Analysis of amorphous alloy bulletproof performance: in the end where is the power?

The significant advantages of amorphous alloy bulletproof performance for modern protection technology has brought a revolutionary breakthrough.As a material with a unique atomic structure, amorphous alloys show strength and toughness far beyond traditional alloys. In the field of ballistic protection, this means that lighter and more efficient protective equipment has become possible. This paper will analyze the amorphous alloy bulletproof performance and its advantages and applications.

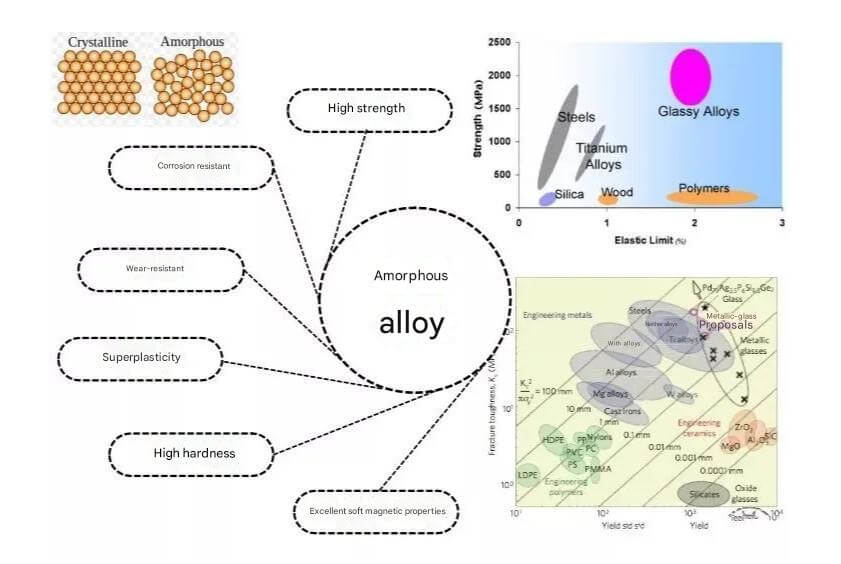

1.The basic concepts and characteristics of amorphous alloys

(1) the definition of amorphous alloy

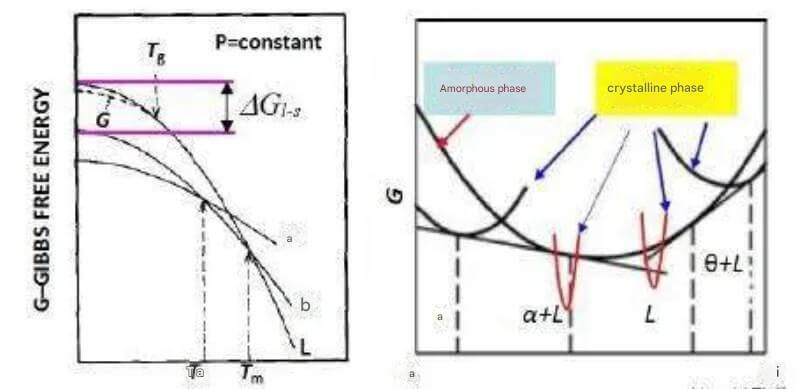

Amorphous alloy, also known as metal glass, is a kind of alloy in the solid state in which the atomic arrangement is topologically disordered. This material is formed by rapid cooling of a metallic liquid, which prevents the orderly arrangement of atoms, resulting in an amorphous structure that is different from the traditional crystal structure. This special structure of amorphous alloys gives them excellent mechanical and chemical properties, making them show great potential for application in many high-tech fields.

(2) Chemical Properties

The chemical properties of amorphous alloys are also remarkable, they usually have excellent corrosion resistance. Because of the amorphous structure of the absence of grain boundaries and other defects, these defects are often the starting point for corrosion, so amorphous alloys in harsh environments is more stable

(3) mechanical properties

Mechanical properties of amorphous alloys are excellent, they usually have high strength and hardness, while maintaining good elasticity. These characteristics make amorphous alloys can show excellent deformation resistance and resilience when subjected to external forces. According to research, the tensile strength of amorphous alloys is about three times that of conventional crystalline alloys, while the Young’s modulus is about 1/3. this means that amorphous alloys have higher elastic properties while maintaining high mechanical strength.

The mechanical properties of amorphous alloys are also characterized by their high toughness and impact resistance. Because there are no defects such as grain boundaries and dislocations in amorphous alloys, they are less prone to fracture and deformation when subjected to force. This makes amorphous alloys excel in withstanding heavy loads and impacts, which is very suitable for military and security fields. For example, bulletproof vests and helmets made of amorphous alloys are able to absorb and disperse the impact of bullets or fragments more effectively, providing a higher level of protection.

2.Amorphous alloy bulletproof performance analysis

(1) High strength and hardness

The high strength and hardness of amorphous alloy is its core advantage as a bulletproof material. Due to the disordered nature of its atomic arrangement, amorphous alloys are able to disperse and absorb energy more effectively when impacted by external forces, reducing the penetration of bullets or fragments. This characteristic allows amorphous alloys to demonstrate superior performance in safety and protective equipment such as bulletproof vests and bulletproof glass. Compared with traditional bulletproof materials, amorphous alloys are not only lighter, but also more effective in bulletproofing, and can provide users with a higher level of security protection.

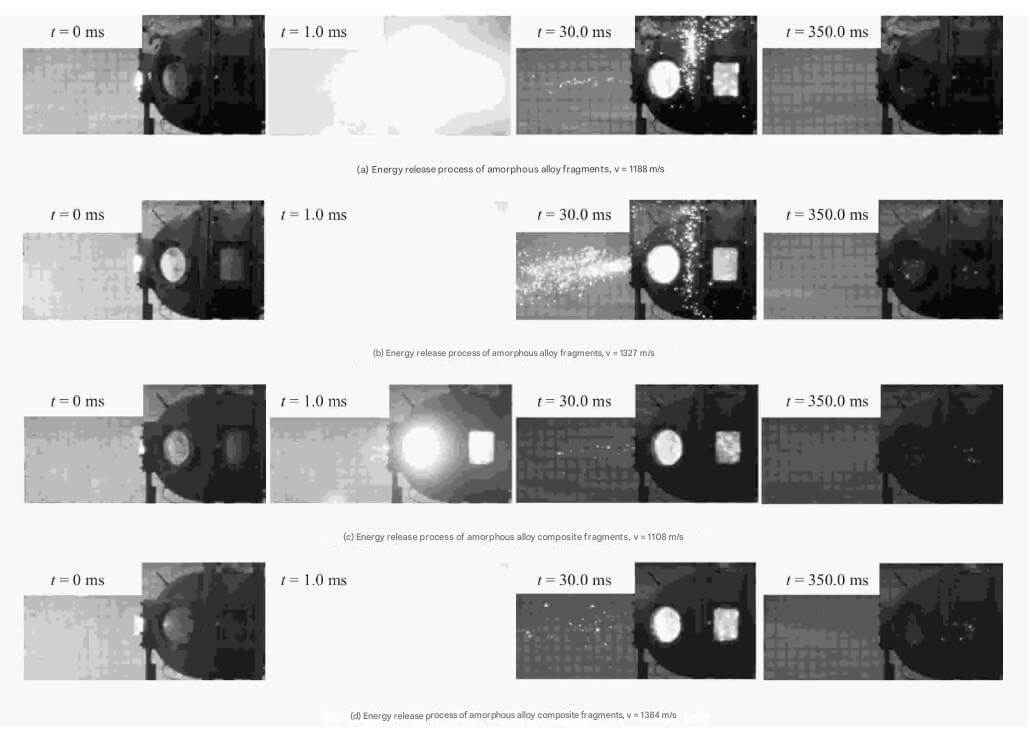

.

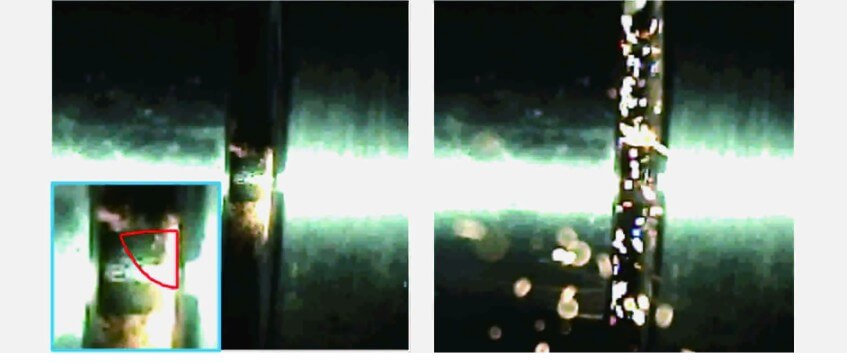

Energy changes of amorphous alloys when they encounter impact

.

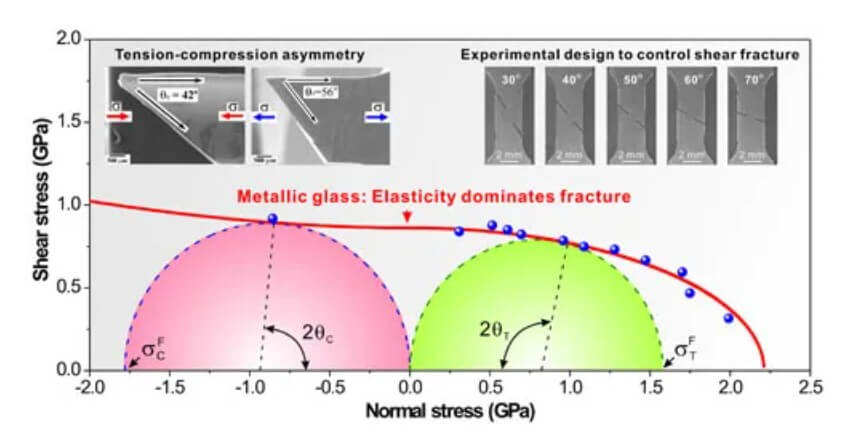

(2) Fracture Toughness

Fracture toughness refers to the ability of the material to resist fracture when subjected to impact. The fracture toughness of amorphous alloys is significantly higher than that of many traditional materials, which makes it particularly important in bulletproof applications. When impacted by a bullet, amorphous alloys are able to absorb more energy and reduce the likelihood of fragmentation and crack extension, thereby improving the overall stability and safety of the protective structure. This characteristic of amorphous alloy makes its application in the field of bulletproof broader prospects.

.

Fracture law and strength of amorphous alloys

.

(3) anti-fatigue and corrosion resistance

Amorphous alloy also has good anti-fatigue and corrosion resistance. In the long-term use process, bulletproof materials need to withstand repeated mechanical stress and environmental erosion, and amorphous alloy fatigue resistance ensures that its repeated loading and unloading conditions can still maintain stable performance. In addition, the corrosion resistance of amorphous alloys makes it possible to maintain stable performance in harsh environments, prolonging the service life of amorphous alloy ballistic protection equipment. These characteristics make the amorphous alloy in the field of bulletproof application has important practical significance.

(4) “self-sharpening” effect

Amorphous alloy in the deformation process will appear a unique “self-sharpening” effect, that is, the material in the deformation of the force, the surface hardness will increase, the formation of more sharp cutting edge. This effect makes amorphous alloys more effective in preventing bullets or sharp objects from penetrating in ballistic applications, improving protection. Studies have shown that the amorphous alloy “self-sharpening” effect is particularly obvious in high-speed impact conditions, which makes the amorphous alloy ballistic materials in the field of high-strength protection has a unique advantage.

3.Amorphous alloys in the application of bulletproof examples

(1) military field

In the military field, amorphous alloys have been used to manufacture high-performance bulletproof vests and bulletproof helmets. The lightweight and high ballistic performance of this material enables soldiers to obtain better protection on the battlefield while maintaining high mobility. For example, a bulletproof vest based on amorphous alloys can not only effectively defend against conventional firearms, but also to a certain extent against damage from explosive fragments. In addition, amorphous alloys are also used in the manufacture of protective armor for military vehicles to improve the vehicle’s ability to resist blows and protect the safety of vehicle occupants.

(2) Police equipment

In the police equipment, amorphous alloy bulletproof material is also widely used. Police officers face a variety of potential security threats when performing their duties, high-performance amorphous alloy bulletproof equipment is the key to ensure their safety. Amorphous alloys made of bulletproof vests and bulletproof shields, not only lighter weight, easy to carry and operate, and bulletproof effect is remarkable, can effectively resist the pistol and rifle shooting. In addition, amorphous alloy is also used in the manufacture of police vehicles protective armor, improve the safety performance of the vehicle, to protect the safety of the police in the car.

4.Challenges and limitations of amorphous alloy bulletproof performance

(1) cost issues

Despite the significant advantages of amorphous alloy bulletproof performance, but its production cost is relatively high. This is mainly because the manufacturing process of amorphous alloys requires precise temperature control and fast cooling rates, and these process requirements increase production costs. In addition, amorphous alloy processing and molding process is also relatively complex, requiring special equipment and technology, further pushing up the production cost. These factors limit the wide application of amorphous alloys in the field of bulletproof.

(2) processing difficulty

Amorphous alloys are difficult to process. Due to their high hardness and brittleness, conventional machining methods face challenges when dealing with amorphous alloys. For example, conventional machining methods such as cutting and drilling may result in rupture or damage to the material, affecting its performance. Therefore, the development of new machining techniques and technologies is an important direction for applied research on amorphous alloys. Studies have shown that the use of advanced technologies such as laser processing and EDM can effectively solve the processing challenges of amorphous alloys and improve the utilization of materials and production efficiency.

(3) Performance decay

Amorphous alloy in the long-term use of the process may appear performance attenuation. Especially in high temperature or repeated stress conditions, its structure may change, affecting the amorphous alloy bulletproof performance. Therefore, continuous research and development is necessary to improve the stability and durability of amorphous alloys. For example, by adding appropriate amount of alloying elements and optimizing the microstructure of the material, the thermal stability and fatigue resistance of amorphous alloys can be improved to extend their service life.

.

Energy release mechanism of Zr-based amorphous alloy failure under dynamic compression

.

5.Conclusion

(1) Advantages of amorphous alloy bulletproof performance

Amorphous alloy has excellent bulletproof performance, and its high strength, hardness and fracture toughness make it an ideal choice for bulletproof materials. In addition, the anti-fatigue and corrosion resistance of amorphous alloys also ensure their stability and reliability in long-term use. These properties make amorphous alloy bulletproof materials have a broad application prospect in military and police bulletproof equipment.

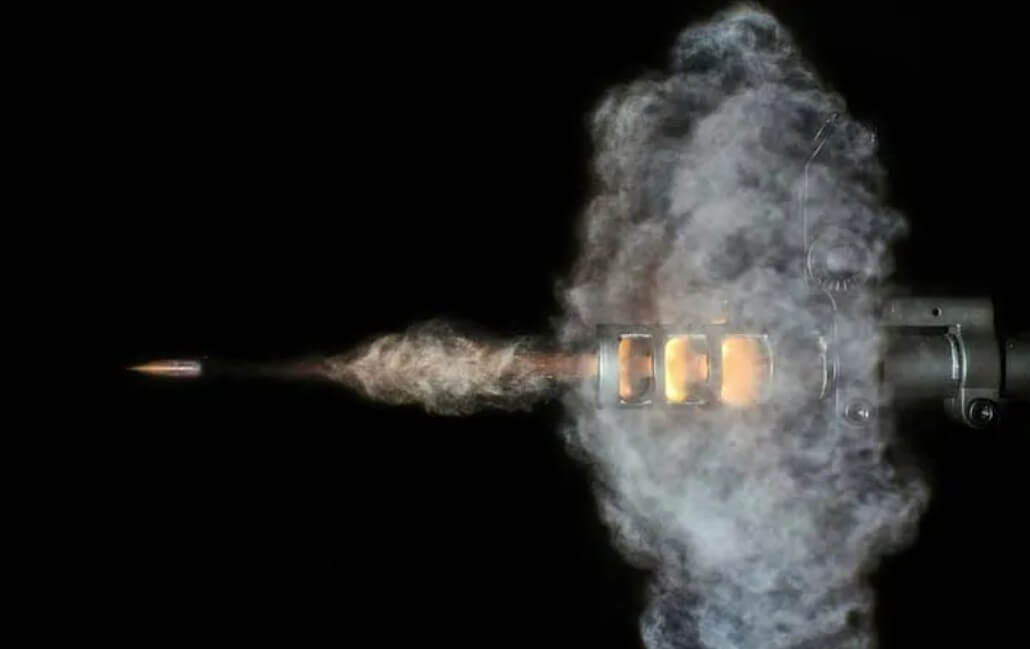

.

Performance comparison of amorphous and crystalline states under the same conditions

.

(2) Future research and improvement direction

Although this amorphous alloy bulletproof material shows significant advantages, problems such as cost, processing difficulty and performance degradation still need to be solved. Future research should focus on optimizing the manufacturing process of amorphous alloys, reducing the production cost, developing new processing technologies, and improving the performance stability of the material. In addition, exploring the composite use of amorphous alloys with other materials may also be an effective strategy to improve ballistic performance.

What do you think?

[…] (2) Armored vehicles and protective equipment […]

[…] weapons. The application of amorphous alloys provides new possibilities for lightweight and high-strength protection of tanks, meeting the new requirements of modern warfare for tank […]

[…] Bullet proof materials play a vital role in modern society. They not only protect military personnel from bullets, but are also widely used in law enforcement, security and civilian protection. Bullet proof materials are materials that can resist the invasion of bullets or fragments, such as glass fiber composites, aramid and ultra-high molecular weight polyethylene. They have the advantages of good anti-ballistic performance, light weight and convenient processing. […]

[…] bulletproof principle of armor mainly relies on the physical properties of the material to disperse and absorb impact […]

[…] utilize the high strength and hardness of amorphous materials to more effectively penetrate modern armor. Compared with traditional depleted uranium bullets, piercing bullet amorphous are not inferior in […]

[…] the best. These two materials have their own characteristics and are increasingly widely used in the field of bulletproof. So, which one is the best craftable bulletproof material? This article will make an in-depth […]