Comprehensive analysis of the stainless steel max temperature before color change

In the application process of stainless steel, temperature is a factor that cannot be ignored. The stainless steel max temperature before color change directly affects its service life and performance. This article will deeply explore the stainless steel max temperature before color change and the scientific principles behind it, related applications, influencing factors and protective measures.

1.Scientific principles of the stainless steel max temperature before color change

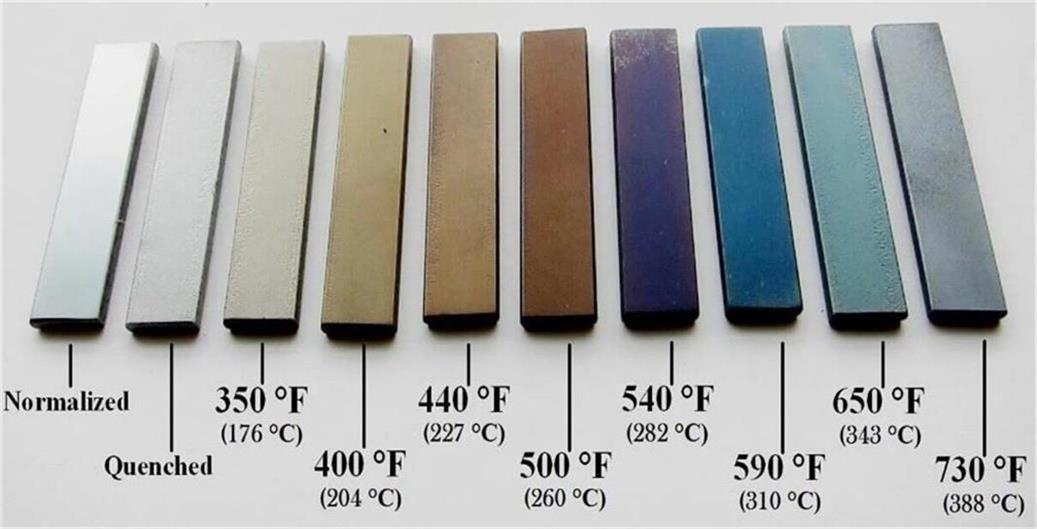

The stainless steel max temperature before color change refers to the temperature below which the stainless steel surface will not undergo obvious color changes. Generally speaking, stainless steel is silvery white at room temperature, but when heated to a certain temperature, the surface will gradually change color due to oxidation. Common stainless steel types such as 304 have a maximum temperature before color change of approximately 400-500°C.

(1) Color change mechanism and oxidation reaction

The mechanism of stainless steel changing color at high temperature is mainly related to the change of the oxide film. This oxide film is mainly composed of chromium oxide, nickel oxide and other metal oxides. When the temperature reaches a certain value, the oxide film on the surface of the stainless steel begins to decompose and re-form new oxides.

These newly formed oxides have different colors, which causes the stainless steel surface to change color. As the temperature rises, the type and thickness of the oxide will also change, causing the color of the stainless steel surface to gradually change from light yellow, blue, and purple to dark blue, gray, or even black.

(2) Microstructure changes

In addition to oxidation reactions, high temperatures may also cause changes in the microstructure of stainless steel. For example, long-term exposure of austenitic stainless steel to high temperatures may cause carbide precipitation, affecting its corrosion resistance and mechanical properties. Although these microstructural changes are difficult to detect with the naked eye, they will have a profound impact on the overall performance of the material.

(3) Color change temperature range

The color change temperature range of stainless steel is generally between 300°C and 900°C. Different types of stainless steel have slightly different color change temperatures due to differences in composition and microstructure. For example, 304 stainless steel begins to slightly change color at about 400°C, while 316 stainless steel has better oxidation resistance due to the addition of molybdenum, and the color change temperature is relatively high, generally starting to change color at around 800°C.

2.The highest temperature before several common stainless steels change color

(1) 304 stainless steel:

304 stainless steel is one of the most common types of stainless steel. The stainless steel max temperature before color change is usually 400℃ to 500℃. High temperature will cause the surface oxide film of stainless steel to change, and the color will change from the original silver to yellow-brown or dark brown.

(2) 316 stainless steel:

316 stainless steel contains molybdenum and has better corrosion resistance. The stainless steel max temperature before color change is usually between 800℃ and 900℃. The color will gradually change at high temperature.

(3) 303 stainless steel:

The color change temperature of 303 stainless steel is relatively low. Generally, the color will change when the temperature exceeds 400℃, and it will usually appear yellow-brown or dark brown.

(4) 310S stainless steel:

This stainless steel has excellent high temperature resistance and its color change temperature is relatively high. The highest temperature before 310S stainless steel changes color is generally between 900℃ and 1000℃.

(5) 430 stainless steel:

The maximum temperature of 430 stainless steel before discoloration is between 600℃ and 700℃. As the temperature rises, the surface color changes from silver to blue or purple.

3.In which applications should special attention be paid to the stainless steel max temperature before color change?

Understanding the stainless steel max temperature before color change is of great significance for industrial production and material application. The following are several major application areas:

(1) Heat treatment process

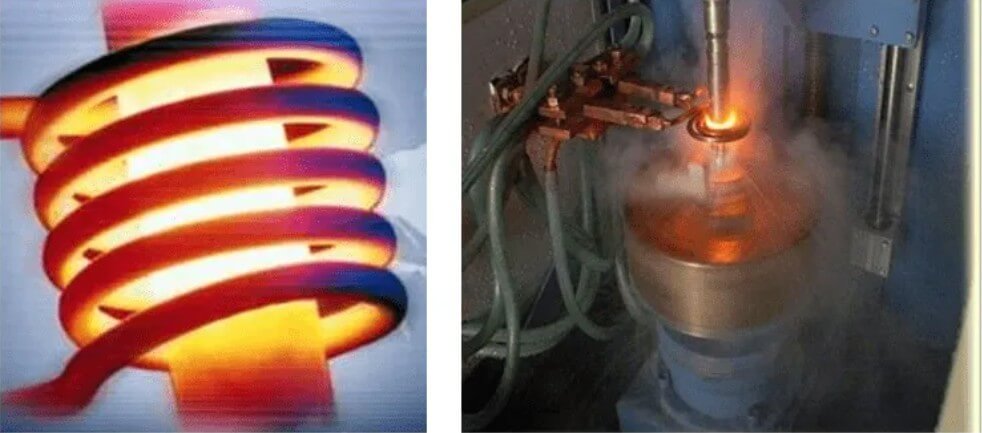

In the heat treatment process of stainless steel, it is crucial to control the heating temperature. Heat treatment usually includes solution treatment and aging treatment, the purpose of which is to optimize the mechanical properties and corrosion resistance of the material.

The temperature of solution treatment is generally higher than the maximum temperature of stainless steel before discoloration, usually between 1000-1150°C, so that carbides can be fully dissolved. It is then rapidly cooled to maintain the austenite structure. Aging treatment is usually carried out at a lower temperature to prevent discoloration of the material surface.

(2) Welding process

Welding is one of the common processes in stainless steel processing. During the welding process, the temperature of the welding area will far exceed the stainless steel max temperature before color change. Therefore, appropriate treatment is required after welding, such as post-weld heat treatment or pickling, to remove the surface oxide scale and restore the corrosion resistance of stainless steel.

In the welding process, controlling the welding temperature and time to prevent the structural changes and performance degradation caused by overheating is the key to ensuring the welding quality.

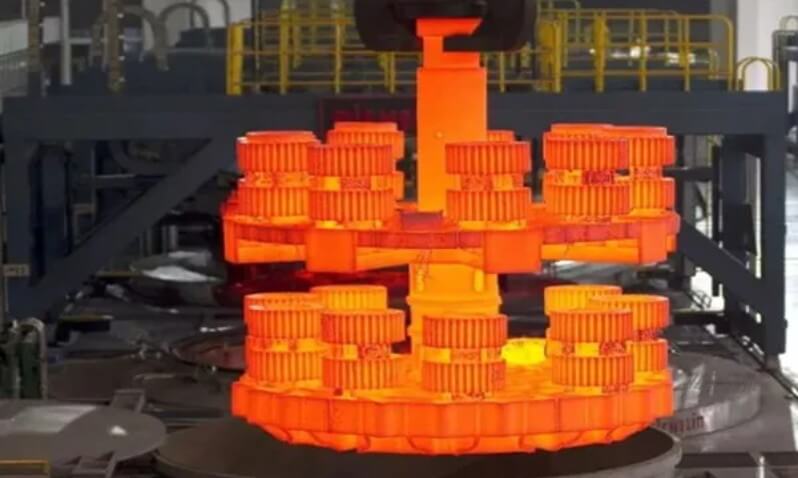

(3) High temperature environment application

In high temperature environments, such as furnaces, engine parts and chemical equipment, the selection and use of stainless steel need to pay special attention to its maximum temperature before discoloration. For example, when the temperature of 304 stainless steel exceeds 600°C, the formation rate of surface oxide scale will increase significantly, resulting in a decrease in the corrosion resistance of the material.

Therefore, in these applications, stainless steel materials with higher heat resistance, such as 310S or Inconel series, are usually selected.

4.Factors affecting the maximum temperature of stainless steel before discoloration

The stainless steel max temperature before color change is affected by many factors. Understanding these factors can help us better control and utilize the discoloration phenomenon of stainless steel.

(1) Material composition

The composition of stainless steel has a significant effect on its discoloration temperature. Different types of stainless steel have slightly different discoloration temperatures due to differences in composition and microstructure.

For example, stainless steel with a higher chromium content has better oxidation resistance and a relatively higher discoloration temperature; while stainless steel with a higher nickel content has better toughness and impact resistance, but its oxidation resistance may be slightly inferior.

(2) Heating time

Heating time is also an important factor affecting the stainless steel max temperature before color change. At the same temperature, the longer the heating time, the easier it is for the oxide film on the surface of the stainless steel to decompose and reform, resulting in more obvious discoloration. Therefore, in practical applications, it is necessary to control the heating time according to the specific situation to avoid obvious discoloration on the stainless steel surface.

(3) Environmental medium

The environmental medium also has an important influence on the stainless steel max temperature before color change. In an oxidizing environment, the oxide film on the surface of stainless steel is more likely to decompose and reform, resulting in more obvious discoloration. In a reducing environment, the oxide film on the surface of stainless steel is relatively stable and the discoloration is relatively unobvious.

Therefore, in practical applications, it is necessary to select appropriate materials and processes according to specific environmental conditions to ensure the performance and aesthetics of stainless steel.

5.What properties of stainless steel will be affected by high temperature discoloration?

The discoloration of stainless steel at high temperature not only affects its appearance, but also has many effects on the performance of the material. The following are several main aspects:

(1) Corrosion resistance

The oxidation reaction caused by high temperature will destroy the passivation film on the surface of stainless steel and reduce its corrosion resistance. The formation of oxide film not only affects the appearance, but also may cause local corrosion phenomena such as pitting and crevice corrosion.

Therefore, when using stainless steel in a high temperature environment, it is necessary to take appropriate protective measures, such as coating protection or selecting stainless steel materials with higher temperature resistance.

(2) Mechanical properties

The microstructural changes of stainless steel at high temperature may cause its mechanical properties to decrease. For example, the precipitation of carbides will increase the hardness and strength of the material, but reduce the plasticity and toughness.

In addition, high temperature may also cause the grain coarsening of the material, further reducing its mechanical properties. Therefore, when using stainless steel in a high temperature environment, appropriate heat treatment is required to restore or optimize its mechanical properties.

(3) Processing properties

The processing properties of stainless steel at high temperature will also be affected. At high temperatures, the strength and hardness of materials decrease, which is conducive to plastic deformation, but too high a temperature may cause overheating and overburning of the material, affecting its subsequent processing and performance. Therefore, during high-temperature processing, the temperature and time need to be strictly controlled to ensure the processing quality of the material.

6.Understand the stainless steel max temperature before color change and the corresponding protective measures

In order to prevent stainless steel from discoloring at high temperatures, the following protective measures can be taken:

(1) Selecting suitable materials

According to the specific application environment and requirements, selecting suitable materials is also an important measure to prevent stainless steel from discoloring. For example, in a high-temperature environment, stainless steel materials with better antioxidant properties can be selected, such as stainless steel containing molybdenum, titanium and other elements. These materials have better stability and antioxidant properties at high temperatures, which can effectively prevent stainless steel from discoloring.

(2) Surface treatment

Appropriate treatment of the stainless steel surface, such as nickel plating, chrome plating, etc., can form a protective film on the stainless steel surface, effectively preventing oxygen from corroding the stainless steel matrix, thereby improving the antioxidant and corrosion resistance of stainless steel. These surface treatment methods can not only prevent stainless steel from discoloring, but also improve the wear resistance and aesthetics of stainless steel.

(3) Optimization of heat treatment process

By optimizing the heat treatment process, the mechanical properties and corrosion resistance of stainless steel can be improved. For example, the combination of solution treatment and aging treatment can effectively prevent carbide precipitation and maintain the stable performance of the material.

(4) Temperature control

In practical applications, the working temperature of stainless steel needs to be strictly controlled to avoid long-term exposure to high temperature environment. By optimizing process design and equipment structure, the temperature load of stainless steel can be reduced, thereby preventing it from obvious discoloration.

In addition, regular maintenance of equipment and timely detection and repair of overtemperature problems are also effective measures to prevent stainless steel from discoloring.

(5) Environmental control

When using stainless steel in a high temperature environment, controlling environmental conditions is also an important means to reduce the degradation of material performance. For example, by controlling the oxygen content in the air, lowering the ambient temperature or using inert gas protection, the oxidation reaction of stainless steel can be effectively reduced and its service life can be increased.

7.Conclusion

The stainless steel max temperature before color change is one of the important factors affecting its performance. Understanding this characteristic and its impact on material performance is of great significance for industrial production and material application.

By selecting appropriate materials, optimizing heat treatment processes, adopting surface treatment technology and controlling environmental conditions, the impact of high temperature on the performance of stainless steel can be effectively reduced, ensuring its stability and reliability in different application environments.