Is cast aluminum safe? Explore its reliability and risks

As a common industrial material and production process, cast aluminum is widely used in construction, automobile manufacturing, and electronic products due to its excellent thermal conductivity, strength, and lightness. However, with the expansion of its scope of use, more and more people have begun to pay attention to the safety of cast aluminum, that is, is cast aluminum safe? This article will explore and answer in detail the question “Is cast aluminum safe?” and analyze the potential risks and control measures during its use and casting process.

From daily household items to high-tech products, casting aluminum is indispensable. However, is cast aluminum safe? The public’s understanding of this issue is relatively vague. The following will specifically analyze the reliability of cast aluminum in different scenarios and its possible risks.

1.Is cast aluminum safe? Product safety analysis

Cast aluminum products are widely used in many fields due to their excellent durability, light weight, and rust resistance. So, is cast aluminum safe? Under normal use conditions, cast aluminum products are safe and reliable. For example, outdoor cast aluminum tables and chairs have the advantages of beauty, durability, and corrosion resistance, and are suitable for various environments.

However, cast aluminum products also have some potential risks. First, during the aluminum casting process, the gas produced when aluminum dissolves at high temperatures may be harmful to the human body, so operators need to wear protective masks. Secondly, cast aluminum products are afraid of acid and alkali corrosion, and long-term contact with acid and alkali substances may cause product damage. In addition, some inferior cast aluminum products on the market may contain impurities and their safety performance cannot be guaranteed.

Summary:

Is cast aluminum safe? The answer to this question is that it is relatively safe under normal use. In order to ensure the safety of cast aluminum products, consumers should choose qualified products produced by regular manufacturers and avoid buying inferior products. At the same time, during use, pay attention to avoid contact with acid and alkali substances to extend the service life of the product.

2.Is cast aluminum cookware safe?

Cast aluminum cookware is relatively safe under normal use, but there are still some potential risks. The following is a detailed analysis of its reliability and risks:

(1) Reliability

1) Cast aluminum cookware has the characteristics of lightness, fast heat conduction, and uniform heating, and is widely used in households and the catering industry.

2) A dense aluminum oxide film is usually formed on the surface of cast aluminum cookware. This film can prevent aluminum precipitation to a certain extent and improve the safety of the cookware.

(2) Possible risks

1) Aluminum precipitation: In some cases, such as cooking with acidic or alkaline foods, storing food for a long time, etc., aluminum may precipitate from the cookware and enter the human body. Long-term and large-scale intake of aluminum may have adverse effects on the nervous system, immune system, etc., and may even cause neurodegenerative diseases such as Alzheimer’s disease.

2) Coating problems: Some cast aluminum cookware has a non-stick coating on the surface. If the coating is damaged, aluminum may be more likely to precipitate. In addition, the non-stick coating itself may also release harmful substances at high temperatures.

Summary:

Cast aluminum cookware is relatively safe under normal use, but during use, care should be taken to avoid cooking with acidic or alkaline foods, not storing food for a long time, and preventing the coating from being damaged.

3.Is die-cast aluminum safe?

As a commonly used material, aluminum has been widely used in modern industry. From pots to auto parts, die-cast aluminum products can be seen everywhere in our daily lives. So, is cast aluminum safe?

First of all, aluminum itself is not toxic. Aluminum is a relatively stable metal that does not easily precipitate harmful substances. Even at high temperatures, die-cast aluminum does not release toxic gases. This makes die-cast aluminum widely used in many fields with high safety requirements, such as food processing and medical device manufacturing.

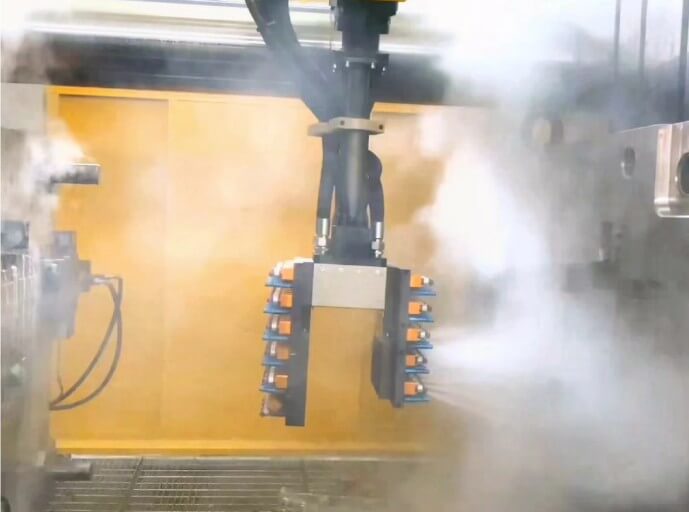

However, there may be some hazards in the production process of die-cast aluminum. Aluminum produces harmful gases during the melting process. If the workshop is poorly ventilated, these gases may cause harm to the human body. In addition, the high-temperature molten metal during the die-casting process may also cause burns. In order to protect the health of workers, strict labor protection measures must be taken during the production process, such as wearing masks and gas masks, and ensuring that the workshop has a good ventilation system.

Summary:

In general, die-cast aluminum materials themselves are safe, but safety protection should be paid attention to during the production process. As long as the manufacturer strictly abides by safety standards, die-cast aluminum products can be used with confidence.

4.Is cast aluminum safe? Casting process safety analysis

There are many safety risks in the production process of cast aluminum, mainly including:

(1) Explosion and burns:

High-temperature aluminum liquid will explode when it comes into contact with water, accompanied by aluminum liquid explosion and overflow, which may cause serious burns, death and fire accidents.

(2) Mechanical injuries:

During the maintenance and production process, especially the production of aluminum alloy round ingots and flat ingots, there are hidden dangers of safety accidents such as collision, squeezing, and smashing due to the large number of intermediate products, long production lines, frequent lifting work, and a large number of cross-operations of overhead cranes, forklifts, and on-site sawing equipment.

(3) Burns and scalds:

During the casting process, there are some high-temperature equipment, media or objects that are easy to cause scalding accidents, such as high-temperature vacuum ladle, gas burner ignition caused by loose closure of the melting furnace door, and waste stored on site that is not fully cooled.

(4) Toxic gases:

Chlorine or other toxic gases are sometimes used for refining in melting and casting. If these gases leak or do not react completely, they will cause great harm to people.

(5) Oxygen-deficient environment:

In low-lying areas, if inert gas leaks and accumulates, it is easy to cause an oxygen-deficient environment, which will cause the danger of oxygen deficiency to people.

(6) Metal dust:

In some environments where there is a large amount of aluminum alloy dust, high concentrations of aluminum alloy dust may explode when exposed to open flames.

(7) Failure of the cooling system:

During the crystallization process, if the crystallizer is not sealed tightly or the cooling system fails, aluminum liquid may leak. After direct contact with cooling water or air, it may cause thermal stress, abnormal chemical reactions, or even instantaneous expansion of the gas, leading to explosion.

(8) Improper equipment maintenance:

Improper equipment maintenance, operating errors or design defects may all be the fuse that leads to accidents.

5.Is cast aluminum safe? Analysis of casting process control measures

In order to ensure the safety of the aluminum casting process, a series of risk control measures need to be taken to reduce potential safety risks. The following are some key control measures:

(1) Strengthen employee training:

Provide regular safety training, including training on fire escape, chemical handling, mechanical equipment operation, etc., to improve employees’ risk awareness and response capabilities.

(2) Safety equipment equipment:

Provide appropriate personal protective equipment, such as protective glasses and protective clothing, to protect employees from physical and chemical risks.

(3) Safety operating procedures:

Establish and implement strict safety operating procedures, including furnace operation, chemical use, mechanical equipment operation, etc., to reduce the occurrence of operating errors and accidents.

(4) Regular inspection and maintenance of equipment:

Regularly inspect and maintain mechanical equipment to ensure its normal operation and reduce the risk of mechanical failure and injury.

(5) Fire-fighting equipment and emergency plans:

Equip with sufficient fire extinguishers, fire-fighting equipment and emergency plans, and conduct regular drills to improve the ability to deal with fires.

(6) Optimize process layout:

Set up a separate casting workshop or take hard isolation measures such as explosion-proof walls in the casting area, strengthen source control, and ensure that the procurement of production equipment is of qualified quality and meets safety conditions.

(7) Key parameter monitoring:

Strengthen the monitoring and control of key parameters such as cooling water flow and temperature, casting speed, and aluminum liquid temperature, and reasonably set up emergency water sources to ensure that the requirements of emergency water pressure, flow and time are met.

6.Summary

Is cast aluminum safe? Through the comprehensive analysis of this article, this question has been answered. In short, aluminum casting is a relatively safe material with broad application prospects under the conditions of reasonable production and correct use of aluminum casting products. Through strict quality control and continuous technological innovation, we can further improve the safety of aluminum casting and promote its sustainable development in various fields.