C10 weathered steel characteristics analysis: comprehensive analysis of corrosion resistance and application advantages

C10 weathered steel is a high-strength low-alloy steel between ordinary steel and stainless steel. With its excellent weather resistance, beautiful appearance and good processing performance, it has been widely used in bridges, buildings, towers, railway vehicles, containers and other fields. This article will discuss in detail the characteristics, applications, advantages, composition design, processing technology and comparison between C10 weathered steel and ordinary steel and stainless steel.

1.Characteristics of C10 weathered steel

C10 weathered steel is a low-alloy high-strength steel containing alloy elements such as copper, chromium and nickel. Its unique composition makes it have excellent corrosion resistance in the atmospheric environment. The following are its main characteristics:

(1) Excellent weather resistance:

C10 weathered steel contains an appropriate amount of alloy elements. These elements form a dense and stable oxide film on the surface of the steel, which effectively prevents corrosive media such as oxygen and water vapor in the atmosphere from further eroding the interior of the steel. This allows it to maintain its original mechanical properties and appearance for a long time when exposed to the natural environment. Compared with ordinary carbon steel, the corrosion resistance of C10 weathered steel can be improved by 2-8 times.

(2) Good processing performance:

C10 weathered steel has good weldability, cuttability and plasticity, and can meet various complex processing requirements. During the welding process, its weld quality is excellent, and the welded joint has good strength and toughness. In addition, it can be processed by cold bending, stamping and other processes to make components of various shapes and sizes.

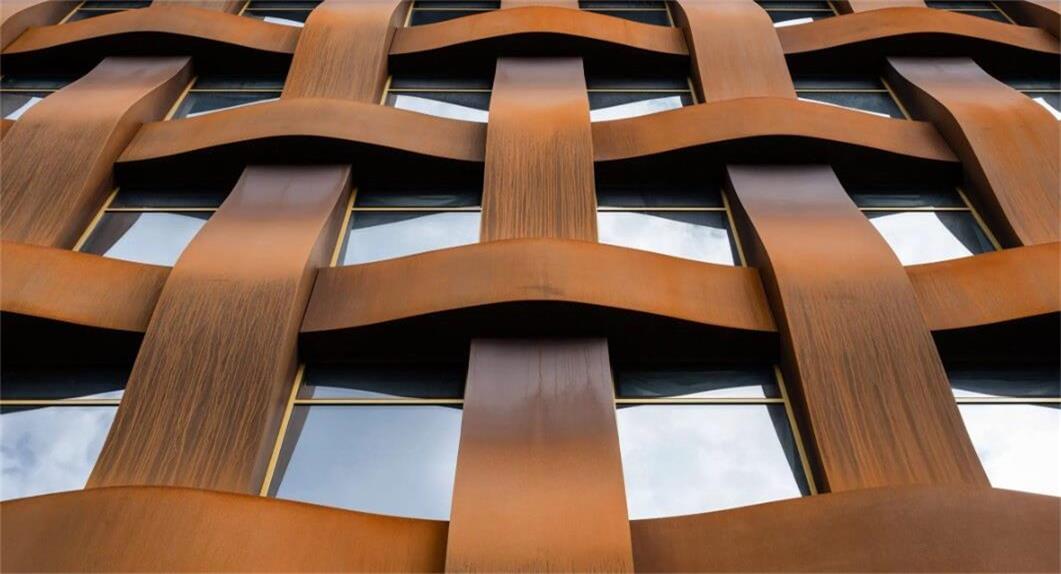

(3) Unique appearance effect:

C10 weathered steel will gradually form a rust-red oxide film in the natural environment. This oxide film not only has a decorative effect, but also can further improve the weather resistance of the steel. This rust-red appearance adds a natural and simple beauty to works such as architecture and sculptures, and is deeply loved by designers and artists.

(4) Economical:

Although the initial cost of weathered steel may be higher than that of ordinary carbon steel, its excellent weather resistance means longer service life and lower maintenance costs. In the long run, the use of weathered steel has significant economic benefits.

2.Application fields of C10 weathered steel

(1) Bridge construction:

C10 weathered steel is widely used in bridge construction. This steel has excellent atmospheric corrosion resistance, which can significantly extend the service life of bridges and reduce maintenance costs. Its high strength and good welding performance make the bridge structure more durable and perform well in various complex environments.

(2) Construction field:

In the construction field, weathered steel is used as exterior wall decoration, roofing materials, etc. Its unique weather resistance enables it to maintain its beauty and stability for a long time when exposed to the external environment, reducing maintenance requirements. At the same time, its strong modeling ability can meet the diverse needs of architects.

(3) Tower structure:

C10 weathered steel is suitable for the manufacture of various tower structures, such as communication towers, power towers, etc. This type of structure is exposed to the atmosphere for a long time, and has extremely high requirements for the corrosion resistance of the material. It can meet these requirements and ensure the safety and stability of the tower.

(4) Railway vehicles:

C10 weathered steel plays an important role in railway vehicle manufacturing. It not only has excellent weather resistance, but also can reduce the vehicle’s own weight and improve operating efficiency. At the same time, its good processing performance makes vehicle manufacturing more convenient.

(5) Container manufacturing:

It is widely used in the manufacture of containers. Since containers are in various harsh transportation environments for a long time, the corrosion resistance of weathered steel can effectively extend the service life of containers and reduce transportation costs.

3.Advantages of C10 weathered steel

(1) Environmental protection:

Compared with the traditional method of using coatings or plating to prevent corrosion, weathered steel forms a protective film through the characteristics of its own alloy elements, without the need for additional coating treatment, reducing environmental pollution. In addition, its recyclability also makes it have better environmental protection performance.

(2) Low maintenance cost:

Due to the excellent weather resistance of weathered steel, it almost does not require maintenance during use, greatly reducing maintenance costs. This is especially important for some large-scale buildings and bridge projects, which can significantly reduce long-term maintenance costs and manpower investment.

(3) Design flexibility:

The good processing performance of C10 weathered steel enables it to meet various complex architectural design requirements. Designers can freely design building components of various shapes and structures according to their own creativity and needs, giving full play to the potential of the material.

(4) High safety:

It not only has high strength and good toughness, but also can prevent corrosion through its own oxide film, thereby improving the safety of structures such as buildings and bridges.

4.Composition design and processing technology of C10 weathered steel

(1) Carbon (C):

The carbon content of C10 weathered steel is usually between 0.07% and 0.12%. Carbon is an important factor in determining the strength and hardness of steel. An appropriate amount of carbon content can ensure that the steel has good mechanical properties while avoiding the increase in brittleness caused by excessive carbon content.

(2) Silicon (Si):

The silicon content is generally between 0.2% and 0.5%. Silicon can improve the strength and hardness of steel, while enhancing its anti-oxidation and weathered resistance.

(3) Manganese (Mn):

The manganese content is usually between 0.5% and 1.0%. Manganese is a good deoxidizer and desulfurizer, which can improve the strength and toughness of steel.

(4) Phosphorus (P):

The phosphorus content is generally controlled below 0.04%. Although phosphorus can improve the strength and hardness of steel, excessive phosphorus will reduce the plasticity and toughness of steel, especially in low temperature environments.

(5) Sulfur (S):

The sulfur content is generally controlled below 0.03%. Sulfur is a harmful element in steel and will reduce the mechanical properties and weather resistance of steel.

(6) Chromium (Cr):

The chromium content is generally between 0.8% and 1.2%. Chromium is the main element for improving the weather resistance of steel and can form a dense protective film to effectively prevent corrosion.

(7) Copper (Cu):

The copper content is generally between 0.2% and 0.4%. Copper can further improve the weather resistance of steel, especially in humid environments.

(8) Nickel (Ni):

The nickel content is generally between 0.25% and 0.5%. Nickel can improve the toughness and weather resistance of steel, and improve the corrosion resistance of steel.

5.Processing technology of C10 weathered steel

(1) Smelting process:

Use electric arc furnace or converter to smelt, strictly control the chemical composition, and ensure the uniformity and purity of steel. Deoxidation and desulfurization treatment are required during the smelting process to reduce the impact of harmful elements on the performance of steel.

(2) Rolling process:

C10 weathered steel is usually rolled by hot rolling process. During the rolling process, the heating temperature, rolling pressure and cooling rate need to be strictly controlled to ensure the mechanical properties and surface quality of the steel.

(3) Heat treatment process:

Mainly includes normalizing and tempering treatment. Normalizing treatment can improve the strength and toughness of steel, while tempering treatment can eliminate the stress inside the steel and stabilize the organizational structure.

(4) Surface treatment process:

In order to further improve the weather resistance of C10 weathered steel, it is usually subjected to surface treatment, such as sandblasting, shot peening, pickling, etc. These treatment processes can remove the oxide scale and impurities on the steel surface, improve the surface roughness, and enhance the adhesion of the coating.

(5) Welding process:

C10 weathered steel has good welding performance and can be welded by a variety of welding methods. The welding parameters need to be controlled during the welding process to avoid welding defects. At the same time, appropriate heat treatment is required after welding to eliminate welding stress and improve the performance of the welded joint.

6.What is the difference between C10 weathered steel and ordinary steel?

(1) Composition difference

Ordinary steel is mainly composed of iron and carbon, and may contain a small amount of manganese, silicon and other elements.

C10 weathered steel adds copper, nickel, chromium, titanium, molybdenum and other alloy elements to ordinary carbon steel. The addition of these elements significantly improves its atmospheric corrosion resistance.

(2) Performance characteristics

1) Corrosion resistance:

Steel is prone to rust in the atmospheric environment, and the rust layer cannot play a protective role, resulting in the gradual destruction of the steel plate structure. A stable rust layer will form on the surface of C10 weathered steel. This rust layer acts like a protective film to prevent further intrusion of corrosive media, greatly extending its service life.

2) Strength and toughness:

After adding alloy elements, C10 weathered steel not only maintains the strength of ordinary steel plates, but also performs better in toughness, ductility, fatigue strength, etc.

(3) Price

Ordinary steel production process is relatively simple, and the cost of raw materials is relatively low, so the price is relatively cheap.

Due to the addition of multiple alloy elements, the production process of C10 weathered steel is relatively complex, and the requirements for production equipment and technology are high, so its price is higher than that of ordinary steel.

In summary, C10 weathered steel has changed its performance by adding alloy elements. It is significantly better than ordinary steel in terms of corrosion resistance and has important applications in many fields.

7.What is the difference between C10 weathered steel and 304 stainless steel in terms of corrosion resistance?

(1) Characteristics of C10 weathered steel

Weathering steel is a low alloy steel made by adding a small amount of corrosion-resistant elements such as copper and nickel. Its weather resistance is better than that of ordinary steel.

A uniform and dense rust layer will form on the surface of weathering steel. This rust layer has protective properties and can effectively block the penetration and transmission of corrosive media into the interior of the steel, preventing further corrosion.

(2) Characteristics of 304 stainless steel

304 stainless steel is a general-purpose stainless steel material with good corrosion resistance and heat resistance.

It has good corrosion resistance to oxidants, water vapor and various acid, alkali and other chemical media.

The corrosion resistance of 304 stainless steel mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, etc.) and internal structure.

(3) Application scenarios

Due to its excellent atmospheric corrosion resistance, C10 weathered steel is often used in the manufacture of steel structures such as bridges, buildings, towers, railway vehicles, containers, etc. that are exposed to the atmosphere for a long time.

304 stainless steel is widely used in architectural decoration, petrochemical, food processing, medical equipment, automobile manufacturing and other fields due to its excellent resistance to chemical corrosion.

In summary, C10 weathered steel and 304 stainless steel have their own advantages in corrosion resistance and are suitable for different application scenarios. Weathering steel is more suitable for steel structure projects exposed to the atmospheric environment for a long time, while 304 stainless steel is more suitable for occasions that require resistance to chemical corrosion.

8.Summary

Through comparative analysis, we can see that C10 weathered steel has significant advantages in weather resistance and processability, and is suitable for a variety of complex environments. Compared with ordinary steel and stainless steel, C10 weathered steel shows unique competitiveness in specific application scenarios. In the future, with the continuous development of technology and the growth of market demand, its application field will continue to expand, bringing more innovation and benefits to modern engineering.