CNC Milling

BENEFITS

CNC programs control cutting tool trajectories with microscopic precision, using servo motors and encoders to achieve micron-level positioning tolerances. This eliminates the human errors inherent in manual machining, so parts always meet the required specifications.

FEATURES

The inherent rigidity of CNC machine tool structures minimizes deflection and vibration during machining, further improving accuracy and repeatability. This means improved dimensional accuracy, improved surface finish, and enhanced functionality of the finished part.

BENEFITS

Automatic tool changers and rotary systems enable fast switching between different cutting tools, eliminating the need for manual tool changes and minimizing machine downtime. This significantly shortens production cycles compared to traditional processing methods.

FEATURES

CNC programs optimize tool path planning and machining parameters to ensure efficient material removal and minimize non-cutting time. This further increases production throughput and yield.

The multi-axis capabilities of CNC machines allow complex features on multiple workpiece surfaces to be machined simultaneously, eliminating the need for multiple setups and further increasing efficiency.

BENEFITS

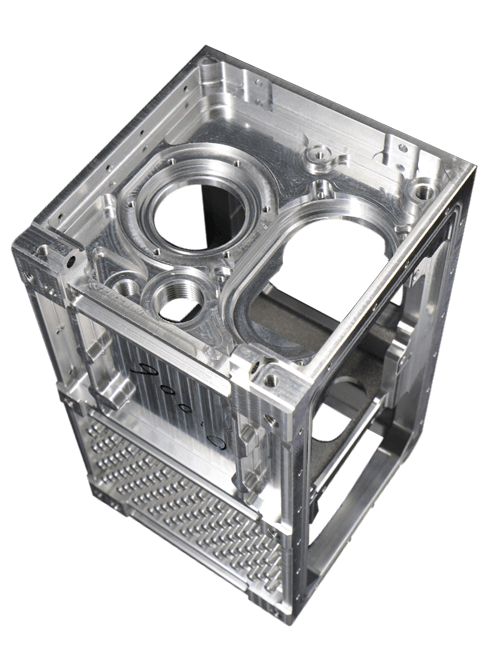

Unlike traditional machining methods that are limited to linear and rotary motion, the multi-axis capabilities of CNC machines make it easy to create complex and unconventional shapes. This opens the door to innovative product design, allowing the integration of complex features to enhance functionality, aesthetics, and weight optimization.

FEATURES

CNC programming software offers advanced capabilities such as 5-axis machining and contour milling, enabling the creation of free-form surfaces and complex geometric details with excellent accuracy and surface finish.

Applications & Grades

CNC milling offers numerous advantages, making it a powerful choice for a variety of manufacturing applications by using computer-controlled cutting tools to remove material from a workpiece to achieve predefined dimensions and geometries.

- Turbine Blades & Wing Components

- Precision satellite components

- Engine Block & Cylinder Head

- Transmission Gears & Synchronizers