Does stainless steel tarnish? How to prevent and repair it

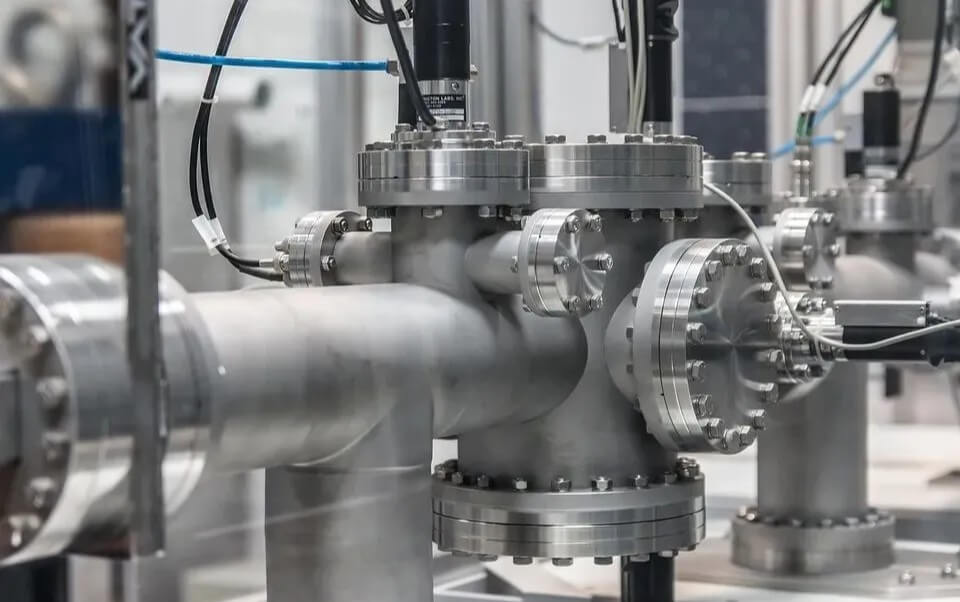

Stainless steel has been widely used in modern society for its superior corrosion resistance and unique luster. From kitchen utensils to architectural decoration, from medical equipment to industrial equipment, stainless steel plays an important role.

However, does stainless steel tarnish? Many people have this question. It is not difficult to find that after a period of use or exposure to certain environments, the luster of stainless steel seems to gradually disappear, and even rust spots appear. Why is this? This article will discuss in detail the reasons, prevention and treatment measures for stainless steel losing its luster, as well as the scientific principles behind it.

1.Does stainless steel tarnish? Analysis of the reasons for losing luster

(1) Damage to the surface oxide film

The reason why stainless steel has excellent corrosion resistance is mainly due to the dense oxide film formed on its surface. This oxide film is mainly composed of chromium and oxygen, usually called a passivation film. This film is very thin, but it can effectively prevent oxygen and corrosive substances from further eroding the stainless steel matrix. However, when this oxide film is mechanically damaged or chemically corroded, does stainless steel tarnish? The answer is yes.

1) Mechanical damage:

During daily use, the surface of stainless steel may be damaged by friction, scratches, etc., causing the oxide film to be damaged. For example, when using a steel wool or hard cleaning tool to wipe the surface of stainless steel, this protective film may be damaged. Once the oxide film is damaged, the stainless steel will be exposed to the air, gradually oxidize and lose its luster.

2) Chemical corrosion:

Certain chemicals such as inorganic acids such as chlorides, sulfuric acid, and nitric acid, as well as organic acids such as acetic acid and formic acid, will damage the oxide film on the surface of stainless steel. Chlorides, in particular, are extremely common in nature and daily life, such as salt, sauces, disinfectants, etc. If stainless steel is exposed to these substances for a long time and is not cleaned in time, the surface oxide film will gradually be damaged, causing it to lose its luster.

(2) Environmental factors

Does stainless steel tarnish? When stainless steel is in a marine environment and an industrial environment for a long time, it will gradually corrode and lose its luster.

1) Marine environment:

The high salt and high humidity in the marine environment are extremely corrosive to stainless steel. Long-term exposure to the marine environment will cause brown rust and spots on the surface of stainless steel. This is because chloride ions will destroy the passivation film on the surface of stainless steel, causing the base metal to be exposed to the corrosive medium and gradually oxidize and rust.

2) Industrial environment:

There are a large number of corrosive gases and particulate matter in the industrial environment, such as sulfur dioxide, nitrogen oxides, dust, etc. These substances will adhere to the surface of stainless steel, forming an electrolyte solution, accelerating the corrosion process, and causing the stainless steel to lose its luster.

(3) Differences in material composition and grades

Does stainless steel tarnish? Yes. The reason for its loss of luster is also closely related to the material. Different grades of stainless steel have significant differences in corrosion resistance due to their different compositions. Common stainless steel grades include 200 series, 300 series, 400 series, etc. Among them, the 300 series (such as 304, 316) has better corrosion resistance because it contains higher chromium and nickel, while the 200 series and 400 series have relatively poor corrosion resistance.

1) Influence of chemical composition:

In addition to chromium and nickel, stainless steel also contains carbon, phosphorus, sulfur, molybdenum, titanium, copper, niobium and other elements. The content of these elements will also affect the corrosion resistance of stainless steel. For example, molybdenum can improve the corrosion resistance of stainless steel in chloride environment, while sulfur and phosphorus may reduce its corrosion resistance.

2) Influence of organizational structure:

The organizational structure of stainless steel will also affect its corrosion resistance. According to the different organizational structures, stainless steel can be divided into several categories such as austenite, ferrite, martensite and duplex stainless steel. Among them, austenitic stainless steel (such as 304) is the most widely used because of its good toughness and corrosion resistance.

2.Common corrosion types of stainless steel

Does stainless steel tarnish? According to the above, we know that a big reason why stainless steel loses its luster is that the stainless steel material is corroded, which will cause it to lose its luster. The following will introduce four common corrosion types of stainless steel.

(1) Intergranular corrosion:

This is a form of corrosion along the edge of metal grains. Although intergranular corrosion does not cause significant changes in the metal’s appearance, it can dramatically reduce the mechanical properties of structures and parts, and may cause sudden equipment failure.

(2) Pitting:

Also known as pitting corrosion, it is characterized by corrosion concentrated in a small area on the metal surface and rapidly developing deep into the metal, which may eventually lead to metal penetration. Pitting is mainly caused by defects on the metal surface that lead to the destruction of the passivation layer.

(3) Crevice corrosion:

Occurs in the medium. When a tiny gap is formed between metal and metal or metal and non-metal, the medium in the gap is accelerated to corrode due to the stagnant state.

(4) Stress corrosion cracking:

It is a form of damage caused by the combined action of static tensile stress and corrosion, manifested as brittle fracture. The causes are static tensile stress, environment, and sometimes metallurgical conditions.

3.Does stainless steel tarnish? Methods to prevent tarnishing

Does stainless steel tarnish? How to prevent stainless steel from losing its luster? We should consider this issue from the following points.

(1) Proper cleaning and maintenance

1) Daily cleaning:

In daily use, avoid using steel wool, hard cleaning tools, etc. to cause mechanical damage to the stainless steel surface. You can use soft cloth, sponge, etc. with neutral detergent for cleaning. After cleaning, rinse with clean water in time and wipe dry to prevent moisture from remaining and causing corrosion.

2) Regular maintenance:

Regularly maintain stainless steel. You can use special stainless steel maintenance oil or wax, apply it on the stainless steel surface to form a protective film to prevent oxidation and corrosion.

(2) Environmental control

1) Avoid harsh environments:

Try to avoid exposing stainless steel to harsh environments, such as marine environments, industrial environments, etc. If stainless steel must be used in these environments, choose a grade with better corrosion resistance and take corresponding protective measures.

2) Ventilation and drying:

Maintaining the use environment ventilated and dry can effectively reduce the accumulation of corrosive gases and residual moisture, and reduce the risk of corrosion of stainless steel.

(3) Select the appropriate material

1) Select the grade according to the use environment:

When selecting stainless steel materials, the appropriate grade should be selected according to the requirements of the use environment. For example, in marine environments, grades with good chloride corrosion resistance should be selected, such as 904L, 2205, 316L, etc.; in industrial environments, austenitic stainless steel with good corrosion resistance should be selected, such as 304, 316, etc.

2) Control chemical composition:

In the production process of stainless steel, the chemical composition should be strictly controlled to ensure that the content of chromium and nickel meets the requirements, while minimizing the content of harmful elements such as sulfur and phosphorus to improve the corrosion resistance of stainless steel.

4.Comparison of corrosion resistance of different grades of stainless steel

(1) Austenitic stainless steel

Austenitic stainless steel is the most common type of stainless steel, with good corrosion resistance, toughness and processing performance. Common austenitic stainless steel grades include 304, 316, etc.

Among them, 304 stainless steel contains 18% chromium and 8% nickel, and is widely used in food processing, kitchen utensils, medical equipment and other fields; 316 stainless steel increases the content of molybdenum on the basis of 304, improves the corrosion resistance in chloride environment, and is suitable for marine environment, chemical equipment and other fields.

(2) Ferritic stainless steel

Ferritic stainless steel is mainly composed of iron and chromium, and has relatively poor corrosion resistance, but has good thermal conductivity and magnetism. Common ferritic stainless steel grades include 430, etc. It is mainly used in home appliances, building decoration and other fields.

(3) Martensitic stainless steel

Martensitic stainless steel is mainly composed of iron, chromium and carbon, with high strength and hardness, but poor corrosion resistance. Common martensitic stainless steel grades include 410, 420, etc. It is mainly used in knives, bearings and other fields.

(4) Duplex stainless steel

Duplex stainless steel has the advantages of both austenitic and ferritic stainless steels, and has good corrosion resistance, strength and toughness. Common duplex stainless steel grades include 2205, 2507, etc. Mainly used in petrochemical, offshore platforms and other fields.

5.Does stainless steel tarnish? What are the treatment methods after losing its luster?

Does stainless steel tarnish? When stainless steel has lost its luster, what methods can be used to restore its luster? We should consider this issue from the following aspects.

(1) Chemical pickling method

1) Three-acid pickling method:

Use a mixture of sulfuric acid, nitric acid and hydrochloric acid for pickling, which is a more effective method for removing oxide scale.

2) Nitric acid + hydrofluoric acid pickling method:

This method is also one of the better choices for removing stainless steel oxide scale, but hydrofluoric acid is harmful to the environment and human body, so it should be used with caution.

3) Alkali boiling-pickling composite method:

First, loosen the oxide scale by alkaline boiling, and then pickle. This method improves the pickling quality and consumes less metal.

(2) Mechanical treatment method

1) Shot peening/sand blasting:

Remove the oxide scale and rust on the surface by high-speed jetting of abrasives. Shot peening can improve surface roughness and wear resistance, while sand blasting is more flexible but slower.

2) Surface brushing

If you want the stainless steel surface to have a special texture effect, you can use brushing equipment for brushing. After treatment, you can apply a layer of protective oil to increase the wear resistance and glossiness of the surface.

(3) Polishing method

1) Mechanical polishing:

Use polishing cloth or polishing paste for polishing. First coarse grinding and then fine grinding. For coarse grinding, you can use 600# abrasive belt to remove solder joints and deep scratches. For semi-fine grinding, use 800# abrasive belt to correct seams and marks. For fine grinding, use 1000# abrasive belt for further fine grinding to make the surface smooth.

In the light-emitting stage, use a high-speed motor to drive the wool wheel, and use Daqing wax to perform mirror polishing. Finally, use a clean cotton cloth wheel to polish the surface to achieve a mirror effect.

2) Electrolytic polishing

Electrolytic polishing is a more advanced process that can produce extremely high polishing effects. In this process, the stainless steel workpiece is placed in a container containing an electrolyte, and the heat generated by the current dissolves the oxides and other stains on the surface. The electrolytic polishing process is stable and efficient, and is suitable for complex and demanding workpieces.

6.Summary

Does stainless steel tarnish? Although stainless steel has excellent corrosion resistance, it may still lose its luster or even rust when it is improperly used and maintained or exposed to harsh environments. Understand the causes, prevention and treatment measures of stainless steel tarnishing and the scientific principles behind it. It can effectively extend the service life of stainless steel and maintain its beauty and functionality.

What do you think?

[…] how to remove rust from stainless steel? Knowing the correct way to remove rust can not only restore the beauty of the item, but also effectively extend its service life. This article will give you a detailed introduction […]

[…] 3.Stainless steel color […]

[…] (2) Surface treatment […]

[…] Hot working processes, such as casting and rolling, can change the microstructure of steel, thereby affecting the fractal strength of steel under heat. Appropriate hot working processes can promote dynamic recrystallization and static recrystallization, refine grains, and improve the strength and plasticity of steel. […]