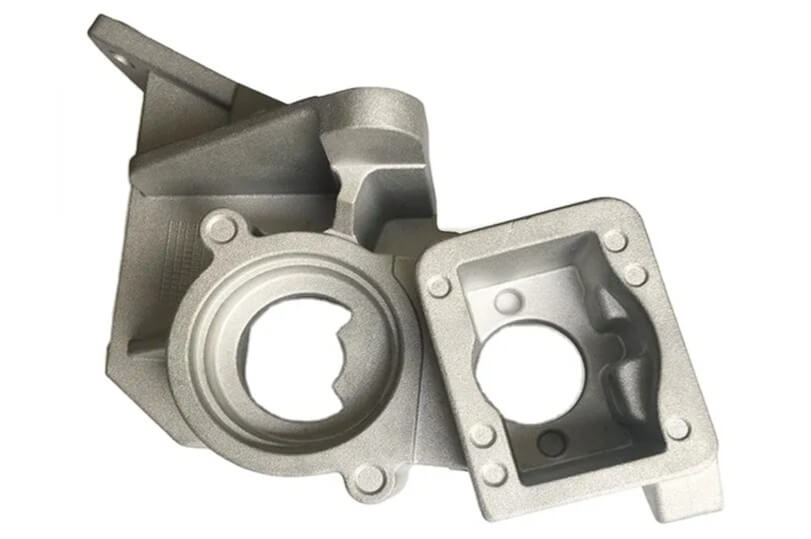

Investment casting vs sand casting: similarities and differences analysis

As two important metal casting processes, investment casting vs sand casting each have unique advantages and scope of application. This article will analyze the similarities and differences between the two casting processes in detail from the aspects of process flow, application characteristics, advantages and disadvantages.

1.Similarities and differences between investment casting vs sand casting process flow

(1) Investment casting process flow

Investment casting, also known as lost wax casting, mainly includes the following steps:

1) Wax mold making:

First, make a wax mold according to the part drawing. The size and shape of the wax mold are consistent with the final casting.

2) Module combination:

Combining multiple wax molds on a wax stick to form a module for subsequent operations.

3) Shell making:

Coating refractory material on the wax mold group to form a ceramic shell, and then drying and hardening it.

4) Dewaxing:

Heating the prepared shell to melt the wax mold and form a cavity.

5) Firing and pouring:

The mold shell is calcined at high temperature to remove residual wax and increase the strength of the mold shell, and then the molten metal is poured.

6) Cooling and post-processing:

After the molten metal cools and solidifies, the mold shell is broken, the casting is taken out, and necessary post-processing such as grinding and heat treatment is performed.

(2) Sand casting process

The process of sand casting is relatively simple and mainly includes the following steps:

1) Mold preparation:

Make a wooden mold or metal mold according to the part drawing.

2) Modeling:

Fill the mold sand into the mold and compact the mold sand by manual or mechanical methods to form a sand mold.

3) Closing:

Close the upper and lower sand boxes to form a complete casting.

4) Pouring:

Pour the molten metal into the casting.

5) Cooling and sand dropping:

After the molten metal cools and solidifies, break the sand mold and take out the casting.

6) Post-processing:

The casting is cleaned, polished, heat treated and other post-processing steps are performed.

(3) Summary of the similarities and differences between investment casting vs sand casting in the process flow

1) Similarities:

Both are one-time castings, and the casting process has many steps, and both require post-processing steps, such as cleaning and polishing.

2) Differences:

The process flow of investment casting is more complicated, including wax model making, shell making, dewaxing and other steps, while the process flow of sand casting is relatively simple, mainly including modeling, box assembly, pouring and other steps.

2.Similarities and differences in the application characteristics of investment casting vs sand casting

(1) Application characteristics of investment casting

1) High precision and surface quality:

Investment castings have high dimensional accuracy and low surface roughness. The general accuracy can reach CT4-6 and the surface roughness can reach Ra25-6.3μm.

2) Suitable for castings with complex shapes:

It can cast castings with complex shapes, such as parts with fine grooves, curved fine holes, etc. that are difficult to manufacture by other methods.

3) Wide range of applications:

There is almost no limit to the types of casting alloys, and it is often used to cast alloy steel parts, carbon steel parts and heat-resistant alloy castings.

4) Flexible production batch:

It can be produced from single pieces to batches, with strong adaptability.

(2) Application characteristics of sand casting

1) Low cost:

The cost of sand casting is relatively low, and there are no special constraints on product structure, complexity, casting material, weight, etc. It is the most widely used casting method.

2) Suitable for large castings:

It can cast large and heavy castings, such as machine tool accessories, mechanical hardware, automobile and motorcycle accessories, etc.

3) Mechanized and automated production:

With the development of casting technology, sand casting can also realize mechanized and automated production mode to improve production efficiency.

(3) Summary of the similarities and differences between investment casting vs sand casting in terms of application characteristics

1) Similarities:

Both can be used for casting various alloys, and both have certain mechanized and automated production capabilities.

2) Differences:

Investment casting is suitable for small and medium-sized castings with high precision and complex shapes, while sand casting is suitable for large and heavy castings, with lower costs and greater versatility.

3.Similarities and differences between the advantages and disadvantages of investment casting vs sand casting

(1) Advantages and disadvantages of investment casting

● Advantages:

1) High precision and surface quality:

The dimensional accuracy and surface quality of the casting are better than other casting methods.

2) Design flexibility:

It can produce parts with complex shapes and reduce the workload of subsequent processing.

3) Wide range of applications:

It can cast various alloys, including high melting point alloys.

● Disadvantages:

1) High cost:

Due to the complex process flow, the material and labor costs are high.

2) Low production efficiency:

The production cycle is long and not suitable for large-scale production.

3) Complex process:

The process is complex, and there are many factors that affect the dimensional accuracy of the casting.

(2) Advantages and disadvantages of sand casting

● Advantages:

1) Low cost:

The cost of materials and equipment is relatively low, suitable for large-scale production.

2) Wide range of applications:

Castings of various shapes and sizes can be cast, including large and heavy castings.

3) Simple process:

The process is relatively simple and easy to operate.

● Disadvantages:

1) Low accuracy and surface quality:

The dimensional accuracy and surface quality of the casting are not as good as those of investment casting.

2) High labor intensity:

Manual operations are more frequent and the labor intensity is high.

3) Environmental pollution:

More dust and waste will be generated during the sand casting process, causing certain pollution to the environment.

(3) Summary of similarities and differences between investment casting vs sand casting in terms of advantages and disadvantages

1) Similarities:

Both have certain advantages and disadvantages, and it is necessary to select the appropriate casting method according to specific production needs.

2) Differences:

The advantages of investment casting are high precision and surface quality, and it is suitable for complex-shaped castings, but the cost is high and the production efficiency is low; the advantages of sand casting are low cost and wide application range, but the precision and surface quality are low and the labor intensity is high.

4.How to choose between investment casting vs sand casting in practical applications?

When choosing between investment casting vs sand casting, the following factors need to be considered:

(1) Casting precision and surface quality requirements:

If the casting requires high precision and surface quality, such as aerospace, medical equipment and other fields, investment casting should be selected; if the precision and surface quality requirements are not high, such as general mechanical parts, sand casting can be selected.

(2) Casting shape and size:

For castings with complex shapes and small sizes, investment casting is a better choice; for large and heavy castings, sand casting has more advantages.

(3) Production batch:

If it is a small batch or single piece production, investment casting can meet the needs; if it is a large-scale production, the cost advantage of sand casting is more obvious.

(4) Materials and costs:

Investment casting is suitable for various alloys, but the cost is relatively high; sand casting is cheaper, but the choice of materials and equipment is relatively limited.

(5) Environmental requirements:

The sand casting process will produce a lot of dust and waste, which will cause great pollution to the environment, while investment casting has relatively good environmental performance.

5.Summary

In summary, investment casting vs sand casting each have their own advantages and scope of application. In practical applications, it is necessary to comprehensively consider factors such as the precision, shape, size, production batch, material and cost of the casting and select the appropriate casting process to achieve the best production effect and economic benefits.