The evolution of bullet proof materials: Technological changes from heavy to light

As an important material equipment to protect the lives of soldiers and police, the development history of bullet proof materials is full of technological changes. From the initial heavy steel plates to today’s lightweight and high-performance materials, it has made great progress in terms of protection performance, comfort and portability. This article will take you to understand the evolution of bullet proof materials.

1.Analysis of the importance and development history of bullet proof materials

(1) Importance

Bullet proof materials play a vital role in modern society. They not only protect military personnel from bullets, but are also widely used in law enforcement, security and civilian protection. Bullet proof materials are materials that can resist the invasion of bullets or fragments, such as glass fiber composites, aramid and ultra-high molecular weight polyethylene. They have the advantages of good anti-ballistic performance, light weight and convenient processing.

(2) Development history

The development history of bullet proof materials is long. From the simple armor in ancient times to the metal armor in the Middle Ages, and then to the modern high-tech bulletproof vests, each step of progress reflects the development of materials science and manufacturing technology. Early bullet proof materials mainly relied on the hardness of metals, while modern bullet proof materials make more use of the characteristics of fibers and composite materials to provide lighter and stronger protection.

2.Classification, characteristics, advantages and disadvantages of bullet proof materials

(1) Metal bullet proof materials

Metal bullet proof materials are one of the earliest widely used bullet proof materials, mainly composed of high-strength alloy steel, aluminum alloy, etc.

1) Main characteristics

● High strength: Metal bulletproof materials have extremely high strength and hardness and can effectively resist ballistic attacks.

● Corrosion resistance: Metal materials usually have good corrosion resistance and can be used in various harsh environments.

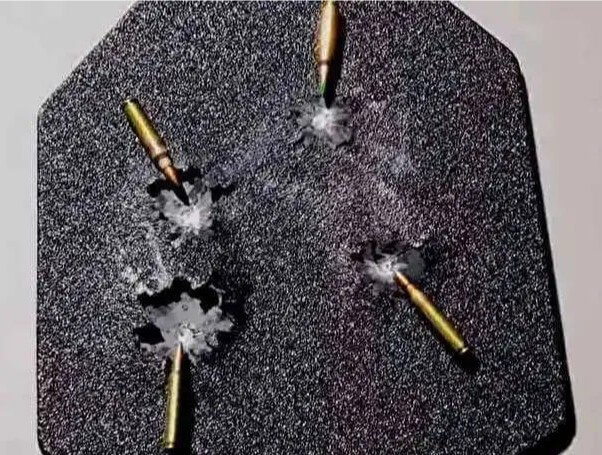

● Reusable: Unlike ceramic materials, metal bulletproof materials are not easy to break after being attacked by ballistics and can be used multiple times.

2) Advantages:

● Good bulletproof performance, especially in the face of high-energy ballistic attacks.

● Mature technology, relatively simple production process, and low cost.

3) Disadvantages:

● Heavy weight, affecting the wearer’s flexibility and comfort.

● Prone to secondary damage: Bullet impact may produce fragments, causing secondary damage.

(2) Ceramic bullet proof materials

Ceramic bullet proof materials are popular because of their high hardness and light weight. They are mainly made of ceramic materials such as alumina and silicon carbide.

1) Main characteristics

● High hardness: The hardness of ceramic materials is much higher than that of metals and most polymer materials, and they can effectively disperse and absorb ballistic energy.

● Light weight: Compared with metal materials, the weight of ceramic bulletproof materials is greatly reduced, which helps to improve the wearer’s flexibility.

● High temperature resistance: Ceramic materials have good high temperature resistance and can still maintain stable performance in extreme environments.

2) Advantages:

● Light weight, which helps to improve the wearer’s mobility.

● High hardness and good bulletproof performance, especially when facing high-speed ballistic attacks.

3) Disadvantages:

● Brittle and easy to break, need to be replaced after being attacked by ballistics.

● High cost and relatively complex production process.

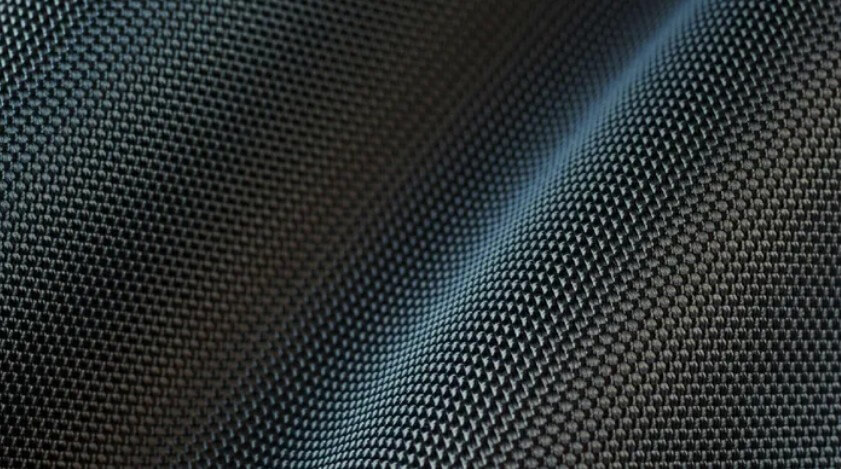

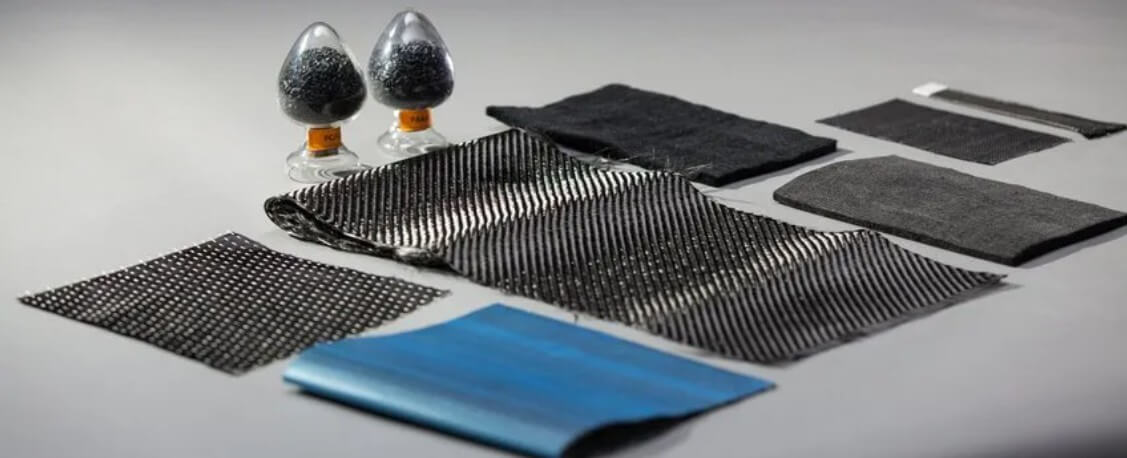

(3) High-performance fiber materials

High-performance fiber materials are an important component of modern bulletproof materials, mainly including Kevlar fiber and ultra-high molecular weight polyethylene (UHMWPE) fiber.

1) Main characteristics

● Softness: High-performance fiber materials are soft, light and comfortable to wear.

● Lightweight: Compared with metal and ceramic materials, the weight of high-performance fiber materials is greatly reduced.

● High strength: The specific strength and specific modulus of these materials are much higher than those of traditional materials, and they can effectively absorb and disperse ballistic energy.

2) Advantages:

● Lightweight and soft, comfortable to wear, and will not affect the wearer’s flexibility.

● Good ballistic performance, can effectively resist various types of ballistic attacks.

● With good stab and cut resistance, it is widely used in protective equipment such as bulletproof vests and helmets.

3) Disadvantages:

● The bulletproof effect of a single-layer fiber material is limited, and usually multiple layers are required.

● In the face of extremely high-energy ballistic attacks, the ballistic performance may be insufficient.

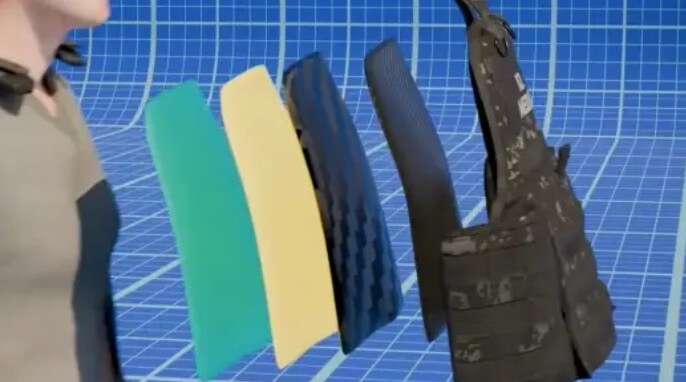

(4) Combined bullet proof materials

Combined bullet proof materials can give full play to the advantages of various materials and provide more comprehensive protection effects by combining materials such as metals, ceramics and high-performance fibers. For example, in bulletproof vests, high-performance fiber materials are usually used in the inner layer to absorb impact energy, and ceramic materials are used in the outer layer to prevent bullet penetration.

1) Main characteristics

● Excellent comprehensive performance: Combined bullet proof materials combine metals, ceramics, fibers and other materials to fully utilize their respective advantages to achieve the best protection effect.

● Flexible design: Materials can be combined and structures can be designed according to different protection needs.

2) Advantages

● Optimal protection performance: Combined bulletproof materials can provide a higher level of protection while taking into account lightness and comfort.

● Strong environmental adaptability: Through material combination, the environmental adaptability problem of a single material can be improved.

3) Disadvantages

● High cost: The production process of combined bulletproof materials is complex, involving multiple materials and processes, and the cost is high.

● High maintenance requirements: The maintenance and care of combined bulletproof materials are relatively complex and require professional treatment.

3.Technological progress of bullet proof materials

(1) Advances in materials science

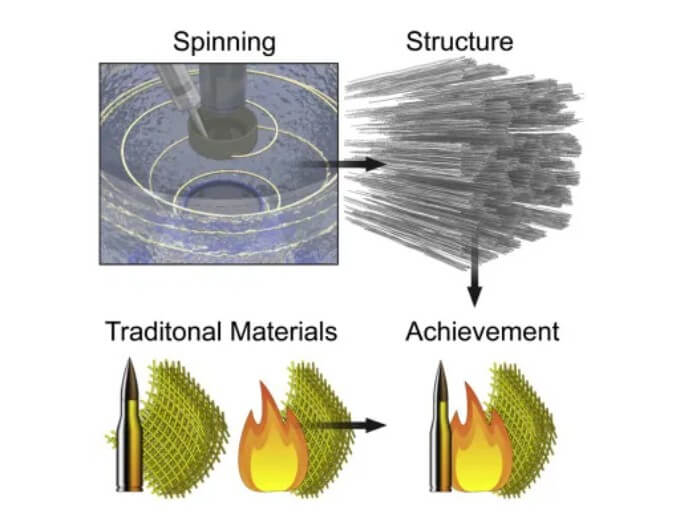

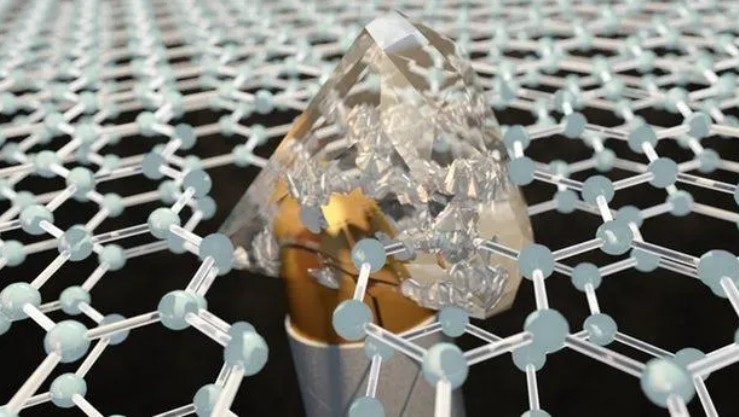

In recent years, with the rapid development of materials science, new bullet proof materials have emerged. For example, nanomaterials such as carbon nanotubes and graphene are considered to be important candidates for future bulletproof materials due to their extremely high strength and modulus. These nanomaterials not only have excellent mechanical properties, but also have good flexibility and durability, and can maintain stable performance under extreme environments.

(2) Computer simulation and design optimization

Computer simulation technology plays a key role in the research and development of bulletproof materials. Through simulation techniques such as finite element analysis, researchers can predict the behavior of materials under different conditions and optimize the design and structure of materials. For example, using Abaqus software to simulate the strain mode of PDMS (polydimethylsiloxane) substrate can accurately calculate its stretchability, providing a scientific basis for designing more efficient bulletproof materials.

(3) Improvement of manufacturing process

Advanced manufacturing processes, such as 3D printing technology, also provide new possibilities for the production of bulletproof equipment. 3D printing technology can accurately control the structure and morphology of materials according to design requirements, and produce complex structures that are difficult to achieve with traditional processes. For example, the porous ceramic materials manufactured by 3D printing technology not only reduce weight but also improve bulletproof performance.

4.Application fields of bullet proof materials

(1) Military and law enforcement

Bullet proof materials are most widely used in the military and law enforcement fields, including bulletproof vests, bulletproof helmets, bulletproof vehicles, etc. These equipment can effectively protect personnel from bullets and explosives and improve the safety of combat and mission execution.

(2) Security protection

In the civilian field, bulletproof materials are used for bulletproof glass in places such as banks and jewelry stores, as well as bulletproof equipment for private security personnel. In addition, with the increase in terrorism and violent incidents, the application of bulletproof equipment in public safety is becoming more and more extensive.

(3) Aerospace

In the aerospace field, bulletproof materials are used to manufacture key parts of aircraft, such as cockpits and important systems to deal with possible ground fire threats. In addition, the protection of spacecraft also relies on high-performance bulletproof materials to resist the impact of space debris and micrometeorites. For example, the outer shell of the space shuttle uses multi-layer composite materials to effectively improve the protection capability.

5.Challenges and future development trends

(1) Balance between lightweight and high performance

One of the future development trends of bullet proof materials is to achieve a balance between lightweight and high performance. With the advancement of materials science and manufacturing technology, it is possible to develop lighter and stronger bullet proof materials. This can not only improve the comfort and mobility of the wearer, but also reduce the transportation and logistical burden of the equipment.

(2) Functional integration

In the future, bullet proof materials will tend to be functionally integrated, that is, while providing bulletproof functions, they will integrate other functions such as stealth, fire resistance, and chemical corrosion resistance. This will greatly improve the comprehensive performance and adaptability of equipment.

(3) Environmental adaptability and durability

Improving the adaptability and durability of bulletproof materials under different environmental conditions is also an important development direction. Whether in extreme climatic conditions or complex battlefield environments, bulletproof equipment needs to maintain stable performance.

(4) Cost and sustainability

Reducing the production cost of bullet proof materials and improving their sustainability is another key to future development. This goal can be achieved by optimizing production processes and using renewable resources. For example, using bio-based and recyclable materials to manufacture bulletproof equipment can not only reduce costs, but also reduce the impact on the environment.

6.Summary

The evolution of bullet proof materials is a history of scientific and technological innovation. With the continuous advancement of materials science and the optimization of production processes, future bullet proof materials will be lighter, more comfortable and more protective. They will continue to play an irreplaceable role in protecting human life and safety.

What do you think?

[…] made of need to have excellent protective properties, durability and comfort. The following are the main crafting materials of SWAT […]