Metallic Glass Copper Mold Casting – Process Analysis and Application Prospects

Metallic glass copper mold casting is a method for rapidly cooling molten alloys and forming an amorphous structure by utilizing the high thermal conductivity of copper molds. Its simplicity and remarkable results make it an important approach for the research and application of metallic glass. This article will focus on the process principles, procedures, characteristics, and applications.

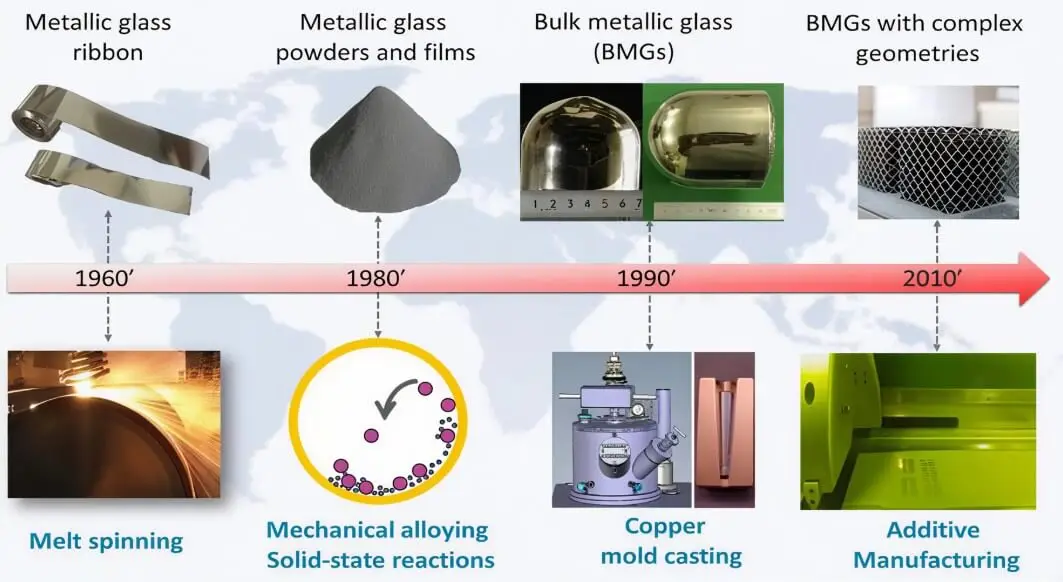

1.Development and Process of Metallic Glass

1960s: Metallic Glass Ribbons

Researchers first used the melt quenching method to spray molten alloy onto a rapidly rotating cooling wheel, suppressing crystal formation at a cooling rate of approximately 10⁵–10⁶ K/s. This method produced amorphous metallic glass ribbons, marking the birth of metallic glass.

1980s: Metallic Glass Powders and Thin Films

To expand applications, researchers utilized mechanical alloying and solid-state reactions, achieving amorphous structures in the solid state through methods such as high-energy ball milling, and achieved the production of metallic glass powders and thin films.

1990s: Bulk Metallic Glass

Researchers used copper mold casting, leveraging copper’s high thermal conductivity to rapidly cool molten alloys, to successfully produce centimeter-thick bulk metallic glass. This breakthrough, surpassing the previous limitations of only being able to produce thin ribbons or powders, marked a milestone in the field.

Since the 2010s: Exploration of Complex Geometric Structures

With advances in manufacturing technology, research has gradually introduced additive manufacturing, such as selective laser melting (SLM) and electron beam melting (EBM), to attempt to form metallic glass components with complex geometries.

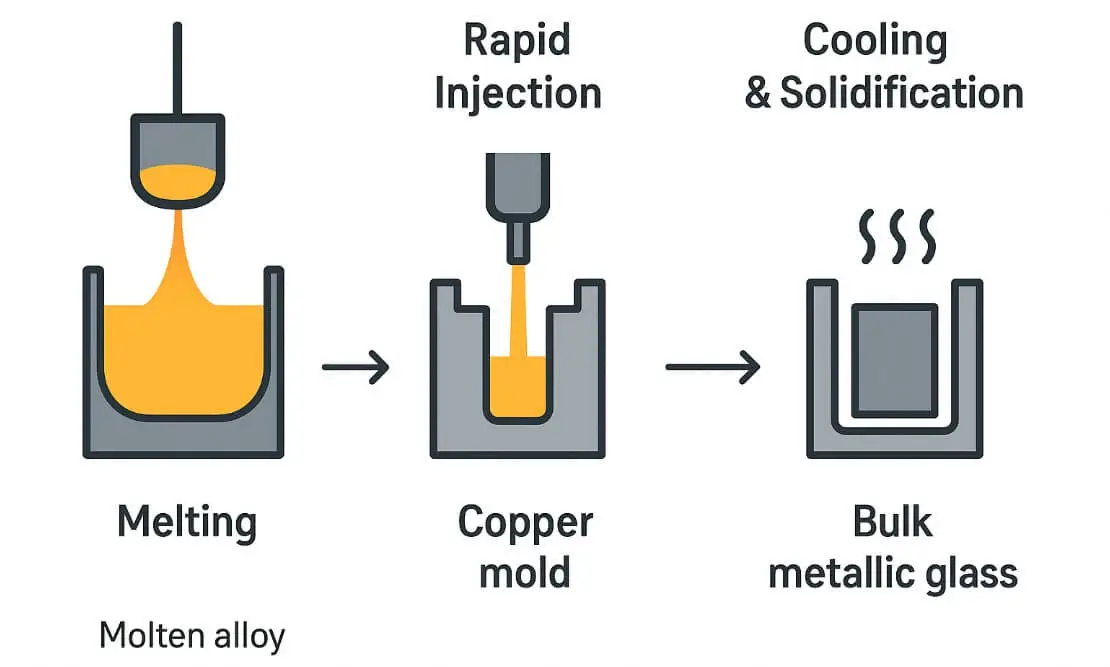

2.What is Metal Glass Copper Mold Casting?

Copper mold casting of metallic glass is a process used to produce “metallic glass” (also known as bulk amorphous alloy). The principle is to rapidly pour the molten alloy into a copper mold with a high cooling rate, allowing the metal to solidify in an extremely short time. This avoids the formation of a typical crystalline structure and instead produces a disordered “amorphous” structure. The resulting material exhibits high strength, hardness, and excellent corrosion resistance.

3.Why use copper molds to cast metallic glass?

Copper has excellent thermal conductivity. The moment the molten metal contacts the copper mold, it quickly dissipates heat, achieving the required high cooling rate. This rapid cooling is crucial for the formation of metallic glass. If the cooling is not rapid enough, crystallization will occur, resulting in the loss of its “glassy” properties.

4.How large can metallic glass products be produced using copper mold casting?

Forming size is a key research focus. For example:

Research has shown that by optimizing the alloy composition and process, metallic glass rods with a diameter of 73 mm can be produced (AIP report).

For certain compositions, such as Cu-Zr-Al-Ag alloys, bulk metallic glass with a diameter of 25 mm has been successfully produced using the copper mold casting process.

Generally speaking, larger diameters require higher cooling rates and are more difficult to form.

5.Detailed explanation of the process flow of metallic glass copper mold casting

The entire process can be divided into three main stages: melting, rapid pouring, and cooling and solidification.

(1) First is the melting stage

High-purity alloy materials need to be heated in an induction or arc furnace until they are completely melted. During this process, the melt must be fully mixed to ensure uniform composition, otherwise local deviations will affect the amorphization ability.

At the same time, melting is usually carried out under vacuum or inert atmosphere to reduce oxidation and pores. Temperature control is also very critical. It should not be too low to cause poor pouring, nor too high to increase the risk of oxidation. It is usually controlled within the range of ±5–10°C.

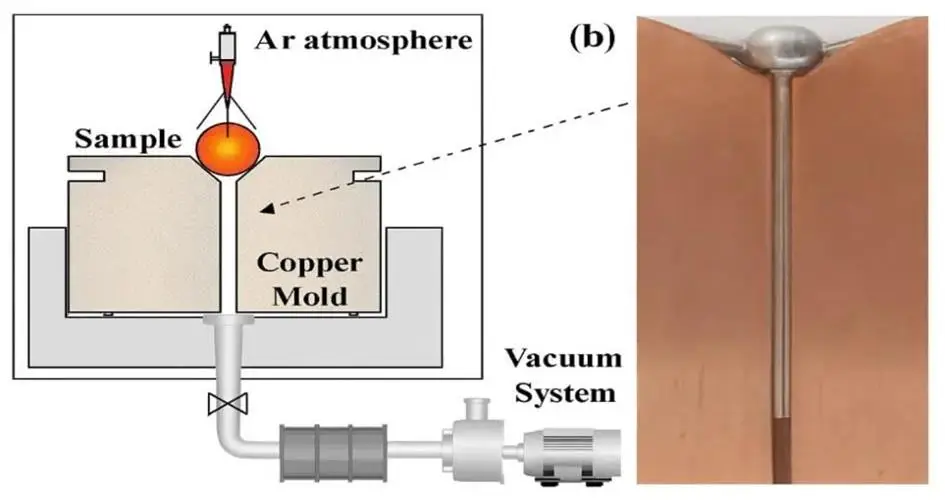

(2) Next is the rapid pouring stage

The molten metal must be injected into the copper mold cavity as quickly as possible to achieve a sufficiently high cooling rate. The faster the injection speed, the shorter the contact time between the metal and the copper mold, the better the cooling effect, and the better it is to inhibit crystal formation. The entire process is usually carried out in an inert gas or vacuum environment to avoid oxidation. At the same time, the copper mold may need to be preheated or coated with an isolation layer to regulate heat exchange and avoid surface overcooling that causes crystal formation.

(3) Finally, the cooling and solidification stage

The high thermal conductivity of the copper mold itself can cool the melt in a very short time to form an amorphous structure. During this stage, uniform cooling rates are crucial. If the central area cools too slowly, crystals can easily form, affecting material properties.

Therefore, mold design, cavity thickness, and injection method all require careful optimization. For certain large or complex-shaped castings, a light annealing treatment may be performed after cooling to relieve internal stresses while maintaining the stability of the amorphous structure.

6.What defects can occur in metallic glass during copper mold casting?

Common problems are surface crystallization and localized crystallization.

Surface crystallization: Even at high cooling rates, heterogeneous nucleation can occur on the mold surface, leading to crystal precipitation at the edges.

Localized crystallization: Large differences in cooling rates in different areas of the copper mold, such as in the corners or center of the mold, can cause tiny grains to form, affecting the overall amorphous ratio.

These problems can degrade material properties, necessitating strict control of pouring temperature, mold design, and cooling conditions.

7.What are the significant properties of metallic glass produced through copper mold casting?

Ultra-high strength and hardness: Far superior to those of ordinary crystalline alloys.

Good corrosion resistance: Amorphous structure reduces the corrosion pathway.

Processing characteristics: Suitable for small, high-precision structural parts, but the manufacturing of large-size parts is still limited.

Structural uniformity: Under the condition of successfully avoiding crystallization, the internal structure is very uniform, which is very valuable in aerospace, medical, precision instruments and other fields.

8.Application direction of metallic glass copper mold casting

(1) Electronics and power systems

Metallic glass has excellent soft magnetic properties (low coercivity, high magnetic permeability, low loss), so it can be used in power system components such as transformer cores, inductors, and motors.

Theoretical basis: Inoue (2000) pointed out that there are no grain boundaries and dislocations in the amorphous structure, and the resistance when the magnetic domain wall moves is smaller, thereby achieving low energy loss.

Reference: Inoue A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Materialia, 2000.

(2) Medical devices and biomaterials

Some Zr-based and Ti-based metallic glasses exhibit excellent corrosion resistance and good biocompatibility, and are suitable for the preparation of surgical blades, orthopedic fixation parts and dental tools.

Theoretical basis: Greer (1995) pointed out that the surface structure of amorphous alloys is uniform and dense, and there is a lack of intergranular corrosion sensitive areas, so its corrosion resistance is better than that of traditional metals such as stainless steel.

Reference: Greer A.L. Metallic glasses. Science, 1995.

(3) Aerospace and defense

Metallic glasses have extremely high strength and elastic limit (yield strength can reach 2 GPa, elastic strain exceeds 2%), and are ideal lightweight and high-strength materials. They can be used in spacecraft structural parts, protective components and high-precision elastic components.

Theoretical basis: Wang (2004) showed that the strength of amorphous alloys is close to the theoretical limit of atomic bonding, which is a property that crystalline alloys cannot achieve.

Reference: Wang W.H. Bulk metallic glasses with functional physical properties. Advanced Materials, 2004.

(4) Consumer electronics and decoration fields

Metallic glass has high hardness (500–600 HV), scratch resistance and unique metallic luster, and can be used in mobile phone cases, watch straps, and luxury decorative parts.

Theoretical basis: Johnson (1999) pointed out that metallic glass can maintain its wear resistance without additional coating, and its optical reflective properties and structural density make it have high-end decorative value.

References: Johnson W.L. Bulk glass-forming metallic alloys: Science and technology. MRS Bulletin, 1999.

(5) Micro-nano manufacturing and mold applications

In the supercooled liquid region (between Tg and Tx), metallic glass exhibits viscous flow similar to that of thermoplastic polymers and can be used in microgears, microfluidic chips, and optical microstructure molds.

Theoretical basis: Johnson (1999) pointed out that the viscosity of metallic glass drops to 10^6 Pa·s at 0.6–0.7 Tg, making it suitable for thermoplastic forming. This unique thermoplastic processing capability enables it to replace silicon or polymer molds.

References: Johnson W.L. Bulk glass-forming metallic alloys: Science and technology. MRS Bulletin, 1999.

9.Summary

Metallic glass copper mold casting provides an effective means for the research and application of amorphous alloys. With its unique properties and broad prospects, this process is driving metallic glass into more high-end manufacturing fields.

LVXUN’s Metal Casting Services

Beyond metal glass copper mold casting, casting processes are widely used in industrial production. LVXUN specializes in a variety of metal casting services, including die casting, low pressure casting, gravity casting, and investment casting, meeting the production needs of parts with diverse materials and structures. Leveraging advanced equipment and extensive processing experience, we provide clients with one-stop casting solutions, from design to finished product. If you have metal casting needs, you can upload part drawings online at any time to receive professional quotes and customized solutions.

FAQs:

What materials are suitable for copper mold casting of metallic glass?

This process is primarily suitable for metallic glass materials. Common metallic glasses include:

Aluminum-based metallic glass

Titanium-based metallic glass

Cobalt-based metallic glass

Magnesium-based metallic glass

These materials have excellent mechanical properties and corrosion resistance and are widely used in specialized applications.

Is there a difference between copper mold casting and other processes such as die casting, low pressure casting, gravity casting, and investment casting? What are the differences?

Although they all fall under the broad category of casting processes, they differ significantly in their principles, process conditions, applicable materials, and part performance.

Copper mold casting: Molten metal is rapidly poured into a copper mold, resulting in rapid cooling and high precision. It is suitable for small, simple metallic glass parts.

Die casting: High-pressure casting is performed through a steel mold, offering high efficiency and precision. It is suitable for mass production of low-melting-point metal parts.

Low pressure casting: Low-pressure casting is performed through a metal mold, resulting in stable metal flow and minimal porosity. It is suitable for medium-sized structural parts.

Gravity casting: Relying on gravity for natural cooling, it offers a simple process and low cost. It is suitable for large or simple parts.

Investment casting: Using a wax pattern to create a mold, it offers high precision and can produce complex, thin-walled parts, but it is expensive.

What do you think?

[…] a new type of material, bulk metallic glass has many unique properties, such as high strength, high hardness, excellent elastic limit and good […]

[…] Bulk metallic glass (BMG), also known as amorphous alloy, is a new type of material with unique structure and excellent properties. Let’s talk about the key technologies and advantages of amorphous alloys mentioned above. […]

[…] article will delve into the definition and importance of glass casting, principles and processes, special glass casting technology, advanced glass casting technology, […]

[…] Copper mold casting is a technology that uses molds made of copper alloys for metal casting. Due to its excellent thermal conductivity, the copper mold can quickly absorb and dissipate the heat of the molten metal during the casting process, thereby achieving rapid cooling. This rapid cooling feature enables the casting to obtain a high surface finish and fine microstructure. The main characteristics of copper mold casting include: […]

[…] manufacturing and processing of aluminum metal casting molds is a complex and delicate process, which requires strict control of the quality of each link. […]