Understand the Core Knowledge of Extrusion Dies in One Article

In modern manufacturing, the widespread use of aluminum profiles and plastic sheets is inseparable from the extrusion process. As one of the most critical pieces of equipment, the extrusion die determines the material’s molding precision, surface quality, and production efficiency. This article systematically introduces the working principle, structure, types, manufacturing process, lifespan, and design key points of the extrusion die to help readers fully understand this critical process.

Table of Contents

1.What is the Extrusion Process?

In the manufacturing of plastic and metal products, various molding methods have gradually developed, depending on the material properties and product shape, such as injection molding, blow molding, casting, and extrusion.

Among them, extrusion is a widely used process for the production of continuous profiles, particularly suitable for manufacturing products with fixed cross-sections and variable lengths, such as plastic pipes, cable sheathing, aluminum profiles, and building structures.

Extrusion involves heating or pre-treating a plastic material (such as metal or plastic) and then forcing it under high pressure through a die with an opening of a specific cross-sectional shape. The material flows out along the die channel, resulting in a continuous profile with that cross-sectional shape. This process can be used for solid, hollow, or profiles with complex internal structures, and is suitable for both hot and cold extrusion.

2.What is an Extrusion Die?

An extrusion die is the tool used to give the material its shape during the extrusion process: typically a thick steel plate or molded part with holes and channels corresponding to the cross-sectional shape of the final product. When the material is pushed through the die opening under high pressure, it flows out in the shape of the die opening. The die’s design, material, heat treatment, and surface condition directly influence the dimensions, precision, wall thickness consistency, and surface quality of the final extruded part.

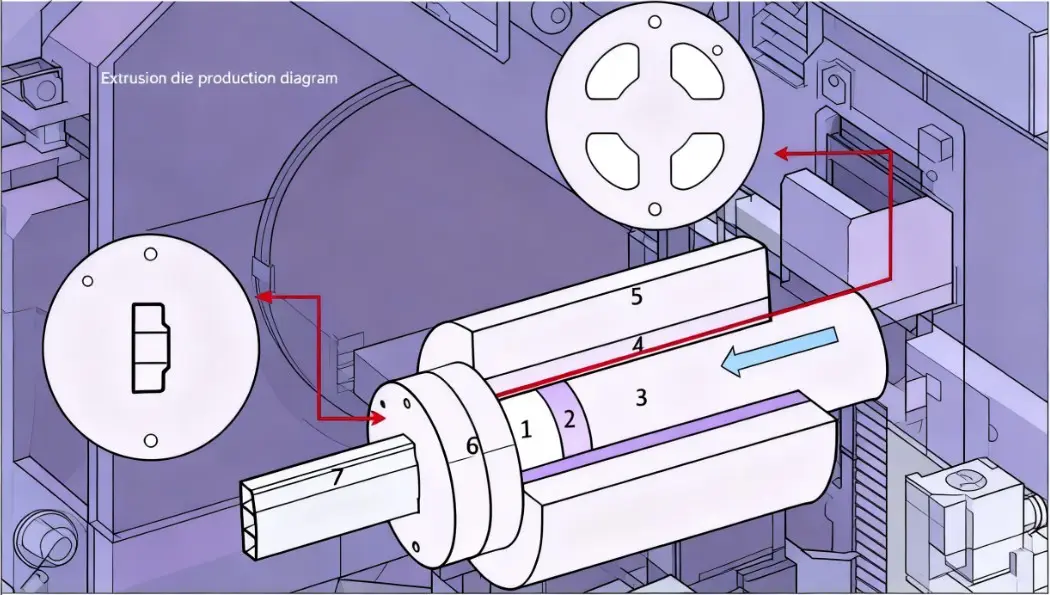

3.Working Principle of an Extrusion Die

The extrusion die process begins when the material enters the die inlet from the extruder’s screw. After being conveyed and plasticized by the screw, the material is continuously fed into the die at a specific temperature and pressure. The die’s runner system evenly distributes the molten material throughout the die cavity, ensuring full expansion and a stable flow rate.

As the material passes through the die opening (lip), its thickness and width are precisely controlled, and the molten material gradually forms a continuous sheet or film. The extruded material then passes through chill rolls or a shaping device to cool and solidify, ultimately resulting in a product with uniform thickness and a smooth surface.

The core tasks of an extrusion die are to guide material flow, control flow velocity distribution, and ensure uniform thickness and dimensional stability. Due to the significant differences in rheological properties between materials, die design requires ensuring uniform material flow across the entire width through measures such as runner geometry, die opening clearance, and temperature control. This is also one of the most technically demanding and challenging aspects of extrusion die design.

4.Extrusion Die Structure

The basic structure of an extrusion die typically consists of three major components: the die body, the width adjustment system, and the thickness adjustment system.

Die Body

The die body is the core structure of the die, housing the runners and bearing the primary mechanical loads. It determines the material flow path and pressure distribution. High-quality tool steel or corrosion-resistant stainless steel is typically used in the manufacture of the die body to ensure excellent thermal conductivity, wear resistance, and dimensional stability.

The die body often undergoes precision CNC machining, grinding, and polishing to ensure a smooth flow path surface, minimizing flow resistance and material retention during extrusion.

Width Adjustment System

The width adjustment system controls the discharge width of sheet or plate. Based on process requirements, the effective width of the die opening can be varied using internal and external width adjustment mechanisms to accommodate varying product specifications. Modern extrusion dies are often equipped with precise and easy-to-operate adjustment mechanisms to enhance production flexibility and repeatability.

Thickness Adjustment System

The thickness adjustment system fine-tunes the discharge opening (die lip) gap, thereby controlling product thickness. Typically, a series of adjustment screws are used to finely adjust the die lip gap to ensure uniform thickness distribution. For products with large thickness variations, a quick gap adjustment system or replaceable die lip assembly can be used to improve adaptability and operational efficiency.

5.Extrusion Die Types

Based on the cross-sectional characteristics of the profile being produced, extrusion dies are primarily divided into three categories: solid, semi-hollow, and hollow.

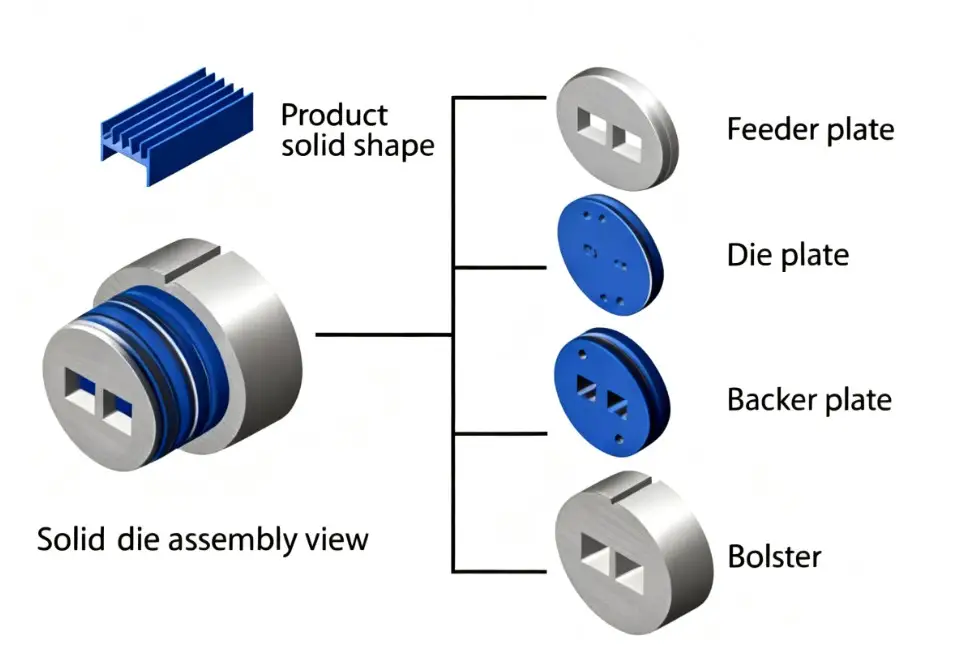

Solid Dies

Solid dies are used to produce profiles without enclosed voids or openings, such as bars, angles, or beams. Solid dies are relatively inexpensive to manufacture. A solid die set typically consists of a feed plate, die plate, and backing plate:

- Feed plate: Controls the direction and uniformity of metal flow into the die orifices.

- Die plate: Forms the final cross-sectional shape of the profile.

- Backing plate: Supports the die plate and die tongue, preventing deformation and transmitting the extrusion load.

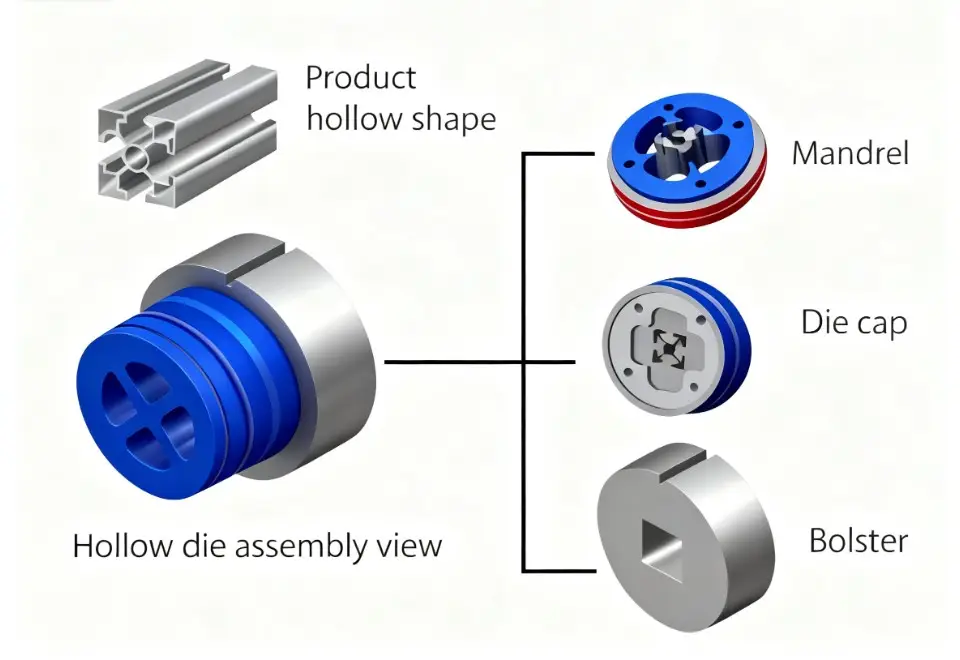

Hollow Dies

Hollow dies are used to produce profiles with one or more internal cavities, such as tubes or complex, porous profiles. Due to their complex structure, their manufacturing cost is higher than that of solid dies. The main components of a hollow die include a mandrel, die cover, and support base:

- Mandrel: Located inside the die, it forms the profile’s internal cavity through multiple discharge holes and controls metal flow. The materials rejoin in the welding chamber before entering the pressure zone, with the discharge port supported by the web.

- Die cover: A multi-piece structure used to shape the profile’s outer shape.

- Support base: Carries the extrusion load transmitted from the die cover and mandrel.

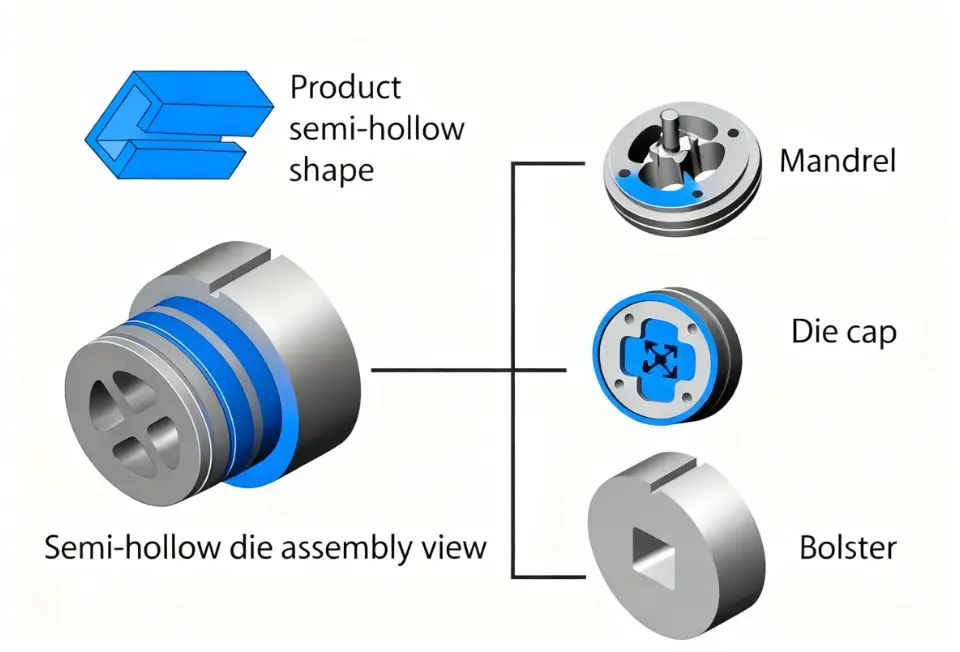

Semi-hollow die

Semi-hollow dies are used to produce partially enclosed profiles. Their cavity area is smaller than that of hollow profiles but larger than that of solid profiles. Their die structure is similar to that of hollow dies, consisting of a perforated mandrel, die cover, and die base.

The complexity of a semi-hollow die is primarily determined by the tongue ratio (the ratio of the gap area between the tongue and the die body to the profile cavity area). A larger tongue ratio increases manufacturing difficulty and cost.

In summary, the three types of dies differ in whether the profile has an internal cavity and the size of the cavity, which in turn influences die structural complexity, material usage, and manufacturing cost.

6.Extrusion Die Design

Effective die design is critical to the aluminum extrusion process, directly impacting quality, efficiency, and cost-effectiveness. The following principles are generally followed during design:

Uniform material flow:

Ensures smooth and uniform material flow, minimizing turbulence, dead zones, and warpage. This is achieved by adjusting bearing length, tooth face length, and the configuration of flow channels and feeders.

Optimal bearing length:

The bearing length should be appropriately designed based on the thickness of the profile to ensure consistent flow velocities across all sections. Longer bearings should be used in thicker areas to reduce velocities and match the flow velocities in thinner areas.

Finite element analysis (FEA):

Use FEA to simulate the extrusion process and analyze die stresses, thermal behavior, and material flow to identify potential problems early.

Thermal management:

Appropriate cooling and heating designs ensure uniform die temperature, avoid defects caused by temperature fluctuations, and ensure product mechanical properties and surface quality.

Surface engineering:

Surface treatments such as nitriding, chrome plating, or hard coatings improve wear resistance and smoothness, extending die life.

Material selection:

Select appropriate die steel, such as H13, which combines thermal conductivity, wear resistance, and toughness, making it suitable for most aluminum extrusion dies.

This design approach enables comprehensive control of flow, thermal, and mechanical properties, ensuring high quality, high efficiency, and long die life.

7.Extrusion Die Manufacturing

The extrusion die manufacturing process includes CNC machining, grinding, polishing, chrome plating, inspection, and assembly. Each step requires appropriate equipment and skilled operators to ensure die quality. These processes are interdependent and closely linked, collectively determining die performance and service life.

In die flow channel design, in addition to the main and secondary flow channels, the section near the outlet is called the “blanking zone.” This area is where the material resides, ultimately being stretched and transformed into a smooth sheet or profile. Therefore, the process design of the blanking zone is crucial. Whether it’s surface grinding, mirror polishing, or chrome plating, each step requires precise calculations. As die width increases, the complexity of the blanking zone process also increases.

8.What is the service life of an extrusion die?

There is no fixed “standard value” for the service life of an extrusion die; it is influenced by a variety of factors, including design, materials, process conditions, and maintenance status. Generally speaking, under ideal conditions, high-quality molds can last tens to hundreds of thousands of extrusion cycles.

Specifically, the following factors significantly affect mold life:

Profile design difficulty: Thin walls, unbalanced shapes, and protruding legs can cause heat buildup and uneven pressure, leading to premature mold failure.

Material and heat treatment: Using high-quality mold steel (such as nitrided or chromized steel) can improve wear resistance and fatigue resistance.

Temperature management and surface condition: Molds in high-temperature environments are subject to thermal expansion, metal structural changes, and oxidation. Poor thermal management can accelerate mold performance degradation.

Operating parameters and maintenance: The quality of operations such as extrusion speed, lubrication, cleaning, and maintenance directly impacts mold life.

Therefore, in actual production, to ensure stability, manufacturers often replace or repair molds before they reach a certain lifespan. Designers should optimize profile geometry and control thermal imbalances early in the process to extend mold life.

FAQ:

What are common defects in extruded parts?

Common defects include flow marks, scratches, ripples, warpage, and weld lines, often caused by mold wear or poor polishing, uneven cooling, temperature mismatch, or improper process parameters.

How much does a mold set cost?

Prices vary widely—simple solid molds typically cost a few hundred to a few thousand dollars, while molds for hollow or complex profiles are significantly more expensive.

How are hollow profiles formed in the mold?

The inner cavity is formed by mandrels and support legs within the mold, which divide the material flow and converge it in the welding chamber; this type of mold has a more complex structure and assembly.

What do you think?

[…] the design and manufacturing process of aluminum extrusion dies, there are several key factors that cannot be ignored. The selection of materials, the design of […]