Amorphous transformer compared to traditional transformers: a full range of comparative analysis

The topic of amorphous transformer compared to conventional transformers has been of great interest in the field of power equipment.There are significant differences between the two types of transformers in terms of performance, energy efficiency and environmental impact. With the growing global demand for energy saving and green power systems, the advantages of amorphous transformers are becoming more and more prominent. This paper will comprehensively compare and analyze amorphous transformers and traditional transformers, revealing their unique advantages.

1.Overview of transformer related knowledge

(1) the importance of the transformer

Transformer as one of the most critical equipment in the power system, its main function is to realize the conversion of voltage through the principle of electromagnetic induction, so as to play an important role in the process of power transmission and distribution. Transformer not only affects the stability and efficiency of the power system, but also directly relates to the rational utilization of power resources and the level of energy consumption.

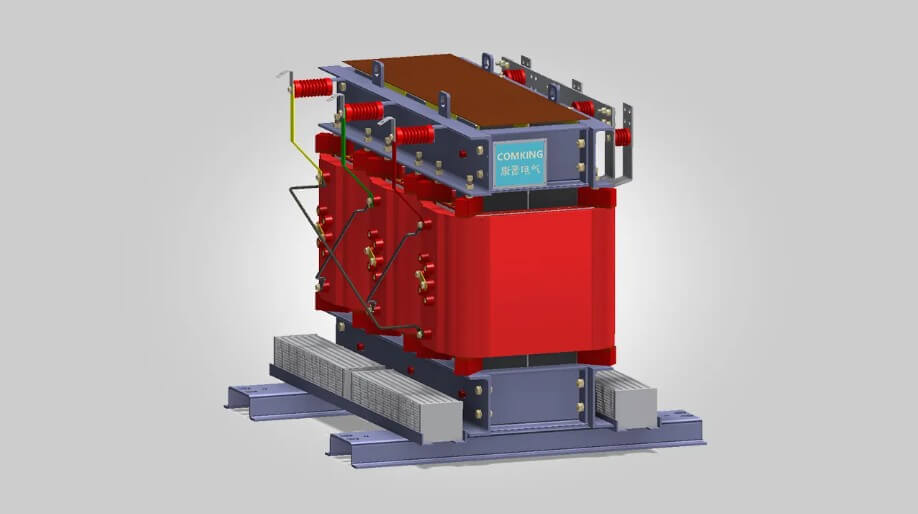

(2) the introduction of amorphous transformer

The emergence of amorphous transformer is a major innovation in transformer technology. This transformer uses amorphous material as the iron core, its unique physical and chemical properties make amorphous transformer in energy saving and environmental protection outstanding performance, and gradually become a strong alternative to the traditional transformer.

2.Amorphous transformer working principle and features

(1) working principle

Amorphous transformer using electromagnetic induction principle. Its core is made of amorphous alloy material, this material has a disordered atomic arrangement, than the traditional silicon steel core no-load loss is 60% -80% lower. When working, the primary side of the winding into the alternating current generates alternating magnetic field, in the secondary side of the winding induced voltage, so as to realize the transmission of electric energy.

(2) amorphous transformer main features:

1) low loss:

Amorphous coercivity is much smaller than the traditional silicon steel sheet, its hysteresis return line enveloped by the area is much smaller than the cold rolled silicon steel sheet, so that the amorphous transformer no-load loss than the same capacity of the S11 type reduced by about 75%.

2) high efficiency:

Due to the low loss, amorphous transformer operation efficiency is higher, can be more effective conversion and transmission of electric energy.

3) Strong corrosion resistance:

Amorphous materials have good corrosion resistance, improving the service life of the transformer.

4) Good stability:

Amorphous transformer structure design is reasonable, can be in a variety of environments stable operation, and low maintenance needs.

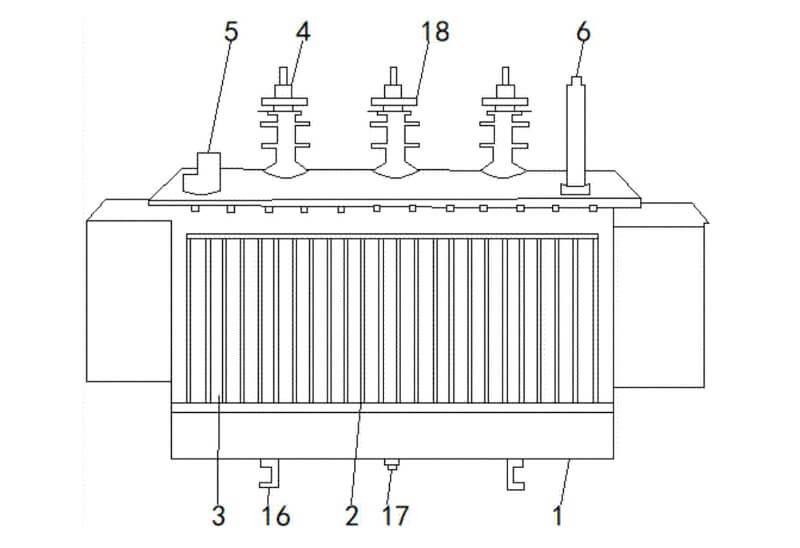

3.The working principle and characteristics of the traditional transformer

(1) working principle

Traditional transformers mainly rely on the principle of electromagnetic induction for voltage conversion. Alternating current through the primary coil generates an alternating magnetic field, which is transmitted through the iron core and induces a voltage in the secondary coil, thus realizing the voltage increase or decrease.

(2) Main features of traditional transformers:

1) simple manufacturing:

Traditional transformer manufacturing process is relatively simple, mature technology, easy to mass production.

2) low cost:

Due to the low cost of manufacturing materials and processes, the initial investment cost of traditional transformers is relatively low.

3) Higher loss:

Compared with the traditional silicon steel sheet transformer, amorphous alloy transformer no-load loss can be reduced by 70~80%, no-load current can be reduced by about 50%, so the operation efficiency of the traditional transformer is lower, especially under light load conditions.

4) Maintenance requirements:

Traditional transformers require regular maintenance to ensure their long-term stable operation.

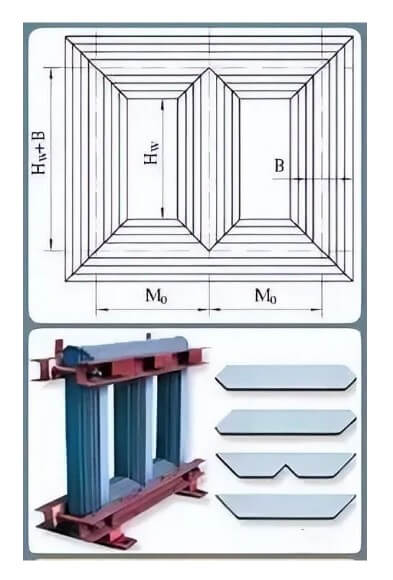

4.amorphous transformer compared to traditional silicon steel transformer: material comparison

(1) Amorphous transformer

Amorphous transformers use iron-based amorphous alloy as the core material. This material is made by rapid cooling technology, the atomic arrangement is random and disordered, showing an amorphous structure. Iron-based amorphous alloys are characterized by high permeability, low coercivity and low losses.

The saturation magnetic flux density of amorphous is relatively low, but its high resistivity and small magnetic crystal anisotropy make its loss under the same magnetic flux density much lower than that of silicon steel materials.

(2) Traditional silicon steel transformer

Traditional silicon steel transformers use crystalline silicon steel sheet as the core material. Silicon steel sheet has good magnetic properties through special treatment, but compared to amorphous, its permeability is lower, coercivity and losses are higher.

Silicon steel sheet saturation flux density is higher, suitable for high flux density application scenarios, but with the larger iron loss and eddy current loss.

5.Amorphous transformer compared to traditional silicon steel transformers: structure and design differences

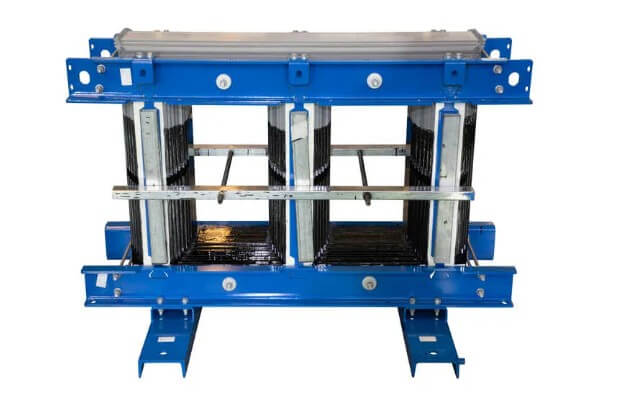

(1) Amorphous transformer

The core of an amorphous transformer usually adopts a coiled structure, which is made of amorphous strip continuously coiled. This structure reduces seams and magnetoresistance, further reducing losses.

Due to the characteristics of amorphous material, its core filling factor is relatively low, usually between 0.84 and 0.86.

(2) Conventional silicon steel transformers

Silicon steel transformer core generally adopts laminated structure, made of multiple silicon steel sheets laminated together. This structure has more seams and magnetoresistance, resulting in relatively high losses.

Silicon steel sheet filling coefficient is high, usually above 0.95, making the overall structure of the transformer more compact.

6.amorphous transformer compared to traditional silicon steel transformer: performance comparison

(1) loss

Amorphous transformer no-load loss and load loss are much lower than traditional silicon steel transformer. No-load loss can be reduced by more than 70%, load loss can be reduced by about 80%.

Amorphous transformer in the power supply waveform distortion resistance is also better than the silicon steel transformer, in the case of larger distortion in the power grid, the loss increase is smaller.

(2) efficiency

Due to low loss, amorphous transformer in the operation process is more efficient, can significantly reduce power loss, improve the overall energy efficiency of the power system.

Amorphous transformer in light load efficiency advantage is especially obvious, more suitable for load fluctuation application scenarios.

(3) noise

Amorphous magnetostriction coefficient is large, resulting in amorphous alloy transformer noise is relatively high, usually 3 to 5 dB larger than the noise of silicon steel transformer.

However, with the progress of technology, amorphous transformer noise problem is gradually being improved.

7.Amorphous transformer compared to traditional silicon steel transformer: economy and environmental protection

(1) initial investment

The manufacturing cost of amorphous transformers is relatively high, mainly due to the high price of amorphous materials and the relatively complex production process.

However, amorphous transformers have significant energy-saving effects and can recover costs in a relatively short period of time by saving electricity.

(2) Operating costs

Amorphous transformer due to low loss, the operation of the process of electricity consumption is much lower than silicon steel transformer, can significantly reduce the user’s electricity expenditure.

According to the calculation, amorphous transformer and secondary energy-efficient transformer, compared with the payback period of about 4 years; compared with the primary energy-efficient transformer, the payback period of about 8 years.

(3) environmental protection

Amorphous transformer in the operation process produces no-load loss and load loss is lower, reducing energy consumption and carbon emissions, more in line with environmental requirements.

Amorphous material production process compared to silicon steel sheet production, lower energy consumption, less pollution, but also more environmentally friendly.

8.Summary

Amorphous transformers are superior to traditional silicon steel transformers in terms of material, structure and design and performance. Its low loss, long life and significant energy saving effect, make it in energy saving and environmental protection outstanding. With the “energy saving and consumption reduction” in-depth promotion, amorphous transformer will have a broad application prospects.