Annealing stainless steel: analysis of its material performance

Annealing stainless steel is a crucial part of stainless steel material processing and has a profound impact on the material’s performance. This paper aims to explore the specific effects of annealing stainless steel on its material structure and performance and its related applications, in order to provide a theoretical basis for the performance optimization of stainless steel materials in practical applications.

1.Definition of annealing and its importance in stainless steel processing

Annealing is a heat treatment process that involves heating the material to a specific temperature and holding it for a period of time, followed by slow cooling. This process is crucial in stainless steel processing because annealing stainless steel can improve the material’s microstructure and improve its mechanical properties, such as ductility and toughness. In addition, annealing can also reduce the material’s internal stress, which is critical to preventing cracks or other forms of damage during use.

2.Basic characteristics and application areas of stainless steel

Stainless steel is a highly corrosion-resistant alloy steel that mainly contains chromium and sometimes other elements such as nickel and molybdenum. The corrosion resistance of this material makes it widely used in many fields, including construction, automobile manufacturing, medical devices, and food processing equipment.

There are many types of stainless steel, and each type of stainless steel has its specific properties and application scenarios. For example, austenitic stainless steel is widely used in chemical equipment and food processing equipment due to its good weldability and corrosion resistance; martensitic stainless steel is often used to manufacture knives and medical devices due to its high strength and hardness.

3.The influence of annealing stainless steel on its material structure and properties

Annealing is an important heat treatment process that can change the microstructure and mechanical properties of metal materials through heating, insulation and cooling processes. The following are the main effects of annealing stainless steel on its material structure and properties:

(1) Changes in microstructure

1) Elimination of work hardening:

During the cold working process, stainless steel will produce work hardening, which is manifested as increased dislocation density and severe lattice distortion. Annealing can effectively eliminate these dislocations, make the structure uniform, soften the material, and restore plasticity.

2) Grain growth:

During the annealing process of stainless steel, the grains of stainless steel will undergo a recrystallization process and gradually grow. Appropriate annealing temperature and time can optimize the grain size distribution and improve the comprehensive performance of the material. Please note that too high a temperature or too long a time may cause grain coarsening, which in turn reduces the plasticity and toughness of the material.

3) Solid solution and decomposition of precipitates:

Carbides and other precipitates in stainless steel will re-dissolve in the matrix at high temperatures. Rapid cooling can prevent them from re-precipitating and improve intergranular corrosion resistance. However, improper cooling rate may lead to the re-precipitation of precipitates, affecting the corrosion resistance of the material.

.

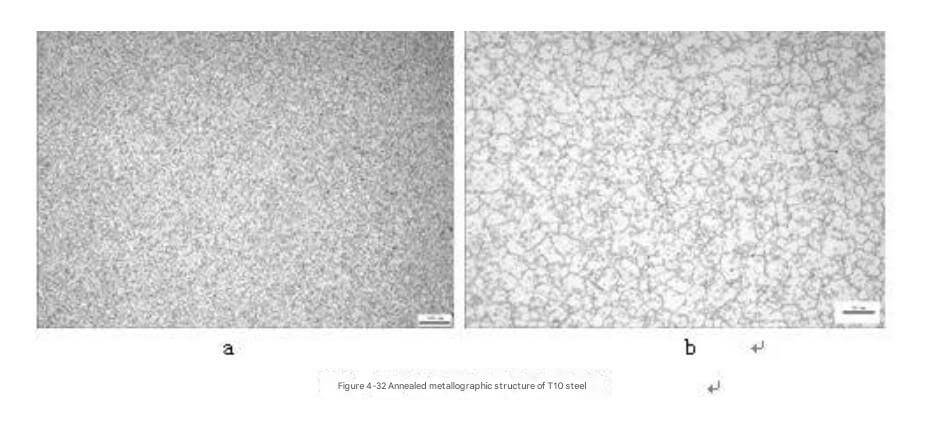

Microstructure changes of stainless steel after annealing

.

(2) Changes in mechanical properties

1) Strength and hardness:

Annealing stainless steel usually leads to a decrease in the tensile strength and hardness of stainless steel, while increasing the elongation and plasticity. This is because the work hardening is eliminated, the dislocation density is reduced, and the deformation resistance of the material is reduced.

2) Plastic strain ratio (r value):

The r value is an important parameter for evaluating the deep drawing performance of metal sheets. During the annealing process, the texture of the sheet is developed, the r value is increased, the material’s resistance to thickness thinning is enhanced, and the deep drawing performance is improved.

3) Yield strength:

Annealing below the recrystallization temperature will significantly reduce the yield strength; annealing above the recrystallization start temperature will increase the yield strength and the hardness will tend to be stable.

(3) Changes in corrosion resistance

1) Intergranular corrosion:

Long-term heating of stainless steel at certain temperatures may lead to chromium depletion at the grain boundaries, thus causing intergranular corrosion. Annealing can effectively prevent the occurrence of intergranular corrosion and improve the corrosion resistance of the material by dissolving carbides and rapidly cooling.

2) Sensitization phenomenon:

When heated for a long time in the temperature range of 500-850℃, stainless steel will undergo sensitization, resulting in a decrease in corrosion resistance. A reasonable annealing stainless steel process should avoid staying in this temperature range for too long.

(4) Influence of other properties

1) Internal stress elimination:

Annealing stainless steel can effectively eliminate residual stress inside the material, reduce deformation and cracking, and improve dimensional stability.

2) Improved processing performance:

After annealing, the hardness of stainless steel is reduced, the plasticity is increased, and the machinability is improved, which is conducive to subsequent cold processing and forming operations.

.

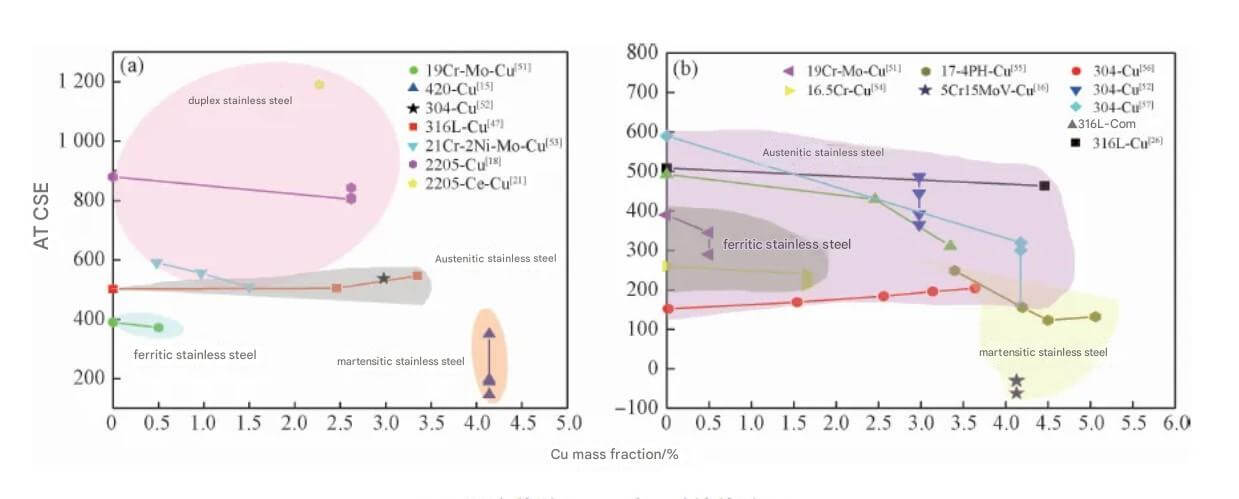

Pitting potential of Cu-containing antibacterial stainless steel after annealing

.

4.Types of common annealed stainless steel and their annealing behavior

(1) Austenitic stainless steel

Austenitic stainless steel mainly improves its plasticity and toughness by eliminating internal stress during annealing. Low temperature annealing (480-650°C) or high temperature annealing (1010-1120°C) is usually used. The former is suitable for stress relief, while the latter is used for complete austenitization. After high temperature annealing, stainless steel needs to be slowly cooled to avoid stress corrosion.

(2) Ferritic stainless steel

The annealing of ferritic stainless steel is mainly to adjust its microstructure to improve plasticity and toughness. The common annealing temperature is 750-850°C, and then slowly cooled after insulation. This treatment helps to reduce the stress concentration generated during cold working.

(3) Martensitic stainless steel

The annealing of martensitic stainless steel includes softening annealing and stress relief annealing. Softening annealing is generally carried out at 650-750°C to reduce hardness and improve cutting performance. Stress relief annealing is carried out at 300-500°C to reduce residual stress and prevent deformation and cracking.

(4) Duplex stainless steel

Duplex stainless steel has the characteristics of both austenitic and ferritic stainless steels, and the annealing treatment needs to balance the properties of both. Usually, high temperature annealing is carried out at 950-1050°C, and then rapid cooling is carried out after heat preservation to obtain good mechanical properties and corrosion resistance.

5.Application fields of annealing stainless steel

Stainless steel is widely used in various fields due to its excellent corrosion resistance, strength and aesthetics. After annealing, this material not only reduces its hardness, improves its plasticity and toughness, but also eliminates internal stress, thereby further expanding its application range. The following are the main application fields of stainless steel after annealing:

(1) Construction and decoration industry:

Annealing stainless steel is used in the construction field to manufacture building materials such as doors, windows, guardrails, and roof panels. Its superior corrosion resistance and aesthetics make it the preferred material for high-end buildings. In addition, stainless steel decorative panels, sculptures, etc. are also widely used in indoor and outdoor decoration.

(2) Medical device industry:

Due to the characteristics of stainless steel such as non-toxic, odorless, and antibacterial, annealing stainless steel is widely used in the manufacture of medical devices such as surgical instruments, medical needles, artificial bones, etc. These devices require high cleanliness and corrosion resistance to ensure medical safety.

(3) Food processing and packaging industry:

Annealing stainless steel is indispensable in the manufacture of food processing equipment (such as blenders, heaters) and packaging containers (such as cans, food cans). Its corrosion resistance and easy cleaning properties ensure food hygiene and safety.

(4) Chemical and energy industry:

In the chemical and energy fields, annealing stainless steel is used to manufacture equipment in high temperature and high pressure environments, such as heat exchangers, condensers, nuclear power equipment and solar power generation equipment. Its high temperature resistance and corrosion resistance ensure the long-term and stable operation of the equipment.

(5) Aerospace and marine engineering:

These fields have extremely high requirements for the strength and corrosion resistance of materials. Annealing stainless steel is used to manufacture aviation engine parts, spacecraft structures and key components of marine platforms to ensure reliability and safety in extreme environments.

(6) Electronic products and light industry:

Annealing stainless steel is widely used in the manufacture of electronic product shells (such as mobile phones and tablets) and light industry (such as tools, musical instruments, and auto parts). Its beautiful, durable and corrosion-resistant characteristics meet the high standards of modern industry.

6.Case analysis of annealing stainless steel in practical applications

(1) Processing and microstructural evolution of 436 and 432 stainless steels

436 and 432 stainless steels are widely used in automotive exhaust systems due to their excellent corrosion resistance and formability. The microstructural evolution of these materials during the annealing process has a decisive influence on the performance of the final product.

For example, during the rolling and annealing process of 436 stainless steel, spherical or equiaxed recrystallized grains will form on the surface layer, which helps to improve the ductility and toughness of the material. During further cold rolling and annealing, the changes in texture and microstructure will directly affect the deep drawing performance and surface quality of the material.

(2) Performance improvement of 304 stainless steel after annealing

304 stainless steel is one of the most widely used stainless steels, and its performance improvement after annealing is particularly significant. Annealing can significantly improve the ductility and toughness of 304 stainless steel, which is crucial for its application in the food, construction and automotive industries.

7.Summary

The analysis in this article shows that annealing has a significant impact on the performance of stainless steel materials. Reasonable annealing process of stainless steel can effectively improve the microstructure of stainless steel, enhance its mechanical properties and corrosion resistance, and thus expand its application range.

What do you think?

[…] quenching process is an important means to improve the hardness, strength and wear resistance of stainless steel workpieces. Liquid argon, as a cooling medium, shows unique advantages in stainless steel quenching. The […]