Die Casting Parts

BENEFITS

The machine has high productivity. For example, the domestic JIII3 horizontal cold air die casting machine can die cast 600-700 times on average, and the small hot chamber die casting machine can die cast 3000-7000 times every eight hours. The die casting mold has a long service life, and the die casting mold. The die casting alloy with a life of hundreds of thousands or even millions of times; it is easy to mechanize and automate.

FEATURES

Because die castings often have a smooth surface and excellent mechanical properties, die castings often require less machining. In some cases, no machining is required at all. As a result, less is spent on secondary operations. Die casting’s ability to reduce post-processing costs helps ensure it is cost-effective.

BENEFITS

The casting has high dimensional accuracy, generally equivalent to 6~7, or even up to 4;

Good surface finish, generally equivalent to 5~8;

High strength and hardness, generally 25~30% higher than sand casting, but the expansion rate is reduced by about 70%;

Dimensionally stable and good interchangeability;

Thin-walled complex castings can be die-cast. For example, the minimum wall thickness of the current zinc alloy die-casting is 0.3 mm; aluminum alloy castings are up to 0.5 mm; the minimum casting hole diameter is 0.7 mm, and the minimum spacing is 0.75 mm.

FEATURES

Die casting products have excellent mechanical properties. When liquid metal solidifies under high pressure, the product looks delicate, dense and crystalline. Die castings have high hardness and strength. In addition, they also have improved durability and high conductivity.

BENEFITS

Because die castings are accurate in size and have a smooth surface. Generally speaking, they are no longer used directly after mechanical processing, or the processing volume is small, thereby improving the utilization rate of metals and reducing a large amount of processing equipment and man-hours; the price of castings is easy; combined die casting can be used for other metals or non-metallic materials. . Save assembly time and save metal.

FEATURES

Because die castings often have a smooth surface and excellent mechanical properties, die castings often require less machining. In some cases, no machining is required at all. As a result, less is spent on secondary operations. Die casting’s ability to reduce post-processing costs helps ensure it is cost-effective.

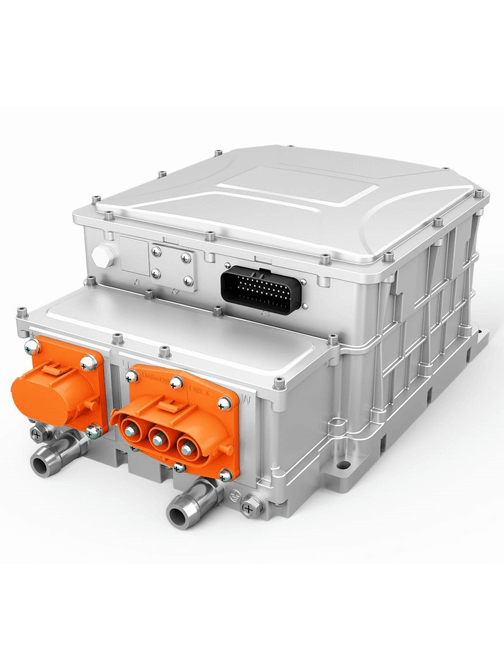

Applications & Grades

Die cast parts are ideal for rapid and large-scale production and can be manufactured into complex but precise shapes. Die cast parts tend to be very strong so they can withstand high pressure injection. Because they hold tight tolerances, they are also heat resistant and dimensionally stable.

- Pumps & Valves

- Cylinder head & engine block

- Clutch Brake & Piston Housing

- Cam cover & Connector housing