Exploring the fractal strength of steel under heat

High temperature environment poses a severe challenge to the performance of steel, especially the fractal strength of steel under heat. In recent years, the application of fractal theory in materials science has gradually deepened, providing a new perspective for studying the strength of steel in hot state.

This paper aims to explore the fractal strength characteristics of steel in hot state, in order to provide a theoretical basis for the optimization of heat treatment process of steel.

1.Fractal strength theory

Fractal strength theory is a theory used to describe the fracture and damage behavior of materials under complex stress states. The theory believes that the fracture surface of the material has self-similarity, and the degree of this self-similarity can be quantified by the fractal dimension. In materials science, fractal strength theory is widely used to analyze the fracture toughness of metals, ceramics and composite materials.

Among them, the exploration of the fractal strength of steel in hot state not only helps to optimize the heat treatment process of materials, but also expands its application range and improves the efficiency and product quality of industrial production.

2.Fractal strength of steel under heat – microstructure evolution

During the heating process, the microstructure of steel will undergo significant changes, mainly manifested in the formation and growth of austenite, grain refinement and carbide dissolution. These microstructural changes directly affect the mechanical properties of steel.

(1) Formation and growth of austenite:

When steel is heated above Ac1 temperature, pearlite will transform into austenite. As the heating temperature increases and the holding time increases, the austenite grains will gradually grow. The size of austenite grains has an important influence on the mechanical properties of steel. The finer the grains, the higher the strength and the better the plasticity of the steel.

(2) Grain refinement:

During the hot working process, steel will undergo dynamic recrystallization and static recrystallization, which help to refine the grains. Refined grains can increase the strength of steel while improving its plasticity and toughness.

(3) Carbide dissolution:

The carbides in the steel will gradually dissolve into the austenite during the heating process. The degree of carbide dissolution affects the hardness and strength of steel. Appropriate carbide dissolution can improve the strength of steel, but excessive dissolution will cause the hardness of steel to decrease.

3.Fractal strength of steel under heat – Application of fractal theory in steel strength research

The application of fractal theory in steel strength research mainly focuses on the following aspects:

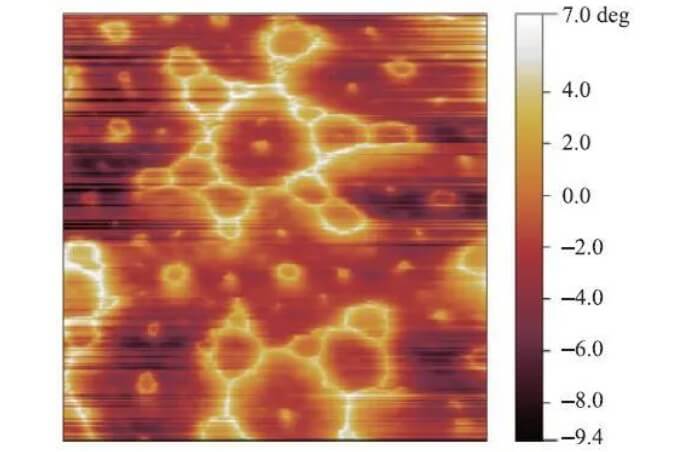

(1) Fractal analysis of microstructure morphology:

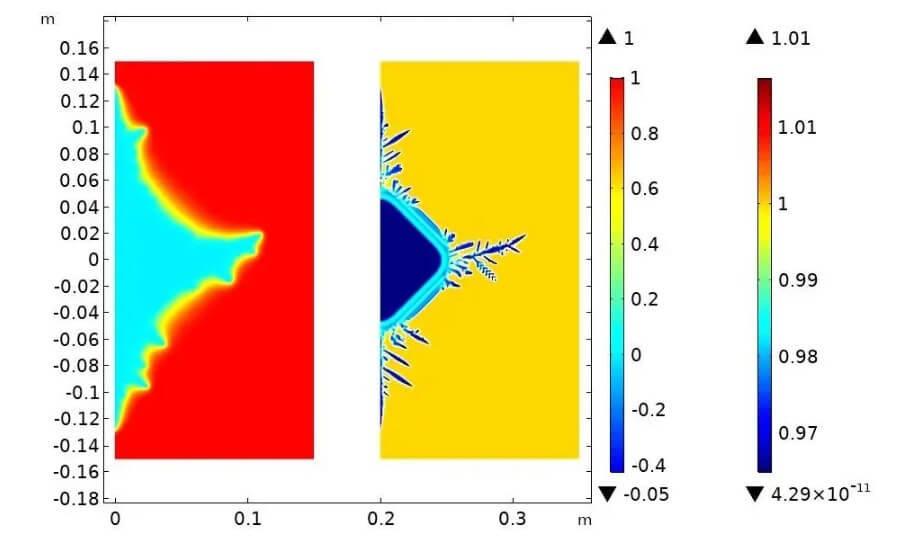

The microstructure of steel, such as grains, carbides, etc., has fractal characteristics. By calculating the fractal dimension, the complexity of these microstructures can be quantitatively described. The higher the fractal dimension, the higher the complexity of the microstructure and the higher the strength of the steel.

(2) Fractal analysis of stress-strain curve:

In hot state, the stress-strain curve of steel also shows fractal characteristics. By fractal analysis of stress-strain curve, the deformation mechanism of steel in hot state and its relationship with strength can be revealed.

(3) Fractal analysis of fracture surface:

The fracture surface of steel has a complex fractal structure, and the fractal dimension can reflect the roughness of the fracture surface. There is a certain relationship between the fractal dimension of the fracture surface and the strength of the steel. High-strength steel usually has a fracture surface with a higher fractal dimension.

4.Factors affecting the fractal strength of steel under heat

(1) Heating temperature:

Heating temperature is an important factor affecting the fractal strength of steel under heat. As the heating temperature increases, the austenite grains will gradually grow, and the fractal dimension of the microstructure will decrease, resulting in a decrease in the strength of the steel. However, appropriate heating temperature can promote carbide dissolution and grain refinement, thereby improving the strength of the steel.

(2) Holding time:

The holding time also has an important influence on the microstructure of the steel. Too long holding time will cause excessive growth of austenite grains, reducing the strength of the steel. Appropriate holding time helps to refine the grains and uniform the structure, thereby improving the strength of the steel.

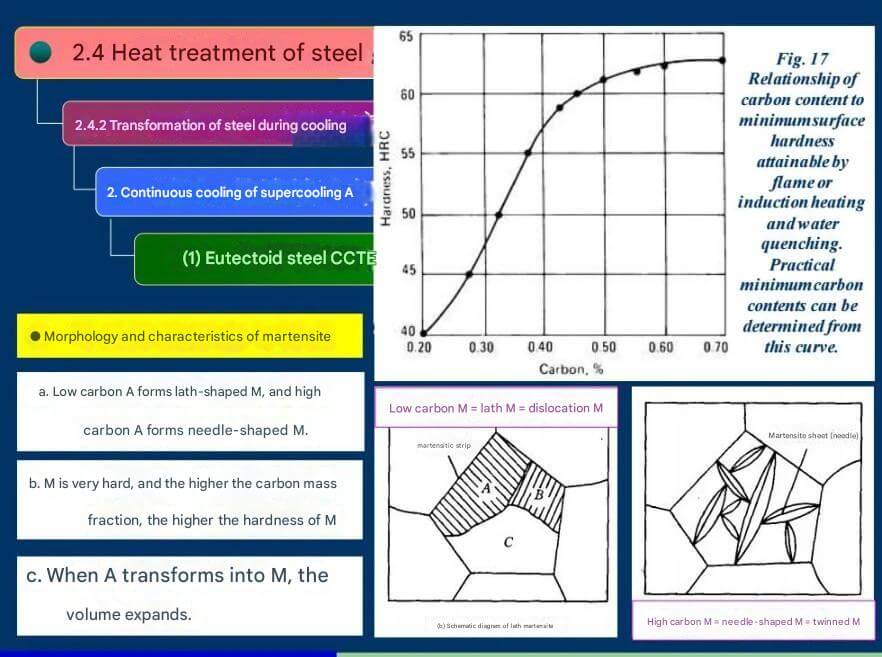

(3) Cooling rate:

Cooling rate is another key factor affecting the fractal strength of steel under heat. Different cooling rates will lead to different microstructures, thus affecting the strength of the steel. For example, rapid cooling can promote the formation of martensite and increase the hardness of steel, but it will also reduce its plasticity.

(4) Chemical composition:

Chemical composition also has an important influence on the fractal strength of steel under heat. Elements such as carbon, manganese, and silicon can increase the strength of steel, while impurity elements such as sulfur and phosphorus can reduce the strength and plasticity of steel. By rationally controlling the chemical composition, the microstructure of steel can be optimized and its fractal strength in a hot state can be improved.

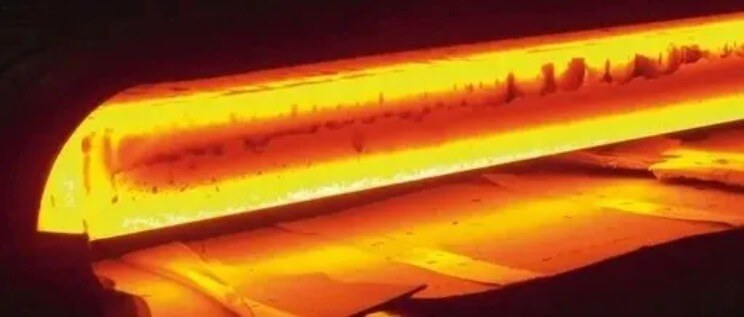

(5) Hot working process:

Hot working processes, such as casting and rolling, can change the microstructure of steel, thereby affecting the fractal strength of steel under heat. Appropriate hot working processes can promote dynamic recrystallization and static recrystallization, refine grains, and improve the strength and plasticity of steel.

5.At what temperature will structural steel lose strength?

Structural steel will gradually lose its original strength when the temperature rises to a certain range. The following are specific explanations:

(1) Within 200℃:

The performance of structural steel does not change significantly within this temperature range, and its heat resistance is good.

(2) Around 250℃:

Although the tensile strength of steel may increase slightly, the plasticity and toughness begin to decrease, and the material tends to become brittle. This phenomenon is called blue brittleness.

(3) After 300℃:

The strength gradually decreases, and the plastic deformation capacity increases.

(4) 450-650℃:

In this temperature range, the strength of steel is almost completely lost, and the structure loses its bearing capacity. Therefore, the applicable temperature of steel structure is usually not higher than 250℃.

(5) At 500℃:

The yield strength of steel is about 2/3 of the optimal yield strength.

(6) At 600℃:

The yield strength of steel is only 1/3 of the optimal yield strength. At this time, the steel almost completely loses its strength and is prone to buckling and plastic deformation, causing the steel structure to lose stability.

In summary, the strength of structural steel begins to decrease significantly after the temperature exceeds 300℃, and it almost completely loses its strength at 600℃. Therefore, when designing and applying steel structures, the influence of ambient temperature must be considered to ensure the safety and reliability of the structure. If the ambient temperature may exceed the tolerance range of the structural steel, appropriate fire prevention and heat insulation measures should be taken.

6.Conclusion

In summary, the fractal strength evolution mechanism of steel in a hot state is mainly related to the evolution of its microstructure. With the increase of temperature, the grain size of steel grows and the dislocation density decreases, resulting in a decrease in its strength, while the change in fractal dimension reflects the complexity of this process. Further analysis can focus on the influence of different alloying elements on the fractal strength of steel under heat, providing guidance for the development of high-temperature steel.