Market analysis and application of mold industry

1.Current status and prospects of die casting market

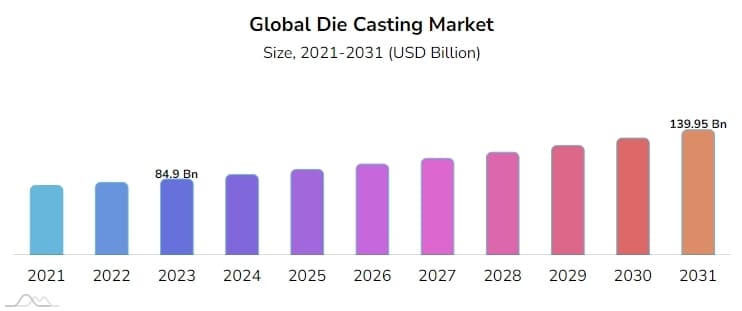

(1) Market size

Demand for die casting continues to grow. The global die casting market size is US$84.9 billion in 2023 and is expected to reach US$139.95 billion by 2031, with a compound annual growth rate of 6.54% from 2024 to 2031.

(2) Market prospects

Die casting is widely used in many industries, among which the demand in the automotive industry is particularly significant. Aluminum alloy has become one of the ideal materials for lightweighting automobiles with its moderate cost and excellent performance. It has high corrosion resistance, low density, good forming and cutting performance, significant weight reduction performance and cost-effectiveness. Energy conservation and emission reduction policies promote the development of light vehicles. The state strictly regulates the fuel consumption and emissions of fuel vehicles.

Lightweight technology can improve fuel efficiency, improve handling and safety, and increase comfort. The demand for lightweighting of new energy vehicles continues to grow. Although the three-electric system and intelligent equipment make the vehicle heavier, lighter weight can increase the cruising range. At present, the application of aluminum alloys in parts such as new energy vehicle body structures has growth opportunities and market potential. With the deepening of the application of aluminum alloys in the automotive industry, the penetration rate of aluminum automotive parts will increase and the market size will continue to expand.

2.Introduction to die casting process

Die casting is an automated process of pressing molten alloy into a mold under high pressure and high speed. Once the alloy is heated to a high temperature and melted, it is injected into the mold under high pressure. The morphology is divided into two halves, one is static and the other is movable. After the molten metal is injected and solidified, the casting has an accurate shape and a smooth surface. A set of molds can be used multiple times and is suitable for mass casting.

3.Industries using die casting

(1) Automobile industry

The automotive industry uses lightweight castings to produce various parts such as engine bracket components, windshield wiper components, etc.

(2) Construction industry

The construction industry requires casting to produce durable and precise parts such as buildings, bridges, storefronts, window frames, and plumbing fixtures. Aluminum castings are widely used in the construction industry due to their light weight and high heat resistance.

(3) Electronics industry

It can realize rapid prototyping of electronic parts and professional equipment for producing heat sinks, internal frames, electronic housings, etc.

(4) Furniture industry

Furniture materials adopt casting process, including handles, door locks, etc., with advantages such as high precision, multi-functional installation, seamless and beautiful appearance.

(5) Aerospace industry

It is used to manufacture large and small aircraft parts. Common alloys include various types of aluminum, cobalt-based alloys, stainless steel, etc., which are used in fuel systems, engines and other parts.

(6) Healthcare

Durable, high strength, easy to manufacture, with complex geometric shapes and requiring less machining. Aluminum and zinc alloys are often used in medical equipment such as surgical equipment, diagnostic equipment, etc.

(7) Cooking industry

It is used to manufacture covers for stoves, ovens, frying pans, etc. Die-cast aluminum is widely used in the manufacture of stoves due to its excellent thermal conductivity.

(8) Telecommunications industry

Manufacturing of telecommunications equipment such as substrates, heat sinks, network equipment, etc.

(9) Industrial field

Production of industrial parts such as rotors, stators and impellers.

(10) Power industry

Production of RF filling repeaters, tower shells, etc.

(11) Lighting industry

Manufacturing of LES radiator systems, LED street lamp shells, etc.

(12) Household appliance production

Production of Vraje wheel belts, vacuum cleaner bodies, etc.

4.Conclusion

Die casting has a wide range of applications and can be used in many industries such as automobiles, electronics, aviation, energy, industry, telecommunications, etc. Understanding its applications in different industries will help us better understand the impact of the die casting industry on the world.