Carbon Steel vs Cast Iron: Who Wins?

Carbon steel vs cast iron, as two metal materials widely used in industry and construction, each has its own unique properties and advantages. When selecting materials suitable for a specific application, it is critical to understand their properties. Carbon steel is known for its strength and malleability, while cast iron dominates the market for its wear resistance and low cost. This article will delve into the differences between carbon steel and cast iron to help you make a wise choice in different application scenarios.

1.Carbon steel vs cast iron: basic concepts and component distinctions

(1) Definition and composition of carbon steel

Carbon steel, as the name suggests, is an alloy mainly composed of iron and carbon, with a carbon content usually between 0.0218% and 2.11%. In addition to iron and carbon, carbon steel also contains small amounts of manganese, silicon, sulfur, phosphorus and other elements. Although these elements are not high in content, they have an important impact on the performance of carbon steel. Manganese and silicon can enhance the strength of carbon steel, while sulfur and phosphorus are generally considered harmful elements and will reduce the plasticity and toughness of carbon steel.

According to the different carbon content, carbon steel can be divided into low carbon steel, medium carbon steel and high carbon steel. Each type of carbon steel has different performance characteristics and application fields.

(2) Definition and composition of cast iron

Cast iron is an iron-carbon alloy with a carbon content of more than 2.11%. Cast iron has a higher carbon content than carbon steel, which gives cast iron very different performance characteristics than carbon steel. In addition to high levels of carbon, cast iron also contains high amounts of silicon, manganese, sulfur, phosphorus and other elements.

Carbon in cast iron mainly exists in the form of graphite. The presence of graphite gives cast iron many unique properties, such as good casting performance, cutting performance and wear resistance. Cast iron can be divided into gray cast iron, ductile cast iron, malleable cast iron and vermicular graphite cast iron according to the shape of graphite. Each type of cast iron has its specific application scenarios.

2.Carbon Steel vs Cast Iron: Comparison of Physical and Mechanical Properties

Carbon steel vs cast iron are two common iron-carbon alloys that have significant differences in their physical and mechanical properties. Here are their main differences:

(1) Hardness and toughness of carbon steel

The properties of carbon steel vary depending on the carbon content. Mild steel has lower carbon content, so its hardness is lower, but its plasticity and toughness are good. It is widely used in applications that require good formability, such as automobile bodies and building structures. Medium carbon steel has moderate carbon content, has high hardness, and maintains good plasticity and toughness. It is suitable for manufacturing mechanical parts and tools. High carbon steel has a high carbon content and has extremely high hardness and strength, but poor plasticity and toughness. It is mainly used to manufacture high-strength components such as springs and knives.

(2) Hardness and brittleness of cast iron

Cast iron has high hardness due to its high carbon content, but is also correspondingly brittle. This means that cast iron is more susceptible to cracking when impacted, making it unsuitable for applications requiring high toughness. Nonetheless, the good casting properties and machinability of cast iron give it an advantage when manufacturing parts with complex shapes. In addition, cast iron also has good wear resistance and vibration absorption, and is widely used in mechanical bases, piping systems and other fields.

3.Carbon steel vs cast iron: differences in processing technology and applicable scenarios

(1) Processing characteristics of carbon steel

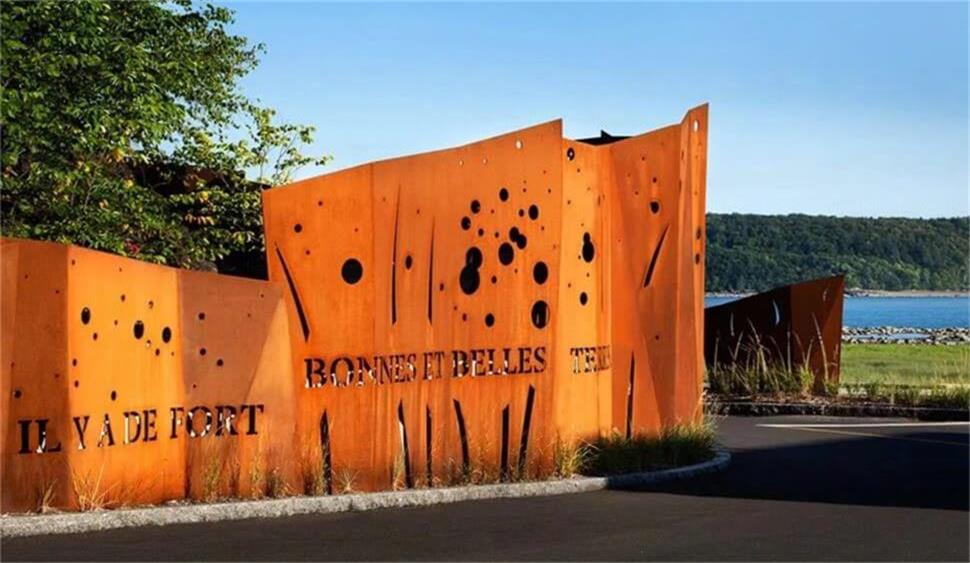

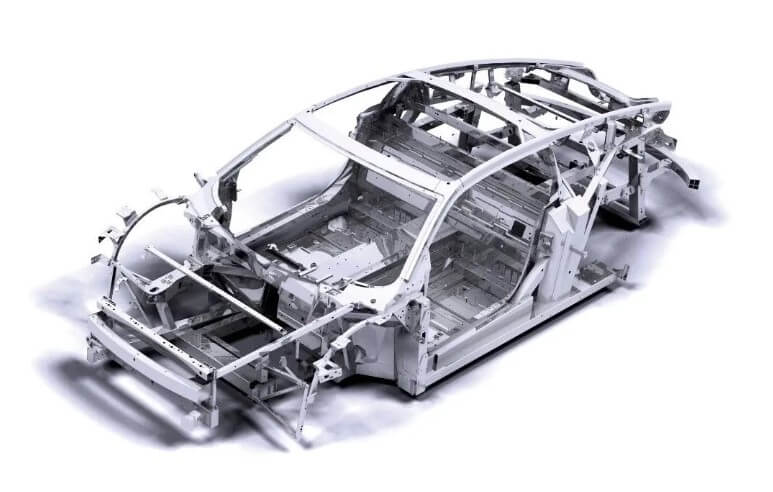

Carbon steel is easy to forge, roll and weld due to its good ductility and toughness. This makes carbon steel an ideal material for manufacturing a variety of mechanical parts and structural components. For example, carbon steel is widely used in beams and columns in building structures, body frames in the automotive industry, and various parts in machine manufacturing. The welding performance of carbon steel is particularly outstanding, making it occupy an important position in modern manufacturing.

(2) Casting properties of cast iron

Cast iron is known for its excellent casting properties and is suitable for producing parts with complex shapes. Cast iron has good fluidity and easily fills molds, so complex and delicate structures can be formed during the casting process. Cast iron is often used to produce pipes, valves, machine bases and other components. Cast iron also has good cutting performance and is suitable for various mechanical processing, such as turning, milling, drilling, etc.

4.Carbon steel vs cast iron: differences in typical application fields

(1) Application of carbon steel

Carbon steel is widely used in many fields due to its balance of strength and ductility. In building structures, carbon steel is used to manufacture load-bearing components such as beams and columns to ensure the safety and stability of the building. In the field of machinery manufacturing, carbon steel is used to produce various mechanical parts, such as shafts, gears, etc., and is favored for its good mechanical properties. In the automotive industry, carbon steel is used to manufacture key components such as body frames and suspension systems to ensure the strength and safety of the car.

(2) Application of cast iron

Cast iron is mainly used to manufacture piping systems, mechanical bases and heat processors due to its good casting properties and wear resistance. In urban infrastructure, cast iron pipes are widely used for their corrosion resistance and long life. The mechanical base utilizes the high damping properties of cast iron to effectively reduce vibration during machine operation and improve the stability and service life of the equipment. In heat treatment equipment, the good heat resistance of cast iron makes it an ideal material for manufacturing furnaces and heat exchangers.

5.Carbon Steel vs Cast Iron: Cost and Economic Considerations

(1) Cost of carbon steel

The production cost of carbon steel is relatively high, mainly because its production process is complex and requires strict control of ingredients and heat treatment processes. However, due to its excellent mechanical properties, carbon steel is more economical in applications requiring high strength and high plasticity. For example, in the automotive and construction industries, although the initial investment is higher, the long life and reliability of carbon steel reduce the overall cost.

(2) Cost of cast iron

Cast iron is less expensive to produce, mainly due to its simple production process and cheap raw materials. Cast iron is mainly produced by casting, which allows complex shapes to be manufactured on a large scale, so it is more common in some applications where strength is not required. For example, in the production of pipes and machine bases, the low cost of cast iron makes it highly economical.

6.Carbon steel vs cast iron: analysis and summary of advantages

(1) Advantages of carbon steel

The main advantages of carbon steel are its high strength and good ductility, which make it excellent in applications that need to withstand heavy and dynamic loads. In addition, carbon steel also has good welding and processing properties, is easy to manufacture and repair, and is widely used in construction, machinery manufacturing, automobile industry and other fields.

(2) Advantages of cast iron

Cast iron is known for its good casting properties and cutting performance, and is suitable for producing parts with complex shapes. Cast iron is lower cost, suitable for mass production, and has a wide range of applications in areas such as piping systems, machine bases, and heat handlers.

7.Summary

Through the above analysis, we can see that carbon steel vs cast iron each has its own unique performance characteristics and scope of application. The choice of carbon steel vs cast iron depends on specific application needs, cost considerations and performance requirements. In practical applications, engineers and designers need to select the most appropriate materials based on the specific use environment and performance requirements to ensure product performance and economy.