Amorphous alloy military: application areas and its performance advantages

Amorphous alloy military lightweight and high performance is an important direction in the development of modern military technology. Amorphous alloy with its high strength, high hardness and good toughness, to create a stronger, lighter military equipment provides an ideal material choice. In this paper, we will discuss in depth the specific application places of amorphous alloys military and application advantage analysis.

1.The basic introduction of amorphous alloys

(1) the definition and structural characteristics of amorphous alloys

Amorphous alloy, also known as metal glass, is a special material with a disordered atomic structure. This material forms an amorphous solid state by rapidly cooling the molten state of a metal or alloy so that its atoms are too late to form a conventional crystal structure. This disordered structure gives amorphous alloys many unique physical and chemical properties, so that they have a wide range of applications in the military field.

(2) amorphous alloy military: application history

1) Early exploration stage (1970s-1980s)

Scientists began to study the special properties of amorphous alloys, such as high strength, high hardness and excellent corrosion resistance.

Initial attempts to apply amorphous alloys in the military field, such as the production of amorphous alloys military lightweight weapons components.

2) technological breakthroughs and application expansion (1990s)

Amorphous alloy preparation technology breakthroughs, production costs have been significantly reduced, the popularization of the application has become possible.

The military field began to apply amorphous alloy on a large scale, covering ammunition, armored vehicles, aerospace and other aspects.

3) In-depth research and development and performance optimization (the beginning of the 21st century to the present)

For different military needs, amorphous alloy composition and structure are optimized and designed to enhance their comprehensive performance.

Amorphous alloy military in the intelligent weapons and equipment, high-end protective equipment and other advanced military fields show great potential for application.

4) The future development trend

Amorphous alloy and other materials composite use will become the focus of research, is expected to develop new military materials with better performance.

The application of 3D printing technology will make amorphous alloy military parts manufacturing more flexible and efficient, to meet the military field of personalization, customization needs.

2.Amorphous alloy performance advantages

(1) high strength and toughness

Amorphous alloy has very high strength and toughness, its strength far exceeds the traditional crystalline materials. This characteristic makes amorphous alloys in withstand heavy loads and impact performance is excellent, very suitable for military and aerospace and other areas of material performance requirements are extremely high. For example, Fe-based amorphous alloys in the Fe-Si-B series of alloys, its low coercivity, high permeability, low production costs, good processing performance, resistivity is about three times that of silicon steel sheet, while the iron loss is only one-fourth of the orientation of silicon steel sheet, one-tenth of the non-orientation of silicon steel sheet, and thus has an important significance for energy saving and reduction of consumption.

(2) high hardness and wear resistance

The hardness of amorphous alloys is usually higher than that of many crystalline alloys, which makes them excellent in wear-resistant applications. For example, amorphous alloys have been widely used in the manufacture of highly wear-resistant audio-video magnetic heads. In addition, amorphous alloys are used in the manufacture of wear-resistant parts such as hydraulic cylinders and pistons in automobile engines, which can substantially increase their service life.

(3) Excellent magnetic properties

Some amorphous alloys have excellent magnetic properties, including high permeability, low coercivity and low core loss. These properties make amorphous alloys very useful in the manufacture of electronic equipment such as high-efficiency transformers and motors. For example, Fe-based amorphous alloys in the Fe-Si-B series of alloys, its low coercivity, high permeability, low production costs, good processing performance, the resistivity is about three times that of silicon steel sheet, while the iron loss is only one-fourth of the orientation of silicon steel sheet, one-tenth of the non-orientation of the silicon steel sheet, and thus is of great significance for energy saving and consumption reduction.

(4) corrosion resistance

Amorphous alloys in a variety of corrosive environments show good corrosion resistance, this is because their surface can form a uniform passivation film, effectively blocking the intrusion of corrosive substances. For example, the use of amorphous alloy resistance to a variety of media corrosion characteristics, can be used to prepare corrosion-resistant parts and components of large amorphous alloy materials, can significantly improve its service life.

3.Amorphous alloy military: specific application place analysis

(1) light weapons and ammunition

Amorphous alloy due to its high strength and good penetration, has been applied to the manufacture of firearms parts and bullet core. For example, the use of amorphous alloys in the manufacture of bullet cores can significantly improve the penetration and lethality of ammunition. In addition, amorphous alloy is also used in the manufacture of high wear-resistant audio-video heads, which are widely used in high-grade audio and video cameras.

(2) Armored vehicles and protective equipment

Amorphous alloy’s high hardness and lightness make it an ideal material for manufacturing composite armor. This material can not only effectively reduce the weight of armored vehicles, but also improve protection. For example, the current development of Zr-based amorphous alloy fracture toughness of up to 60Mpa.m1/2, has been found to be the most excellent armor-piercing bullet core material. At the same time the use of large amorphous alloys of high hardness characteristics can also become armor-piercing protective materials, such as armor, bulletproof undershirts and so on.

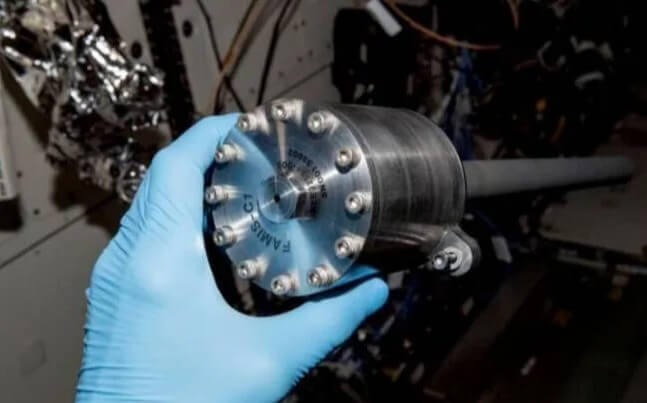

(3) Aerospace materials

Amorphous alloys of high specific strength and high specific stiffness make it in the aerospace field has important applications. For example, the use of large amorphous alloys of high specific strength, specific stiffness of the excellent mechanical properties, the manufacture of aerospace vehicles, the main frame, structural honing frame, bearings, mirror bracket and other structural materials, can be a large proportion of the weight reduction, which is equivalent to improve the thrust ratio of the aero-engine.

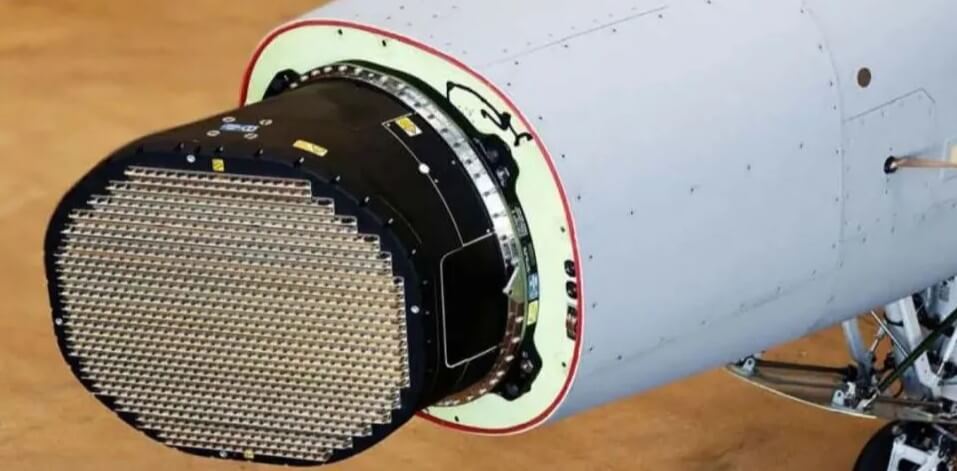

(4) Radar and communication equipment

Amorphous alloy’s excellent electromagnetic properties make its application in radar and communication equipment has great potential. For example, amorphous alloys can be used to manufacture high-efficiency antennas and sensors to improve the sensitivity and reliability of radar systems. In addition, amorphous alloys are also used to manufacture high-performance electronic components, such as transformers and motors, to improve the efficiency and stability of electronic equipment.

(5) Military cutting tools:

The high hardness and corrosion resistance of amorphous alloys make them very attractive in the manufacture of military knives. The use of amorphous alloys manufactured knives are not only sharp, but also in harsh environments for a long time to maintain stable performance, not easy to rust or damage. This is particularly important for the implementation of special tasks for military personnel.

4.Amorphous alloy military: application enhancement and advantage analysis

(1) Enhance equipment durability and lightweight:

Amorphous alloys have very high strength and hardness, applied to military equipment such as armored vehicles, protective clothing, etc., can significantly enhance the durability and protection capabilities, while its lower density, which helps to achieve equipment lightweight and improve troop mobility.

(2) Enhancement of weapon performance:

Amorphous alloy’s excellent magnetic properties make it used in electromagnetic weapons such as electromagnetic guns and other equipment, significantly improving the range and power of weapons. Its corrosion-resistant properties are also applicable to the manufacture of firearms and knives, to extend the service life of weapons and maintain good performance.

(3) Enhance the reliability of electronic equipment:

Amorphous alloys in the application of electronic devices, such as transformers, sensors, etc., can improve the efficiency and reliability of the equipment, to ensure that the military electronic equipment in harsh environments stable operation.

(4) Improve radar and communication systems:

Amorphous alloy’s good electromagnetic wave absorption properties help to reduce the signal scattering of radar systems, improve radar detection accuracy and stealth performance. In the communication system, the application of amorphous alloy helps to enhance the stability and confidentiality of signal transmission.

(5) Promote the development of military energy technology:

Amorphous alloys in solar panels and other energy conversion equipment, can improve the energy conversion efficiency for military bases and field operations to provide a more efficient energy supply, enhance the continuity of military operations and independence.

5.Amorphous alloy military: application challenge analysis

(1) processing difficulties:

Forming of amorphous alloys usually requires extremely fast cooling rates, which limits their size and shape. In addition, amorphous alloys of high hardness, traditional processing methods are difficult to apply, the development of new processing technology is costly and technically complex.

(2) Cost issues:

Currently, the production cost of amorphous alloys is high, mainly due to the complexity of their production process and low yield. This makes the cost of applying amorphous alloys in large-scale military equipment manufacturing difficult to bear.

(3) Performance consistency:

Due to the complexity of the preparation process of amorphous alloys, there may be differences in the performance of different batches of products, which is unacceptable in military applications that require a high degree of consistency and reliability.

(4) Insufficient theoretical research:

Although amorphous alloys have many excellent properties, the basic theoretical studies on their deformation mechanisms, fracture behavior and heat treatment effects are not yet perfect, which limits their in-depth application in the military field.

6.Summary

To summarize, amorphous alloys have broad prospects for military applications, and their excellent properties significantly improve the overall performance of military components. The current challenges mainly stem from the lack of theory and practice, but with the continuous progress of technology, it is predicted that the future amorphous alloy military will continue to develop in high-performance, environmentally friendly equipment.

What do you think?

[…] as the mid-20th century, scientists began to explore the application of amorphous metals in the military field, but due to technical and cost limitations, their application in tank manufacturing has not […]