A complete analysis of cast iron casting process: materials, processes and applications

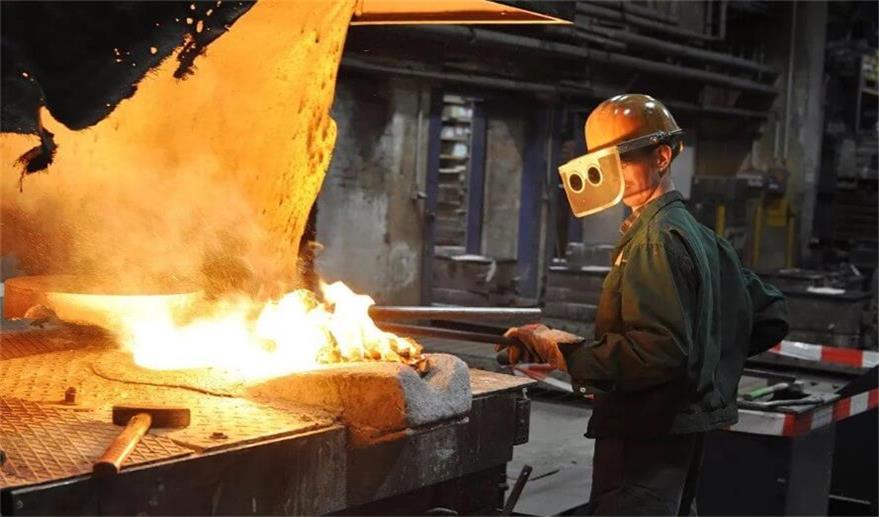

Cast iron casting is a method of melting an iron-carbon alloy into a liquid state, pouring it into a pre-prepared mold, and then cooling and solidifying it to obtain a cast iron part with a certain shape and performance.

This method occupies an extremely important position in industrial production because it can produce parts with complex shapes and precise dimensions, and is widely used in many fields such as automobiles, machinery, and construction.

The reason why cast iron casting is important is that the cast iron material itself has excellent mechanical properties, such as high strength, wear resistance and fatigue resistance. These properties enable cast iron parts to operate stably for a long time in harsh working environments. This article will provide a detailed analysis of the materials, processes and applications of cast iron casting.

1.Classification of cast iron

Cast iron is an alloy with iron, carbon and silicon as the main components. It can be divided into the following categories according to the graphite morphology and properties:

(1) Gray cast iron:

●High carbon content (generally 2.5%~4%), and graphite is distributed in flakes.

●It has good shock absorption, wear resistance and machinability.

● Mainly used for machine tool beds, pipes, engine blocks, etc.

(2) Ductile iron:

● By adding spheroidizers, graphite is distributed in a spherical shape to improve the mechanical properties of the material.

● It has high strength, toughness and corrosion resistance.

● Mainly used for high-strength pipes, automotive parts, agricultural machinery, etc.

(3) White cast iron:

● Carbon exists in the form of cementite, which has high hardness but high brittleness.

● Suitable for wear-resistant parts, such as rollers, wear-resistant liners, etc.

(4) Malleable cast iron:

● Through annealing treatment, toughness is improved to give it good plasticity and ductility.

● Mainly used for parts that require high toughness, such as automotive parts, tools, etc.

2.Cast iron casting process analysis

The cast iron casting process is diverse, and each casting process has its applicable parts.

(1) Die casting

1) Process characteristics:

● Molten metal is injected into a metal mold under high pressure and quickly cooled to form.

● Suitable for mass production of high-precision, small and complex parts.

2) Advantages:

● High dimensional accuracy of castings, good surface quality, and reduced need for subsequent processing.

● High production efficiency, suitable for large-scale automated production.

3) Disadvantages:

● High equipment investment cost and high mold manufacturing cost.

● Suitable for parts with thin-walled structures, with high requirements for material fluidity.

4) Applications:

● Automobile engine housing, small precision parts.

(2) Continuous casting

1) Process characteristics:

● Molten metal passes through a water-cooled crystallizer to form a long billet, which is then cut and processed.

● Suitable for the production of long-sized castings, such as cast iron pipes, cast iron bars, profiles, etc.

2) Advantages:

● Improve material utilization and reduce waste.

● Dense structure, reduce casting defects, and improve casting quality.

3) Disadvantages:

● High process requirements, requiring strict control of cooling rate and crystallization process.

●Limited scope of application, mainly used for long strip structural parts.

(3) Centrifugal casting

1) Process characteristics:

●Rely on centrifugal force to throw the molten metal into the rotating mold to solidify it.

●Applicable to the manufacture of axisymmetric parts, such as pipes, cylinder liners, brake drums, etc.

2) Advantages:

●Dense material structure, reducing pores and shrinkage defects.

●High production efficiency, can manufacture thick-walled, pressure-resistant castings.

3) Disadvantages:

●Only suitable for castings with circular or symmetrical structures.

●Large equipment investment, high initial cost.

(4) Investment casting

1) Process characteristics:

●First, make a model with wax, then use ceramic coating to form a casting, and finally melt the wax product and inject metal.

●Applicable to the manufacture of high-precision, complex structure castings.

2) Advantages:

●Complex parts can be formed in one go, reducing the amount of processing.

●Excellent surface quality and high dimensional accuracy.

3) Disadvantages:

● High cost and complex process.

● Long production cycle, not suitable for mass production at low cost.

4) Applications:

● Aerospace, medical equipment, high-precision mechanical parts.

3.Heat treatment process of cast iron parts

The heat treatment process after cast iron casting plays a key role in its final performance. Different heat treatment methods can optimize the mechanical properties of the casting, improve its wear resistance or reduce its brittleness, making it more suitable for specific applications.

(1) Annealing:

● Mainly used to reduce the hardness of cast iron, improve machinability, and eliminate internal stress.

● Annealing temperature is generally 800~900℃, and slowly cooled to room temperature.

● Suitable for cast iron casting parts that require further machining, such as machine tool beds and gearbox housings.

(2) Normalizing:

● Improve the strength and wear resistance of castings by air cooling after high temperature heating.

● Mainly used for ductile iron parts that require higher mechanical properties, such as crankshafts and connecting rods.

(3) Quenching:

● Rapid cooling improves surface hardness and makes castings more wear-resistant.

● Often used in combination with surface induction quenching to improve local hardness and extend service life.

● Typical applications include brake discs, wear-resistant linings, etc.

(4) Tempering:

● Used to eliminate brittleness after quenching and improve comprehensive mechanical properties.

● Low-temperature tempering is used to improve hardness, medium-temperature tempering balances strength and toughness, and high-temperature tempering is suitable for parts that withstand greater impact.

● For example, key components of automobile engines are often tempered to optimize performance.

4.Application areas of cast iron casting

Cast iron occupies an important position in many industrial fields due to its excellent mechanical properties and castability.

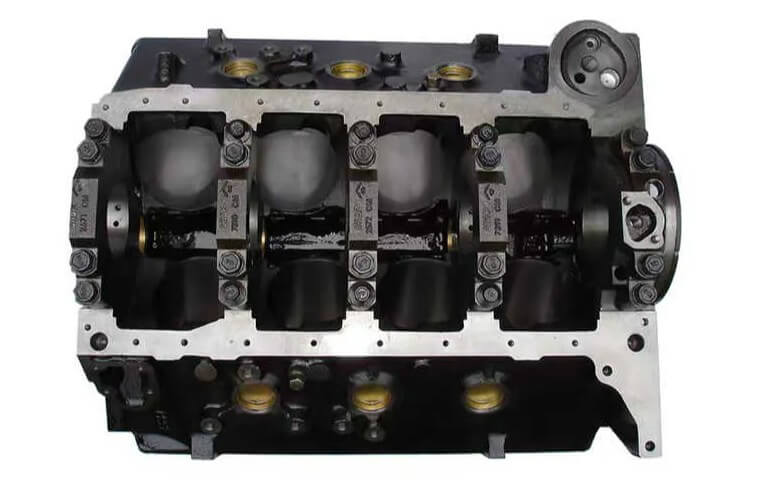

(1) Automobile manufacturing:

● Cast iron casting technology is widely used in automobile manufacturing, such as the production of engine cylinders, crankshafts, brake discs, etc.

● These components require good wear resistance and strength, and require low production costs.

●For example, gray cast iron is used in engine blocks due to its good damping properties, while ductile iron is used in suspension system components due to its high strength.

(2) Mechanical manufacturing:

●Key parts such as machine tool beds, gearboxes, and bearing seats are usually made using cast iron casting technology.

●Machine tool beds require high rigidity and good shock absorption, while the self-lubricating properties of cast iron help the long-term operation of gearboxes.

(3) Construction industry:

●Cast iron pipes are widely used in water supply and drainage systems due to their excellent corrosion resistance and high strength.

●Manhole covers, bridge structures, etc. are also often made of ductile iron to improve durability.

(4) Home and art castings:

●Cast iron casting technology can be used to produce highly decorative railings, sculptures, gardening supplies, etc.

●Modern casting technology can produce cast iron artworks with complex patterns and exquisite surfaces.

5.Conclusion

As an important manufacturing process, cast iron casting plays an irreplaceable role in modern industry. By having a deep understanding of the classification, casting process, heat treatment process and application fields of cast iron, we can better master cast iron casting technology and promote its application and development in various fields.