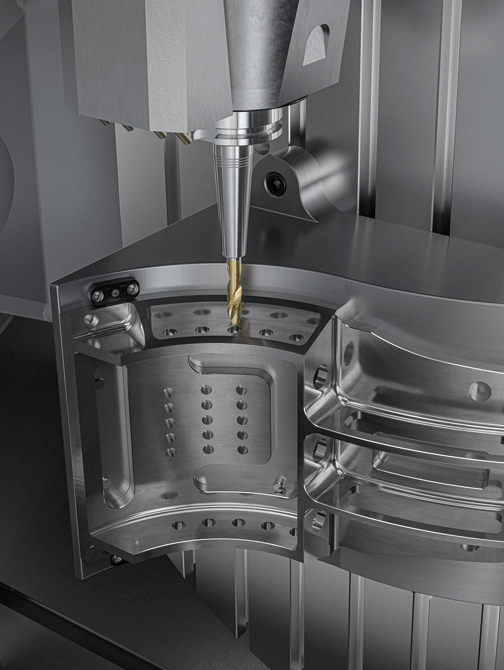

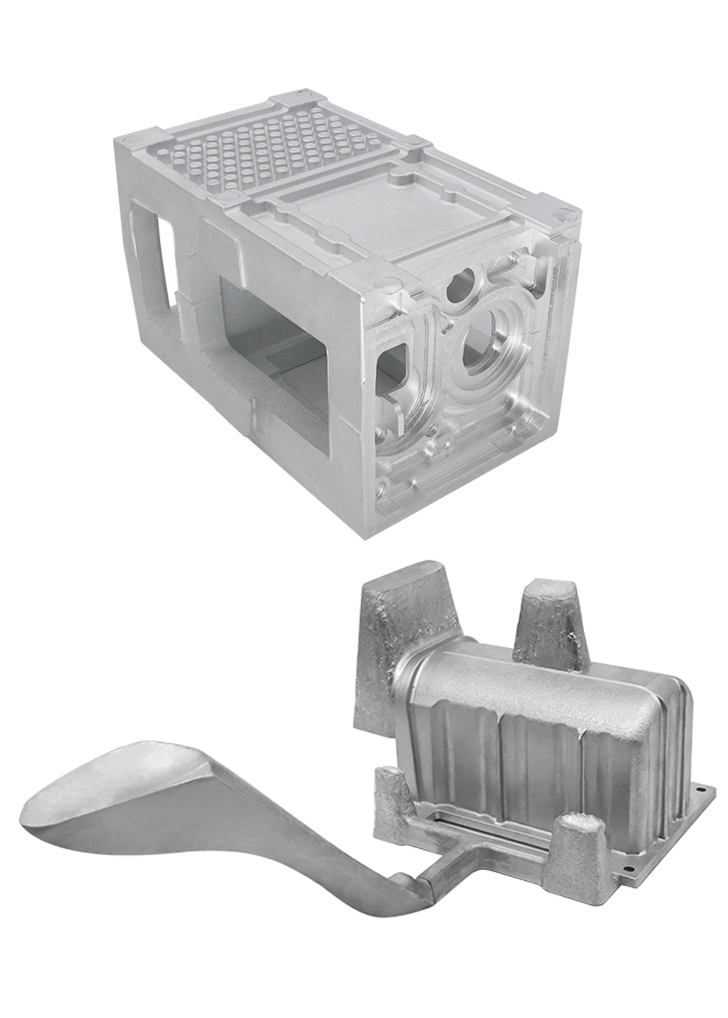

Casting finishing

CNC Milling has a rotating cylindrical cutter head and multiple chip flutes, usually called end mills or end mills, which can move along different axes and are used to process narrow spaces, grooves, outer contours, etc. The machine tool for milling is called a milling machine, and a CNC milling machine is usually a CNC machining center.

DEDICATED TO INNOVATION

Our factory has more than 100 machines supporting 3/4/5 axis CNC milling and horizontal CNC milling services to help you quickly get the finishing of your casting parts. At the same time, we provide 3/4/5 axis CNC milling and horizontal CNC milling services to quickly machine batches of custom CNC milled parts.

Diversified CNC Milling

5 axis CNC milling:5-axis machining provides manufacturing feasibility for designing parts with very complex 3D geometries with high economic efficiency.

4 axis CNC milling:Four-axis milling is suitable for mass production of polyhedral milled parts, milling three three-dimensional surfaces at a time.

3 axis CNC Milling:3-axis milling is the most widely used CNC machining process and is generally used for machining simple parts. Equipment cost is low.

Horizontal CNC Milling:Horizontal CNC milling is a CNC milling method in which the cutting spindle is kept parallel to the table. The rigidity of the machine tool is superior.

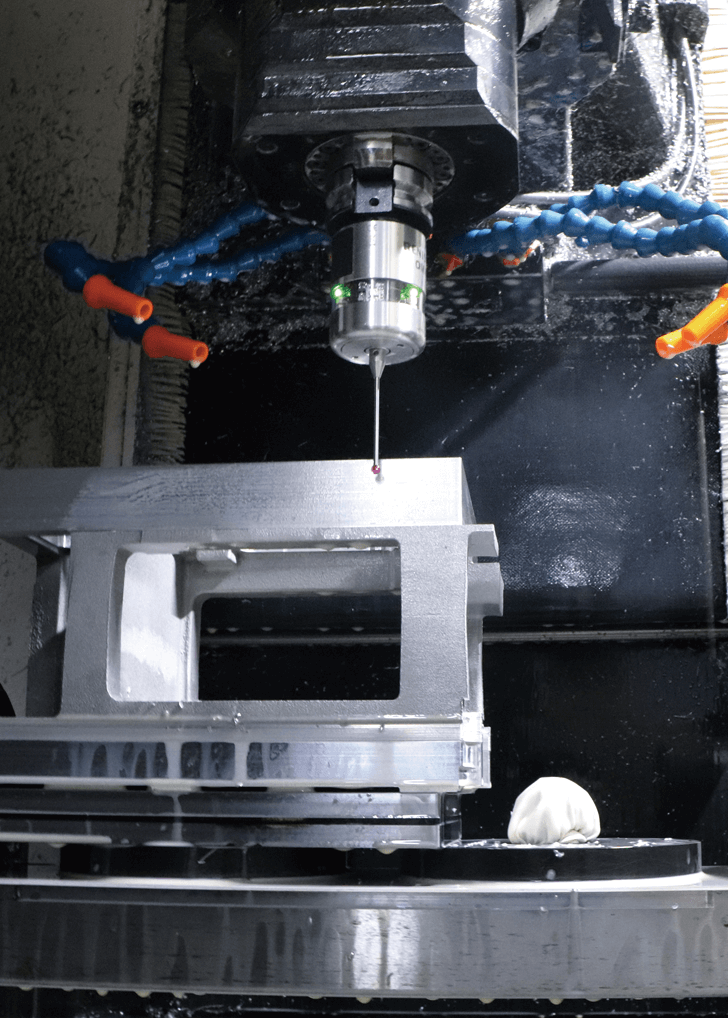

Parts machining standards

We manufacture your custom parts according to strict manufacturing standards and ensure all parts and processes adhere to the Lvxun Standard. A thorough verification of these requirements is included in our inspection report that we ship with every order.

PO consistent:We ensure that every part after machining is as specified in the PO as customer requirements.

Quality check:Prior to MP shipment to ensure that each part meets order specifications and Lvxun standards.

Require consistent:Ensure conformance of parts and any required documentation prior to dispatching the order.

Technically feasible values

| Feature | Recommended size | Feasible size |

|---|---|---|

| Min. feature size | Ø 2.5 mm | Ø 0.50 mm |

| Internal edges | R 8 mm | R 0.25 mm |

| Minimum wall thickness | 0.8 mm (for metals) 1.5 mm (for plastics) | 0.5 mm (for metals) 1.0 mm (for plastics) |

| Holes | Diameter: standard drill bit sizes Depth: 4 x diameter | Diameter: Ø 0.5 Depth: 10 x diameter |

| Threads | Size: M6 or larger Length: 3 x diameter | Size: M2 |