Aerospace Amorphous: A New Material for Space Exploration

Aerospace amorphous, as an important part of modern space technology, its importance cannot be overstated. These amorphous alloys not only have excellent properties such as high strength, high hardness, and high temperature resistance, but also can maintain stable performance in extreme environments, making them ideal for manufacturing key spacecraft components. In this paper, we will explore the basic concepts, classifications, properties of aerospace amorphous materials and their applications in aerospace engineering, revealing how aerospace amorphous has become a driving force in the continuous development of space exploration.

1.Aerospace amorphous preface overview

(1) Progress of aerospace technology

In recent years, space technology has made great progress, from satellite technology to deep space exploration, human cognition and utilization of the universe is rapidly improving. Every leap in space technology cannot be separated from the support of materials science. The development and application of new materials is one of the important factors in promoting the progress of space technology.

(2) Revolution in materials science

In the field of materials science, a revolution is quietly underway. Amorphous alloy, a new material called “metal glass”, has attracted the attention of scientists and engineers with its unique properties and wide application prospects. The emergence of amorphous alloys not only challenges the traditional concept of materials science, but also provides new possibilities for the development of space technology.

(3) Introduction of Amorphous Alloys

Amorphous alloys, a type of metallic material without a crystalline structure, have many excellent physical and chemical properties due to the long-range disorder of their atomic arrangement. Compared with conventional crystalline alloys, amorphous alloys have higher strength, hardness and toughness, as well as good corrosion resistance and magnetic properties. These properties make amorphous alloys in the field of aerospace applications are promising, from structural materials to functional materials, there are aerospace amorphous figure.

2.Basic concepts and properties of amorphous alloys

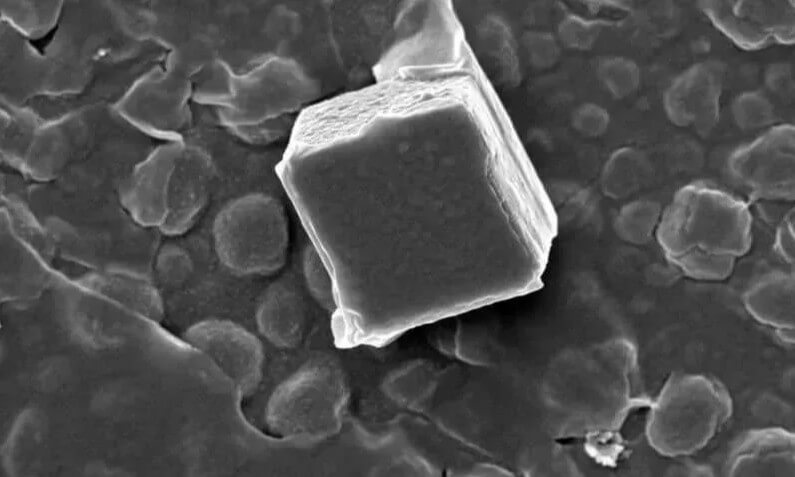

(1) Definition of amorphous alloy

Amorphous alloy, also known as metal glass, is a kind of solid material formed by rapidly cooling the metal liquid so that its atoms are too late to form an orderly crystal structure. The arrangement of atoms in this material exhibits long-range disorder and short-range order, which is significantly different from the regular crystal structure of conventional crystalline alloys. This unique structure gives amorphous alloys many extraordinary properties.

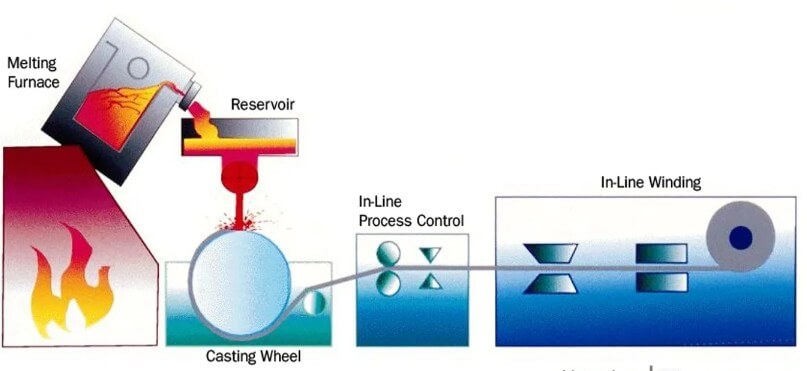

(2) Formation principle of amorphous alloys

The key to the formation of amorphous alloys lies in the cooling rate. Through the extremely fast cooling rate, it is possible to avoid the formation of crystal structure during the solidification process of the metallic liquid. Specifically, as the metallic liquid cools at millions of degrees per second, the atoms are too late to rearrange themselves into a crystal structure, resulting in the formation of an amorphous state. This formation process is similar to the formation of glass, which is why amorphous alloys are also known as metallic glasses.

(3) Classification of Amorphous Alloys

Classification by composition

1) Metal-metal amorphous alloys

Mainly composed of two or more metal elements, such as Zr-Cu-Al-Ni.

These alloys usually have good glass formation ability and excellent mechanical properties.

2) Metal – metal-like amorphous alloys

Composed of transition metals and metal-like elements (such as B, P, C, Si, etc.), such as Fe-Si-B, Co-Fe-Si-B, etc..

These alloys are widely used in magnetic devices due to their high permeability and low loss.

Categorized by structure

1) Single-phase amorphous alloys

The internal structure of the alloy is homogeneous, with no obvious phase separation, showing the characteristics of isotropy.

Typical representatives such as Pd-Cu-Si, Fe-B-Si and so on.

2) Composite amorphous alloy

Composed of amorphous matrix and nanocrystalline or microcrystalline phase, obtained by appropriate heat treatment process.

For example, Fe-Cu-Nb-Si-B (nanocrystalline alloy), combining the advantages of amorphous and crystalline, has higher magnetic properties and mechanical properties.

(4) Properties of amorphous alloys

Amorphous alloys have many unique properties that make them widely applicable in several fields.

First, they have high strength and hardness, which makes amorphous alloys perform well when subjected to heavy loads and impacts. Second, amorphous alloys have good corrosion resistance and can maintain stability in harsh environments. In addition, amorphous alloys also exhibit excellent resistance to radiation, which is especially important in the space environment, as space radiation causes great damage to materials. These properties make aerospace amorphous play an important role in spacecraft manufacturing.

3.Application areas of aerospace amorphous

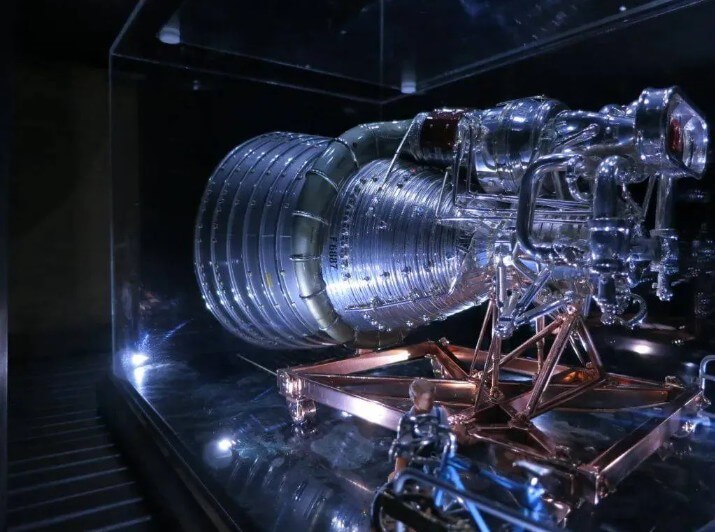

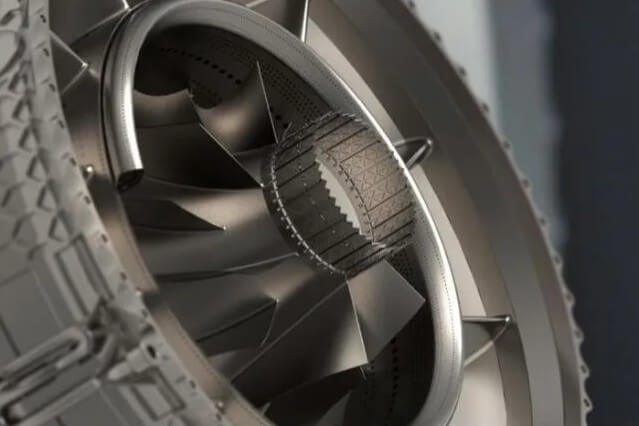

(1) Lightweight and high-strength structural materials

In spacecraft design, reducing structural weight is the key to improving performance. Due to its high strength and high hardness, amorphous alloy can be used as an ideal lightweight structural material for the manufacture of spacecraft frames, panels and other load-bearing parts. The application of aerospace amorphous can not only reduce the overall weight of spacecraft, but also improve their load-bearing capacity and safety.

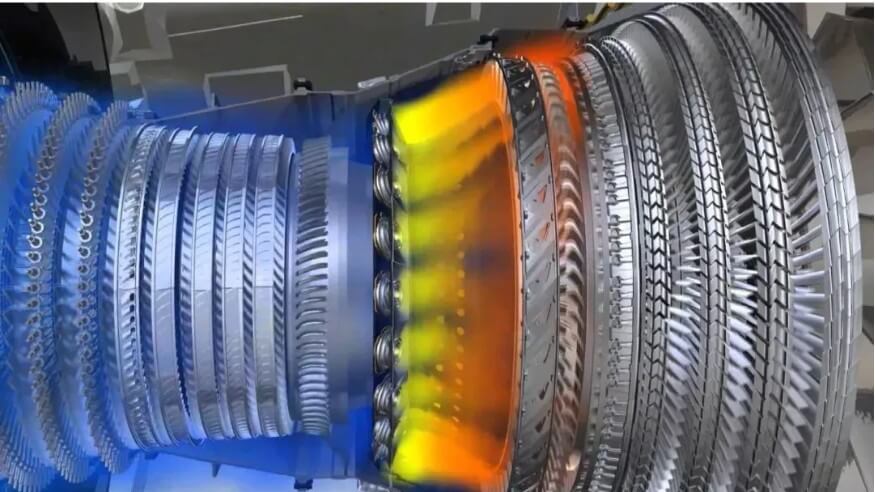

(2) High-efficiency energy conversion and storage materials

Amorphous alloys also show great potential in energy conversion and storage. For example, amorphous alloys can be used to manufacture more efficient solar cells and fuel cells to improve the conversion efficiency of energy. In addition, amorphous alloys can be used to develop new battery technologies that offer higher energy density and longer cycle life.

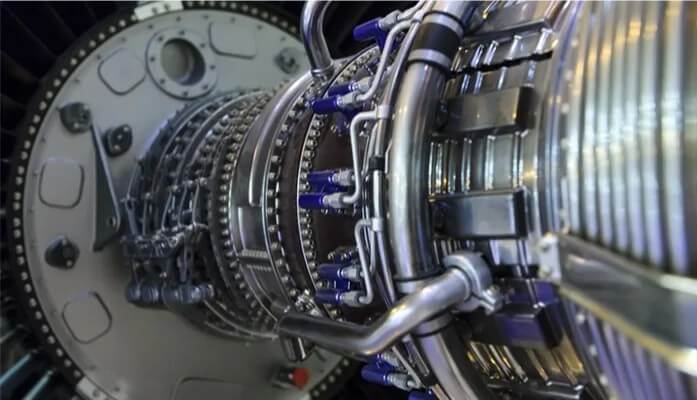

(3) Radiation and heat resistant protective materials

Spacecraft face harsh radiation and temperature change environments in space. Amorphous alloys can be used as effective protective materials to protect spacecraft and astronauts from radiation damage and extreme temperatures due to their excellent radiation resistance and high temperature resistance. The application of aerospace amorphous is of great significance to improve the reliability and safety of spacecraft.

4.Challenges and prospects of aerospace amorphous

(1) Optimization of preparation process

Although amorphous alloys have many excellent properties, their preparation process still faces some challenges. Currently, the preparation of amorphous alloys mainly relies on rapid cooling techniques, which limits the size and shape of the material. In addition, the high temperatures and pressurized conditions during the rapid cooling process place higher demands on equipment and technology. In order to promote the wide application of amorphous alloys, it is necessary to further optimize the preparation process, reduce the cost and improve the production efficiency.

(2) Exploration of performance optimization

In order to meet the extreme demand for material properties in the aerospace field, scientists and technicians are constantly exploring ways to optimize aerospace amorphous properties. By adjusting the alloy composition and preparation parameters, the mechanical properties, thermal stability and radiation resistance of amorphous alloys can be further improved. For example, adding an appropriate amount of rare earth elements can significantly improve the strength and toughness of amorphous alloys, while controlling the cooling rate can optimize the microstructure of the material and improve its comprehensive performance.

(3) Expansion of application fields

With the progress of technology and process improvement, amorphous alloys are constantly expanding the field of application. In addition to aerospace, amorphous alloys in medical devices, electronic equipment, energy storage and other fields also show broad application prospects. For example, amorphous alloys can be used to manufacture high-performance surgical instruments and implants with excellent biocompatibility and wear resistance; in the field of electronic equipment, amorphous alloys can be used to manufacture high-efficiency inductors and transformers to improve the performance and reliability of equipment.

5.Conclusion

The application of amorphous alloys in modern science and technology, especially in the field of aerospace, shows its irreplaceable and critical role. Aerospace amorphous with its unique performance makes the spacecraft better adapted to the extreme environment of space and improves the performance and safety of the vehicle.

What do you think?

[…] at extreme temperatures, these robots are more reliable in extreme environments. For example, space exploration robots can perform complex tasks under extreme temperature and radiation conditions, while deep-sea […]