custom parts according to strict manufacturing standards and ensure all parts and processes adhere to the Lvxun Standard. A thorough verification of these requirements is included in our inspection report that we ship with every order.

PO consistent:We ensure that every part after machining is as specified in the PO as customer requirements.

Quality check:Prior to MP shipment to ensure that each part meets order specifications and Lvxun standards.

Require consistent:Ensure conformance of parts and any required documentation prior to dispatching the order.

Technically feasible values

| Feature | Recommended size | Feasible size |

|---|---|---|

| Min. feature size | Ø 2.5 mm | Ø 0.50 mm |

| Internal edges | R 8 mm | R 0.25 mm |

| Minimum wall thickness | 0.8 mm (for metals) 1.5 mm (for plastics) | 0.5 mm (for metals) 1.0 mm (for plastics) |

| Holes | Diameter: standard drill bit sizes Depth: 4 x diameter | Diameter: Ø 0.5 Depth: 10 x diameter |

| Threads | Size: M6 or larger Length: 3 x diameter | Size: M2 |