Is heat treating the same as baking metal?

Heat treating and baking metal are often confused when we discuss metalworking processes. Is heat treating the same as baking metal? On the surface, they both improve material properties by heating metal, but in fact they are essentially different. This article will provide an in-depth analysis of the differences between heat treatment and baking metal to help everyone understand these two processes more clearly.

1.Is heat treating the same as baking metal: basic conceptual distinctions

Heat treatment and baking are two common processes in material processing, especially for metal materials. Although these two methods look similar on the surface, they actually have significant differences in application purpose, process and final effect.

Heat treatment is a technology that changes material properties by precisely controlling heating, holding and cooling processes. It is widely used in the strengthening and optimization of metal materials. Baking usually refers to heating materials at a relatively low temperature. It is mainly used to remove moisture, grease or other impurities on the surface of the material. Sometimes it is also used for the preliminary heating treatment of the material to prepare for subsequent processing or heat treatment. .

2.Is heat treating the same as baking metal: Detailed explanation of heat treatment technology

(1) Definition

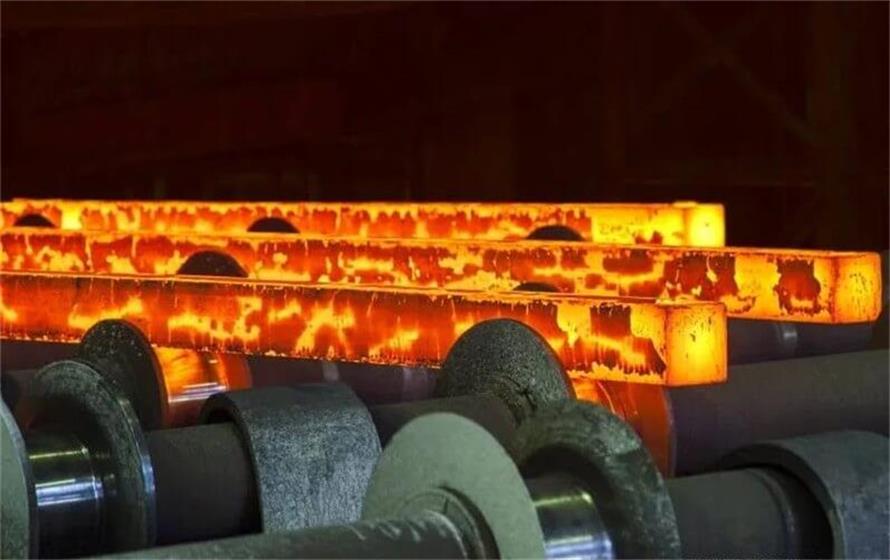

Heat treatment is a process that changes the internal structure and properties of materials by controlling the heating, holding and cooling processes. This technology is mainly applied to metal materials to improve the material’s mechanical properties such as hardness, toughness, wear resistance and fatigue resistance. Heat treatment not only affects the surface properties of the material, but also deeply changes its internal microstructure, thus greatly improving the material’s performance and service life.

(2) Main methods

Common heat treatment methods include annealing, normalizing, quenching and tempering. Annealing is to reduce the hardness and improve the plasticity by heating the metal material to a certain temperature and cooling it slowly;

Normalizing is to heat the material above the critical temperature and then cool it in the air to adjust the grain structure and mechanical properties of the material; quenching is to rapidly cool the material to increase hardness and strength, while tempering is to reduce the quenching process The internal stress generated in the material improves toughness.

Each method has its specific application scenarios and technical requirements. For example, annealing is mainly used to improve the cutting performance of the material, normalizing is mainly used to improve the comprehensive mechanical properties of the material, and quenching and tempering are mainly used to improve the material’s mechanical properties. Hardness and wear resistance.

(3) Application of heat treatment in metal materials

In fields such as machinery manufacturing, aerospace, and automobile industries, heat treatment technology is a key process to improve the performance of metal materials. Through proper heat treatment, the strength, hardness and wear resistance of the material can be significantly improved and the service life of the parts can be extended. For example, when manufacturing high-speed bearings, heat treatment can significantly improve their hardness and wear resistance, thereby ensuring their stability and long life under high stress conditions.

3.Is heat treating the same as baking metal: Detailed analysis of baking technology

(1) Definition

Baking is usually used for preliminary heating of materials in preparation for subsequent processing or heat treatment. The baking process is usually carried out in an oven or other specialized equipment, where temperature and time can be precisely controlled to ensure that the material is not damaged during handling.

(2) Application of baking technology in industry

In the electronics industry, baking is used to remove moisture from circuit boards and prevent electrical shorts. In the food industry, baking is used for the drying and ripening of food, such as bread, cakes, etc. In the chemical and pharmaceutical industries, baking is used to dry raw materials and finished products, ensuring product stability and effectiveness. The application of the baking process is very wide, covering almost all scenarios that require the removal of moisture from the surface of materials or preliminary heating treatment.

(3) Baking treatment of metal materials

In metal processing, baking is often used as a pre-treatment step, such as removing oil and moisture from a surface in preparation for welding, painting or other surface treatments. In addition, some metal materials also need to be baked before heat treatment to remove internal hydrogen and prevent hydrogen embrittlement during subsequent high-temperature treatment. Although baking seems simple, it plays a vital role in the entire processing process of metal materials.

4.Is heat treating the same as baking metal: detailed difference comparison

(1) Process purpose and scope of application

The main purpose of heat treatment is to improve the mechanical properties of materials, such as hardness, strength and toughness, and is suitable for occasions requiring high-performance materials, such as mechanical parts, cutting tools, etc. Baking is mainly used to remove impurities on the surface of materials or perform preliminary heating treatment, and is suitable for electronics, food, chemical industry and other fields. The differences in process purposes and application scope between heat treatment and baking make them play different roles in industrial production.

(2) Temperature control and effects

Heat treatment is usually performed at higher temperatures with very precise temperature control to achieve specific structural changes and performance improvements. Baking is performed at a relatively low temperature, focusing mainly on the surface treatment effect of the material. The temperature control of heat treatment usually needs to be accurate to a few degrees or even a few degrees Celsius, while the temperature control of baking is relatively loose, usually within the range of tens of degrees Celsius.

(3) Changes in material properties

Heat treatment causes significant changes in the internal structure of the material, thereby affecting its mechanical properties such as hardness and toughness. Baking generally does not change the internal structure of the material, but mainly affects the surface state of the material. Heat treatment can achieve fine adjustment of the internal structure of the material by controlling the heating and cooling speed, while baking is mainly used for cleaning and preliminary heating treatment of the material surface.

5.Summary

All that said, is heat treating the same as baking metal? Although heat treating and baking metal are similar in some steps, their purpose, process control and application scenarios are completely different. Heat treatment significantly changes the mechanical properties of the metal through precise control of the heating, holding and cooling processes, while baking the metal is mainly used to remove surface moisture and initially solidify the surface coating. The correct understanding and application of these two processes is crucial to improving the quality and performance of metal products.

What do you think?

[…] 6061-T6 heat-treated process is an important method to improve the strength and hardness of its aluminum alloy. It […]

[…] is the difference between annealed and heat treated? Annealing and heat treatment are two metal processing processes commonly used to improve the […]

[…] is an important heat treatment process that can change the microstructure and mechanical properties of metal materials through […]

[…] is a metal heat treatment process that changes the metal’s microstructure by heating it to a certain temperature and […]

[…] the metal heat treatment process, annealing vs tempering are two crucial links. They optimize the microstructure and […]

[…] strengthening is a method of enhancing the properties of metallic materials through heat treatment, especially for age-hardenable alloys. This thermally strengthen metal method typically involves […]