Detailed explanation of seven annealing processes

Annealing process is an important method in metal heat treatment. Through the heating and cooling process, the microstructure of metal materials is changed, thereby improving their mechanical properties. This article will introduce in detail the principle, purpose, classification and application of annealing process in different industrial fields.

1.Principle of annealing process

The basic principle of annealing is to heat the metal to a certain temperature, keep it warm for a period of time, and then slowly cool it. This process can rearrange the crystal structure inside the metal, eliminate internal stress, refine the grains, and thus improve the ductility, toughness and cutting performance of the metal.

2.Purpose and function of annealing process

(1) Reduce hardness and strength:

Through annealing, the hardness and strength of metal materials can be reduced, and their plasticity can be improved, thereby facilitating subsequent cutting and cold deformation processing.

(2) Eliminate or reduce residual stress:

Residual stress may be generated during the casting, forging, rolling and welding of metal materials. Annealing process can effectively eliminate or reduce these stresses, stabilize the size, and reduce deformation and crack tendency.

(3) Refine the grains and adjust the structure:

During the annealing process, the grains of the metal material can be refined and the structure can be adjusted, thereby eliminating the structural defects and improving the mechanical properties of the material.

(4) Uniform material structure and composition:

Through annealing, the structure and composition of the metal material can be uniform, and the structure can be prepared for subsequent heat treatment (such as quenching and tempering).

(5) Improve material properties:

The ultimate goal of annealing is to improve the performance of the material so that it meets specific usage requirements, such as improving toughness and reducing brittleness.

3.Classification of annealing processes

According to different heating temperatures and cooling methods, the annealing process can be divided into the following types:

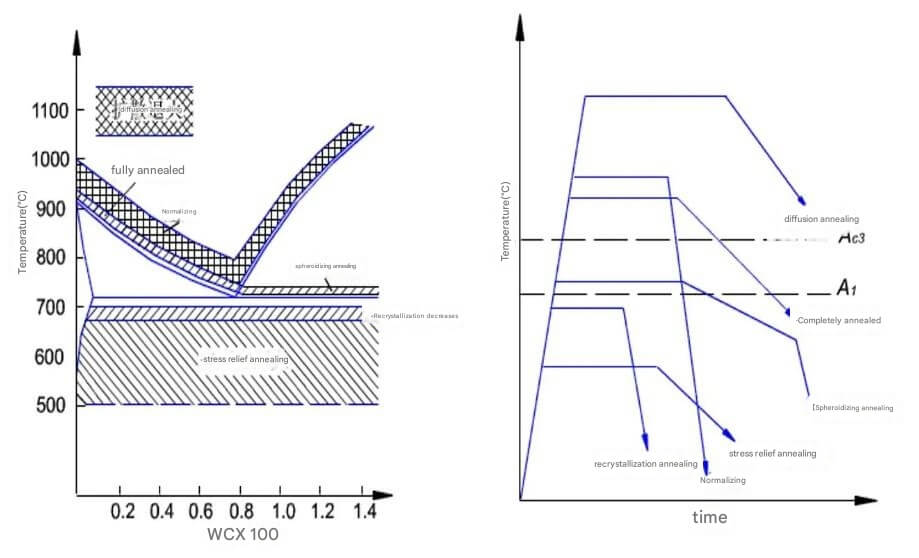

Left: Heating temperature range; Right: Process curve

(1) Complete annealing:

Heat the hypoeutectoid steel to 20~30℃ above Ac3, keep it warm for a period of time, and then slowly cool it to obtain a heat treatment process close to the equilibrium structure. It is suitable for medium carbon steel and low and medium carbon alloy steel castings, forgings and hot rolled profiles, and sometimes also for welded parts.

(2) Isothermal annealing:

Heat the steel to a temperature higher than Ac3 (or Ac1), keep it at this temperature for a suitable period of time, then quickly cool it to a certain temperature in the pearlite zone, and keep it isothermally to transform austenite into pearlite, and then air cool it to room temperature. Applicable to high carbon steel, alloy tool steel, and high alloy steel.

(3) Incomplete annealing:

Heat the steel to Ac1Ac3 (hypoeutectoid steel) or Ac1Accm (hypereutectoid steel), keep it at this temperature, and then slowly cool it to obtain a heat treatment process with a nearly balanced structure. Applicable to hypereutectoid steel to obtain spherical pearlite structure, so as to eliminate internal stress, reduce hardness, and improve machinability.

(4) Spheroidizing annealing:

A heat treatment process that spheroidizes carbides in steel to obtain granular pearlite. Applicable to eutectoid steel and hypereutectoid steel, such as carbon tool steel, alloy tool steel, bearing steel, etc.

(5) Diffusion annealing (homogenization annealing):

Heat the ingot, casting or forging to a temperature slightly below the solidus for a long time, then slowly cool it to eliminate the chemical composition unevenness. Applicable to some high-quality alloy steels and alloy steel castings and ingots with severe segregation.

(6) Stress relief annealing:

Heat the steel to a temperature below Ac1 (generally 500~650℃), keep it warm, and then cool it with the furnace. Applicable to eliminate the internal stress of steel castings and welded parts.

(7) Recrystallization annealing:

An annealing method applied to metals and alloys that have undergone cold deformation. The purpose is to transform the internal structure of the metal into fine equiaxed grains, eliminate deformation hardening, and restore the plasticity and deformation ability of the metal or alloy.

Summary:

These annealing processes have their own characteristics and are suitable for different metal materials and working conditions. Selecting a suitable annealing process is crucial to improving the performance of metal materials and extending their service life.

4.Application of annealing process

(1) Mechanical manufacturing industry:

In mechanical manufacturing, annealing is usually used as a preliminary heat treatment process to improve the cutting performance of the workpiece and reduce the tendency of deformation and cracking during subsequent processing.

(2) Tool steel processing:

Tool steel usually needs to be spheroidized annealed before quenching to reduce hardness, improve cutting performance, and prepare for subsequent quenching.

(3) Welding part processing:

Welding parts will produce large internal stress after welding. Stress relief annealing can effectively eliminate these internal stresses and improve the dimensional stability and service life of welded parts.

(4) Casting and forging processing:

Castings and forgings will produce uneven structure and residual stress during the forming process. These defects can be improved by complete annealing or diffusion annealing, thereby improving the comprehensive performance of the workpiece.

5.Why do castings need to be annealed?

(1) Eliminate internal stress:

During the casting process, castings will produce internal stress due to uneven cooling and phase change. These internal stresses may cause the casting to deform or crack during subsequent processing or use. Through annealing, these internal stresses can be eliminated or reduced, improving the dimensional stability of the casting and reducing the tendency to deform.

(2) Improve machinability:

After annealing, the hardness of the casting will decrease and the plasticity will increase, thereby improving the machinability and making subsequent mechanical processing easier.

(3) Grain refinement:

The annealing process can refine the grain of the casting and improve the structure, thereby improving the mechanical properties of the casting, such as strength and toughness.

(4) Stabilize the size:

Through annealing, the size of the casting can be stabilized and the dimensional changes caused by internal stress can be reduced, which is particularly important for precision castings.

(5) Prepare for the final heat treatment:

Annealing can also prepare the structure for the final heat treatment of the casting (such as quenching and tempering) to ensure that the casting obtains the required final properties.

6.Conclusion

As an important metal heat treatment method, the annealing process is widely used in industrial production. By rationally selecting annealing process parameters, the mechanical properties of metal materials can be effectively improved, and the service life and reliability of workpieces can be increased.