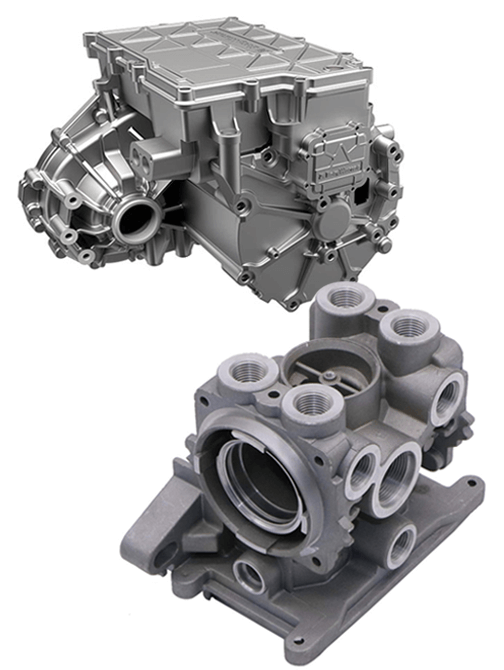

Casting parts

BENEFITS

For both large and small batch production, metal castings offer a more cost-effective option due to their speed, long tool life, and ease of achieving complex geometries.

FEATURES

Since metal castings are poured, minimal tooling is required. Parts can be produced quickly and in small or large quantities, making it perfect for low-volume manufacturing.

BENEFITS

Metal castings are an excellent choice for complex parts because they allow for design flexibility, as castings are available in a variety of sizes and shapes. Another advantage is that you can easily achieve hollow sections or internal cavities.

FEATURES

Castings can be very small or very large without compromising quality or structure. Even the most complex parts can be metal cast, which is more time-saving and cost-effective than machining.

BENEFITS

Metal castings have high compressive strength, high durability, high strength, are suitable for heat-treated parts, and can be produced with thin walls without losing structural integrity.

FEATURES

Casting is a manufacturing process in which a material, usually liquid, is poured into a mold containing a cavity of the desired shape and then allowed to solidify. The solidified part, also called a casting, is ejected or broken from the mold to complete the process.

Applications & Grades

Whether it’s renewable energy or rugged robotics, castings are used in more areas than ever before. We supply high-precision industrial castings for a wide range of industries and applications

- Gearbox & Guide Rail Base

- Robot arms, housings, axes, etc.

- Turbine housing & gear assembly

- Brackets, Housings, Joint parts