Investment Casting

BENEFITS

Investment casting casting alloys are not restricted and can be used for high melting point and difficult-to-cut alloys, which shows its significant advantages.

Precision investment cast parts can be cast in a variety of alloys, including stainless steel, brass, bronze, cobalt, nickel and custom alloys.

FEATURES

Metal investment casting begins with a wax pattern, which is recycled, cleaned and reshaped multiple times. Metal investment casting also produces net or near-net shape parts, significantly reducing or eliminating secondary processing scrap. Metal casting is a very green and environmentally friendly process.

BENEFITS

Typically, the “standard” investment tolerance is +/- 0.010” for the first inch and +/- 0.004” for each subsequent inch.

Drawings can be generated during the design phase to reduce or even eliminate previous machining requirements to produce the same part.

FEATURES

The cost of any part increases with the accuracy required to its dimensions. Whether it is a casting, machined component or a fabricated component. A careful design review will allow for modifications to tolerances, undercuts, blind holes, etc. to achieve higher production yields and lower part costs. If a tighter tolerance than the casting tolerance is required, then the investment casting will require less machining than a conventional casting or fabricated component.

BENEFITS

Investment casting provides consistent and repeated close tolerances as well as complex channels and contours. Many of these configurations are impossible to produce. For example, where machine tools cannot reach. Achieving net shape or near net shape cast parts can significantly reduce post-casting machining costs.

FEATURES

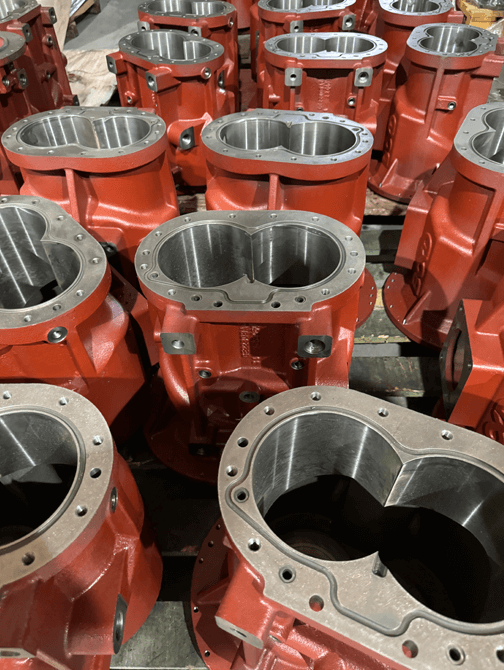

Investment castings are a good alternative to welded or fabricated parts. Many components can be combined into a single casting. The more components that are combined, the more efficient the manufacturing process. Converting a multi-piece assembly to a single investment casting often improves dimensional accuracy and reduces part complexity.

Applications & Grades

Investment castings are typically able to maintain tolerances of +/- 0.005 inches per inch. However, under certain conditions, tolerances of +/- 0.003 can be achieved. Tighter tolerances beyond typical investment casting standards can be achieved through machining processes.

- Crankshaft & Connecting Rod

- Nuclear reactor components

- Burner Nozzles & Hydraulic Components

- Marine Propulsion & Turbomachinery