Billet Aluminum Knowledge Encyclopedia: Classification, Production and Application Guide

Billet aluminum is an important raw material for the aluminum processing industry. It has various types, exquisite production technology and a wide range of applications. This article will provide you with an encyclopedia of aluminum billet knowledge, from classification, production to application, to fully analyze the mystery of aluminum billet, to help you better understand and use this high-quality material.

1.Definition and classification of billet aluminum

Billet aluminum refers to the raw material before aluminum processing, which is made after preliminary extraction and refining. It is an important basic material for aluminum processing companies to carry out subsequent processing and manufacture of aluminum products. It has various classifications, and different categories have their own characteristics in performance and application, which can meet the diverse needs of different industries for aluminum materials. The following is its specific classification:

(1) Classification by production process

1) Cast aluminum billet:

Aluminum billets produced by casting process are easy to form and low cost, and are suitable for the production of aluminum products with complex shapes and small batches. Common cast aluminum billets include aluminum alloy ingots and castings.

2) Deformed aluminum billet:

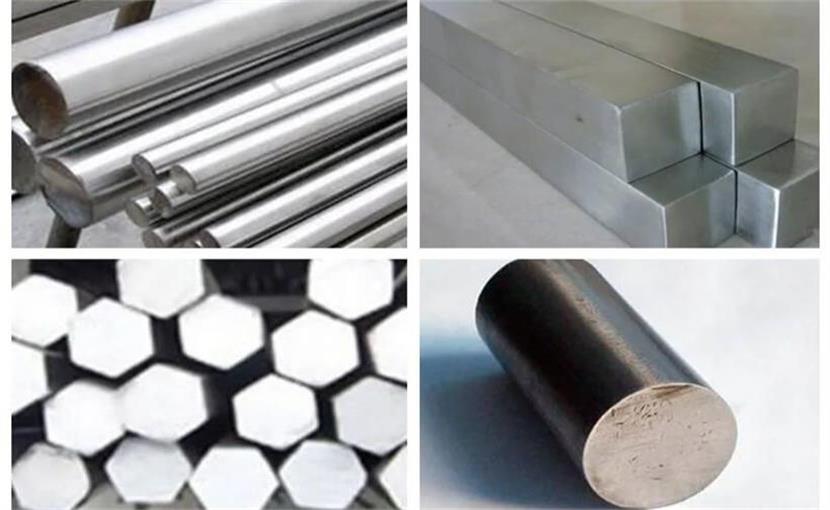

Aluminum billets made by plastic deformation processing (such as rolling, extrusion, forging, etc.) have high strength and good processing performance. Deformed aluminum billets can be further divided into plates, strips, foils, pipes, bars, profiles, etc., and are widely used in construction, aerospace, automobile manufacturing and other fields.

(2) Classification by alloy composition

1) Pure aluminum billet:

The main component is aluminum, with extremely low impurity content, good electrical conductivity, thermal conductivity and corrosion resistance, but relatively low strength. Pure aluminum billets are mainly used to make wires and cables, radiators, etc.

2) Aluminum alloy billets:

The alloy material formed by adding other elements (such as copper, magnesium, silicon, zinc, etc.) to pure aluminum has higher strength, hardness and other special properties. There are many types of aluminum alloy billets, the most common ones are aluminum-copper alloy, aluminum-magnesium alloy, aluminum-magnesium-silicon alloy, etc. Different types of aluminum alloy billets are suitable for different application scenarios.

For example, aluminum-copper alloys have high strength and are often used in the aerospace field; aluminum-magnesium alloys have low density and high strength and are widely used in automobile manufacturing and rail transportation.

(3) Classification by state

1) Hard aluminum billet:

Aluminum billets that have been cold-processed have high hardness but low plasticity.

2) Soft aluminum billets:

Aluminum billets that have not been cold-processed or properly heat-treated have good plasticity and are easy to process and form.

2.Production process of billet aluminum

The production process of aluminum billets mainly includes two key stages: casting and rolling. These two stages determine the quality and final performance of aluminum billets. The following is a detailed description of these two processes:

(1) Casting process of billet aluminum

1) Raw material preparation and smelting:

First, the aluminum ingots and intermediate alloys are inspected for appearance and chemical composition analysis to ensure that the raw materials meet the standards. Then, various raw materials are weighed according to the batching calculation results and added to the furnace in sequence for smelting. The easily oxidized and low-melting-point charge should be added last to reduce burnout.

2) Pre-furnace testing and composition adjustment:

After the alloy is melted evenly, sampling and testing are carried out to check whether the chemical composition meets the technical standards. If the chemical composition is found to be unsatisfactory, adjustments need to be made to ensure that it meets the technical standards.

3) Refining and modification:

After the chemical composition is qualified, a refining agent is used to remove the gas and solid particles in the alloy. Subsequently, a refiner and a modifier are added to improve the mechanical properties and mechanical cutting performance of the alloy.

4) Casting:

The treated aluminum alloy liquid is cast into ingots. Common casting methods include pressure casting, gravity casting and extrusion casting. Pressure casting is suitable for mass production, while gravity casting and extrusion casting are more suitable for complex shapes and small batch production.

5) Cooling and inspection before storage:

After casting, the aluminum billet needs to be cooled and inspected for chemical composition, gas content, inclusions, mechanical properties and appearance. Qualified aluminum billets are stored as qualified products.

(2) Rolling process of billet aluminum

1) Ingot preparation:

Surface treatment of qualified aluminum ingots to remove oxide scale and impurities to ensure smooth rolling process.

2) Heating:

Heat the aluminum ingot to an appropriate temperature, generally between 400-550°C, to reduce the deformation resistance of the material and improve plasticity.

3) Rough rolling:

Preliminary rolling of the heated billet aluminum on the rough rolling mill with a large reduction in order to quickly reduce the thickness of the billet aluminum and improve production efficiency.

4) Finishing rolling:

After rough rolling, the billet aluminum enters the finishing mill for further rolling. The reduction in the finishing process is small to ensure the thickness accuracy and surface quality of the billet aluminum.

5) Cooling and coiling:

The billet aluminum after rolling needs to be cooled to prevent oxidation and deformation. The cooled billet aluminum is coiled for subsequent processing and use.

6) Final inspection:

The mechanical properties, dimensional accuracy and surface quality of the rolled aluminum billet are inspected to ensure that the product meets user needs and quality standards.

3.Is the strength of the aluminum billet high? How to improve its strength?

The strength of the aluminum billet is relatively high. Aluminum has a high specific strength, that is, its strength is relatively high relative to its density. The strength of the aluminum billet is affected by many factors. The following is a point-by-point analysis of the strength of the aluminum billet from different angles:

(1) Alloy composition:

The strength of the aluminum billet is closely related to its alloy composition. The strength of pure aluminum is relatively low, but the strength of aluminum alloys formed by adding elements such as copper, magnesium, and zinc can be significantly improved. For example, 7075 aluminum alloy is often used in the aerospace field because of its extremely high strength.

(2) Heat treatment process:

The heat treatment process of the aluminum billet has an important influence on its strength. The mechanical properties of the aluminum billet can be significantly improved through solution treatment and aging treatment. Appropriate heat treatment can make the strengthening phase in the aluminum alloy precipitate uniformly, thereby enhancing the strength of the material.

(3) Processing technology:

The processing technology of aluminum billets will also affect their final strength. Cold processing such as cold rolling and cold drawing can produce a work hardening effect on aluminum billets, thereby improving their strength. However, excessive cold processing may cause the material to become brittle.

(4) Grain structure:

Refined grain structure helps to improve the strength of aluminum billets. By controlling the casting and heat treatment processes, the grains can be refined and the comprehensive mechanical properties of aluminum billets can be improved.

(5) Internal defects:

Internal defects in aluminum billets such as pores and inclusions will reduce their strength. Therefore, during the production process, it is necessary to strictly control the process parameters, reduce internal defects, and improve the density and strength of the material.

Summary:

In summary, the strength of aluminum billets can be significantly improved through reasonable alloy composition design, heat treatment process, processing technology and control of internal defects, thereby meeting the needs of different application fields.

4.Which is stronger, billet aluminum or forged aluminum?

In the application of aluminum products, aluminum billets and forged aluminum are two common material forms. As for the question of which of the two is stronger, it is necessary to discuss their manufacturing processes and characteristics.

Billet aluminum usually refers to the original aluminum material obtained through smelting, casting and other processes. Its internal structure is relatively loose, the grains are coarse, and the mechanical properties are relatively weak. Although aluminum billet has good plasticity, it performs generally in terms of strength and hardness, and is prone to deformation or fracture when subjected to external forces.

In contrast, forged aluminum has undergone forging processing. Forging is a process in which an external force is applied to a metal to cause plastic deformation, thereby improving its internal structure. After forging, the grains of aluminum are refined, and internal defects are reduced, so that the strength, hardness and toughness of the material are significantly improved.

Therefore, forged aluminum performs better in mechanical properties, can withstand greater external forces without failure, and is widely used in occasions with high material performance requirements, such as aerospace, automobile manufacturing and other fields.

Overall, forged aluminum is stronger than billet aluminum. Its performance in strength, hardness and toughness is better than that of aluminum billet. However, the specific choice of material still needs to be determined according to the actual application scenario and needs.

5.Application fields of billet aluminum

(1) Construction field:

Aluminum billets are widely used in the construction field, mainly for making doors and windows, curtain walls, ceilings, partitions and building frames. Billet aluminum products are not only beautiful and durable, but also have excellent sound insulation, heat insulation and fire resistance, which greatly improves the service life and beauty of the building.

(2) Transportation:

In the transportation field, aluminum billets are widely used in the manufacture of automobiles, trains and ships. The lightweight characteristics of aluminum billets help to reduce the overall weight of vehicles, improve fuel economy and operating efficiency, and reduce carbon dioxide emissions, which is in line with the development concept of modern green transportation.

(3) Electronics industry:

With the development of electronic products, the application of aluminum billets in the electronics field is becoming more and more important. The good heat dissipation performance of aluminum billets makes it an ideal material for manufacturing the shells of smartphones, tablets, laptops, etc. In addition, aluminum billets are also used to manufacture frames and heat sinks for products such as televisions and LED lamps.

(4) Packaging industry:

The application of aluminum billets in the packaging industry is mainly reflected in food, beverage and pharmaceutical packaging. Aluminum foil packaging has excellent sealing, corrosion resistance and heat preservation properties, which can effectively extend the shelf life of products. For example, aluminum cans play an important role in beverage packaging.

(5) Mechanical manufacturing:

Aluminum billets are used in the field of mechanical manufacturing to produce various mechanical equipment and parts, such as conveyor belts, rails, robotic arms, etc. The lightweight and high strength of aluminum billets help improve the performance and service life of mechanical equipment, while simplifying the installation and maintenance process.

(6) Aerospace:

Due to its light weight, high strength and good forming and processing properties, aluminum billets are also used in the aerospace field. They are usually used as structural materials for aircraft and spacecraft, such as skins, frames, fuel tanks, etc., which help improve the fuel efficiency and load capacity of aircraft.

6.Summary

As an important industrial material, aluminum billets are widely used in modern industry. Through continuous technological innovation and application expansion, billet aluminum will continue to play an important role in many industries, especially in the fields of lightweight, corrosion resistance and high strength requirements.