Thermally Strengthen Metals: An In-depth Analysis of Solid Solution Strengthening, Age Strengthening, and Other Methods

In modern industry, the performance requirements of metal materials are increasingly stringent, especially in extreme environments such as high temperature, high pressure, and high load, which place higher requirements on the strength, hardness, heat resistance, and corrosion resistance of metal materials.

ITo meet these needs, a variety of thermally strengthen metal techniques have been developed, including solid solution strengthening, aging strengthening and other methods. This paper will analyze these methods of thermally strengthen metal in depth, discussing their principles, applications and advantages.

1.The importance of metal strengthening

In modern industrial and technological applications, the performance of metal materials directly affects the quality and reliability of products. Thermally strengthen metal technology significantly improves its mechanical properties, such as strength, hardness and toughness, by changing the microstructure of metal, thereby meeting the stringent requirements for material performance in different fields. From high-strength alloys in aerospace to lightweight materials in the automotive industry to high-durability steels in building structures, metal strengthening technologies play a vital role.

2.Thermally strengthen metal: solid solution strengthening

(1) Definition and principle

Solid solution strengthening is a thermally strengthen metal method that increases the strength of the metal by adding one or more solute atoms to the metal solvent to form a solid solution.

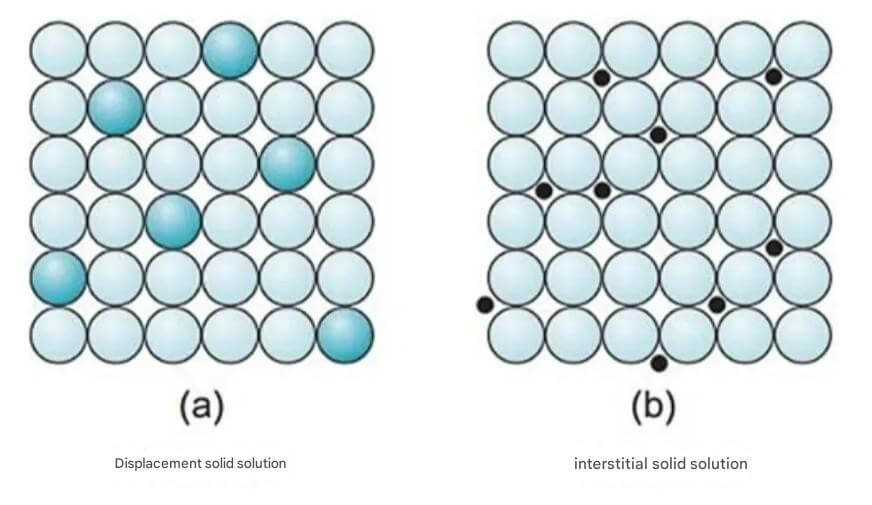

This strengthening mechanism mainly relies on lattice distortion caused by solute atoms, which hinders the movement of dislocations and thereby increases the strength of the metal. According to the position of solute atoms in the solvent lattice, solid solution strengthening can be divided into two types: interstitial solid solution strengthening and substitutional solid solution strengthening.

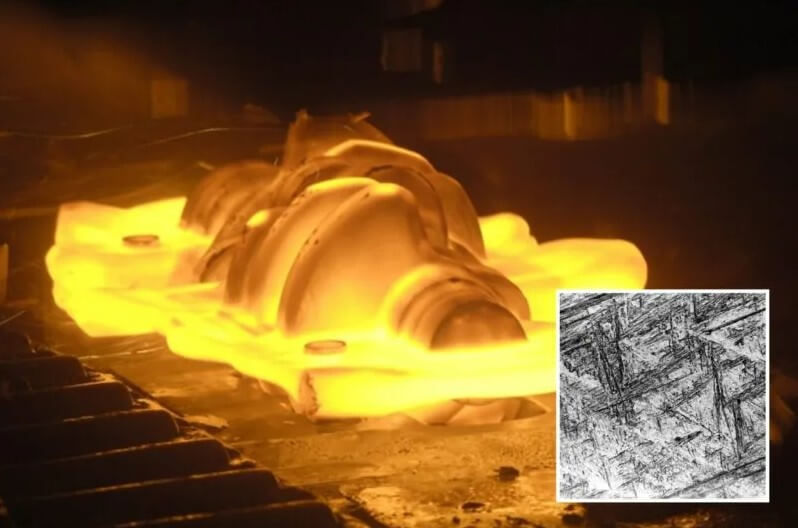

Solid solution strengthening process

(2) Types of solid solution strengthening

1) Replacement solid solution strengthening:

Solute atoms replace some atoms in the solvent lattice, which causes lattice distortion due to the difference in atomic size, thereby enhancing the strength of the metal. This strengthening method is very effective in many alloy systems, such as copper-nickel alloys, aluminum-copper alloys, etc.

2) Interstitial solid solution strengthening:

Solute atoms fill the gaps in the solvent crystal lattice. This method is usually used for the solid solution of smaller solute atoms, such as carbon and nitrogen atoms in the iron matrix. Interstitial solid solution strengthening generally provides greater strength gains than substitutional solid solution strengthening, but may have an adverse effect on the plasticity of the material.

(3) Influencing factors

1) Solute atomic concentration:

The higher the atomic fraction of solute atoms, the greater the strengthening effect. Especially when the atomic fraction is very low, the strengthening effect is more significant.

2) Difference in atomic size:

The greater the atomic size difference between the solute atoms and the matrix metal, the greater the strengthening effect. Interstitial solute atoms have a greater solid solution strengthening effect than replacement atoms.

3) Number of valence electrons:

The greater the difference in the number of valence electrons between the solute atoms and the matrix metal, the more obvious the solid solution strengthening effect, that is, the yield strength of the solid solution increases with the increase in valence electron concentration.

(4) Effect

1) Strength and hardness:

The yield strength, tensile strength and hardness are all stronger than pure metals.

2) Extensibility:

In most cases, the ductility is lower than that of pure metals.

3) Conductivity:

The electrical conductivity is much lower than that of pure metals.

4) Creep resistance:

Strength loss at high temperatures can be improved by solid solution strengthening.

3.Thermally strengthen metal: aging strengthening

(1) Definition and principle

Age strengthening is a method of enhancing the properties of metallic materials through heat treatment, especially for age-hardenable alloys. This thermally strengthen metal method typically involves heating the alloy to a temperature, holding it there for a period of time, and then rapidly cooling it (quenching) to form a supersaturated solid solution.

During the subsequent aging process, supersaturated solute atoms will gradually precipitate to form fine precipitates, which can effectively hinder the movement of dislocations, thereby significantly enhancing the strength of the material.

(2) The process of aging strengthening

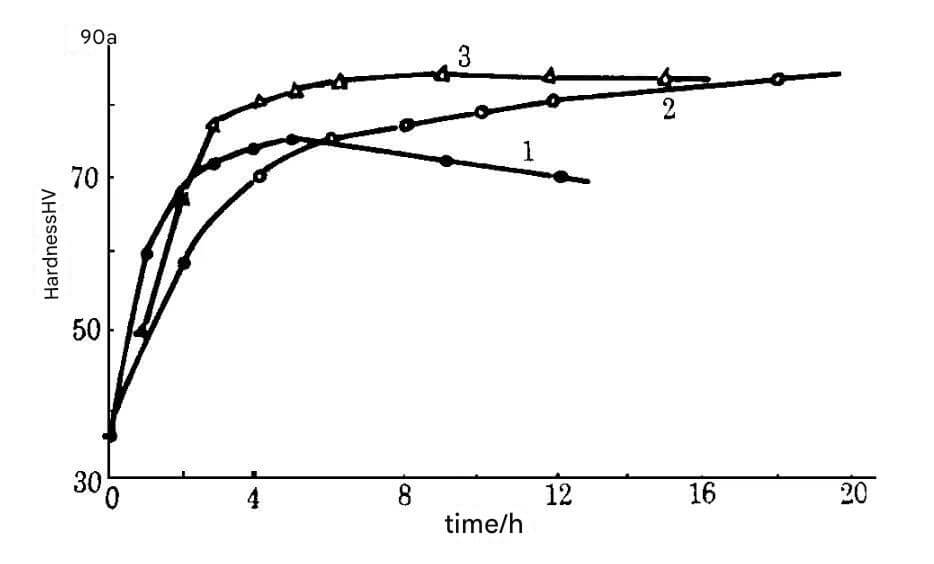

The process of aging strengthening can be divided into two types: natural aging and artificial aging. Natural aging is to store the quenched alloy at room temperature to slowly precipitate solute atoms;

Artificial aging is to heat the alloy to a specific temperature to accelerate the precipitation process of solute atoms. Artificial aging can adjust heating temperature and holding time as needed to optimize material performance.

The change process of aging strengthening of 6063 aluminum alloy

(3) Advantages and Disadvantages of Time Strengthening

1) Advantages:

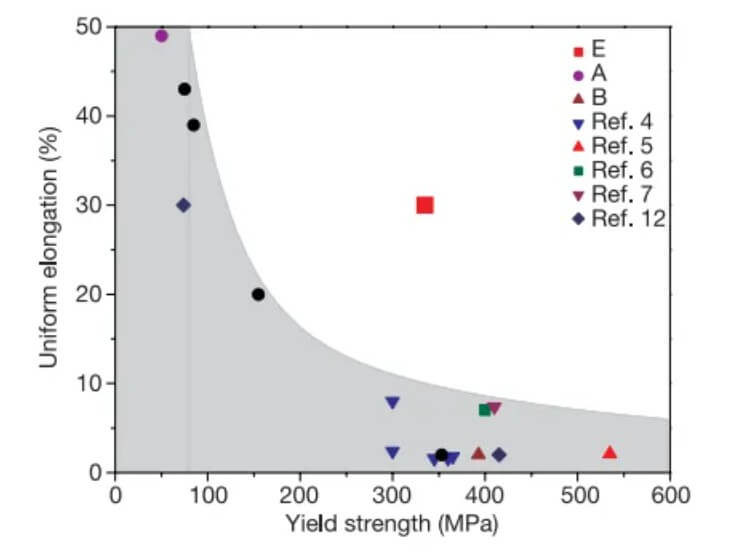

Age strengthening can significantly improve the strength and hardness of materials while maintaining good plasticity and toughness. This method is widely used in the aerospace and automotive industries, as these fields require materials with high specific strength and good fatigue resistance.

2) Disadvantages:

Aging can take a long time, and improper handling can result in material performance degradation. In addition, age strengthening may adversely affect the welding properties of the material.

(4) Application scenarios

Age strengthening is widely used in the production of high-performance alloys, especially in the aerospace sector. For example, aluminum alloys and titanium alloys can be significantly improved in strength through aging treatment and are used to manufacture aircraft structures and engine components. In the automotive industry, age strengthening is also used to manufacture high-strength automotive parts to improve vehicle safety and performance.

4.Other strengthening methods

(1) Fine grain strengthening

Usually metals are polycrystals composed of many grains. The size of the grains can be expressed by the number of grains per unit volume. The greater the number, the finer the grains. Fine-grained metals have higher strength, hardness, plasticity and toughness than coarse-grained metals.

This is because the plastic deformation of fine grains when subjected to external force can be dispersed in more grains. The plastic deformation is more uniform and the stress concentration is smaller. In addition, the finer the grains, the larger the grain boundary area and the more tortuous the grain boundaries. The less conducive to the propagation of cracks.

The refinement of metal grains can improve the room temperature strength of the material and improve the plasticity

(2) Precipitation strengthening

Precipitation strengthening, also known as precipitation strengthening, is a method of increasing the strength of materials by forming fine precipitation phases in the metal matrix. These precipitated phases are usually precipitated from supersaturated solid solutions through aging treatment and can effectively hinder the movement of dislocations.

The effect of precipitation strengthening depends on the nature, quantity, size and distribution of the precipitation phase. By optimizing the process parameters of the aging treatment, the precipitation behavior of the precipitated phase can be controlled to obtain the best strengthening effect.

5.Application fields of thermally strengthen metals

(1) Aerospace

In the aerospace industry, thermally strengthen metals are widely used due to their excellent strength, toughness and fatigue resistance.

For example, titanium alloys and nickel-based superalloys are used to manufacture engine components and aircraft structures through solid solution strengthening and age strengthening to maintain their performance at extreme temperatures. These materials not only need to have high strength and hardness, but also need to have good high temperature resistance and corrosion resistance to ensure the safety and reliability of the aircraft.

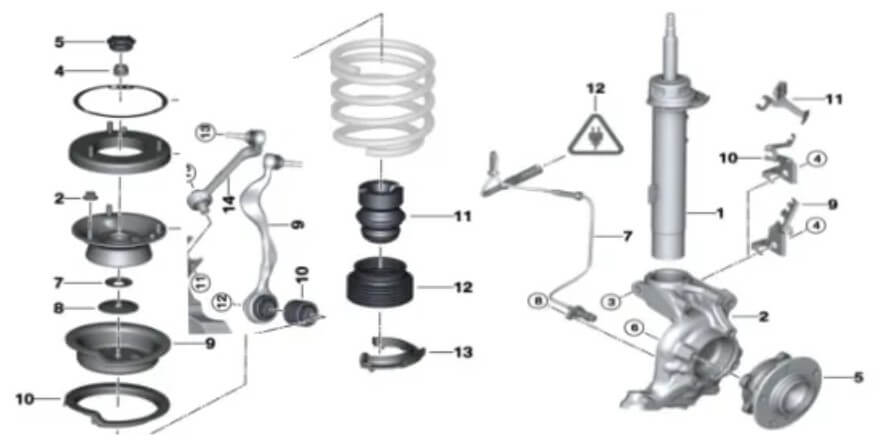

(2) Automobile industry

In the automotive industry, thermally strengthen metals are used to manufacture safety- and performance-critical components such as suspension systems, brake discs, and engine components. Through age strengthening and fine grain strengthening, materials such as aluminum alloys and magnesium alloys can achieve lightweight and high strength, improve fuel efficiency and enhance vehicle safety.

For example, the age-strengthened aluminum alloy suspension system is not only lightweight, but also has high strength and good fatigue resistance, which can improve the vehicle’s handling and comfort.

(3) Architecture and civil engineering

In the construction and civil engineering fields, thermally strengthen metals such as high-strength steel are used in the construction of bridges, high-rise buildings and other structures. Through age strengthening and precipitation strengthening, these materials have higher strength and better durability, and can withstand the test of extreme weather and natural disasters such as earthquakes.

For example, precipitation-strengthened high-strength steel is used to manufacture the main beams and support structures of bridges, which not only improves the load-bearing capacity of the bridge, but also extends its service life.

6.Summary

To sum up, solid solution strengthening, age strengthening and other thermally strengthen metal methods are important means to improve the properties of metal materials. Through in-depth exploration and application of these methods, metal materials with better performance can be developed, providing important material support for the development of modern industry.