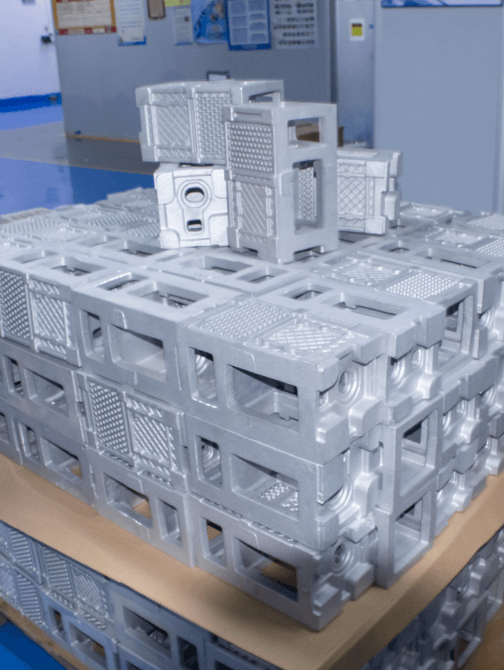

Gravity casting

BENEFITS

Gravity casting is a versatile and reliable process that offers many advantages over other methods. It is ideal for the production of small and medium-sized parts with complex geometries and high quality requirements.

FEATURES

And because there is no external pressure during the casting process, the process produces parts with excellent dimensional accuracy and extremely close tolerances.

BENEFITS

Unlike die casting, gravity casting utilizes gravity to fill the mold cavity, while pressure die casting utilizes high pressure. Molten metal is poured from a ladle into the mold. Die casting is typically used to produce large quantities of parts quickly and efficiently; gravity casting is better suited for smaller batches.

FEATURES

Generally better suited for producing parts with greater dimensional accuracy and surface finish. The process can produce parts with complex geometries and thin walls, making it ideal for a wide range of applications across a variety of industries.

BENEFITS

Gravity casting is often used to produce small and medium-sized parts with complex shapes, such as engine parts, cavity parts, pump parts and gears.

FEATURES

Casting parts generally have excellent mechanical properties, such as high durability and high strength.

Applications & Grades

Gravity casting is a fast and economical casting process. It has high repetition accuracy, long service life and low mold cost. It also has good mechanical properties, high degree of automation and high productivity.

- Engine variable speed box parts

- Engine Components

- Pump Parts & Gears

- Transformer cavity