Annealed Glass vs. Tempered Glass: A Comprehensive Comparative Analysis

Glass has become one of the indispensable materials in modern construction and manufacturing.

There are many types of glass, among which annealed vs tempered glass are the two most common types. Although the two are similar in appearance, there are significant differences in performance, application and processing methods.

This article will make a detailed comparison between annealed vs tempered glass in terms of definition and production process, mechanical properties, thermal stability, safety, application scenarios, cost and maintenance.

1.Annealed vs tempered glass——definition and production process comparison

(1) Annealed glass:

1) Definition:

Annealed glass refers to a glass product made from ordinary flat glass that is heated to close to the softening temperature (about 600°C) in a heating furnace and then slowly cooled.

2) Production process:

It mainly includes raw material preparation, glass melting, glass forming, and annealing treatment. Annealing treatment is a key link. By controlling the cooling rate, the stress inside the glass is eliminated, the glass structure is made uniform, and its stability and mechanical properties are improved.

(2) Tempered glass:

1) Definition:

Tempered glass is a kind of safety glass that strengthens ordinary glass through physical or chemical methods to significantly improve its mechanical strength and thermal shock resistance.

2) Production process:

It mainly includes cutting, edging, cleaning, tempering and other steps. Tempering treatment usually heats the glass to close to the softening temperature (about 700°C) and then cools it rapidly (usually using air cooling) to form compressive stress on the surface of the glass and tensile stress inside, thereby improving the strength and safety of the glass.

2.Annealed vs tempered glass——comparison of mechanical properties

(1) Strength:

1) Annealed glass:

The mechanical strength is relatively low, and the impact resistance and bending resistance are poor.

2) Tempered glass:

After tempering treatment, its mechanical strength is significantly improved, usually 3-5 times that of annealed glass. Tempered glass can withstand greater impact and bending stress and is not easily broken.

(2) Hardness:

1) Annealed glass:

It has low hardness and is easily scratched.

2) Tempered glass:

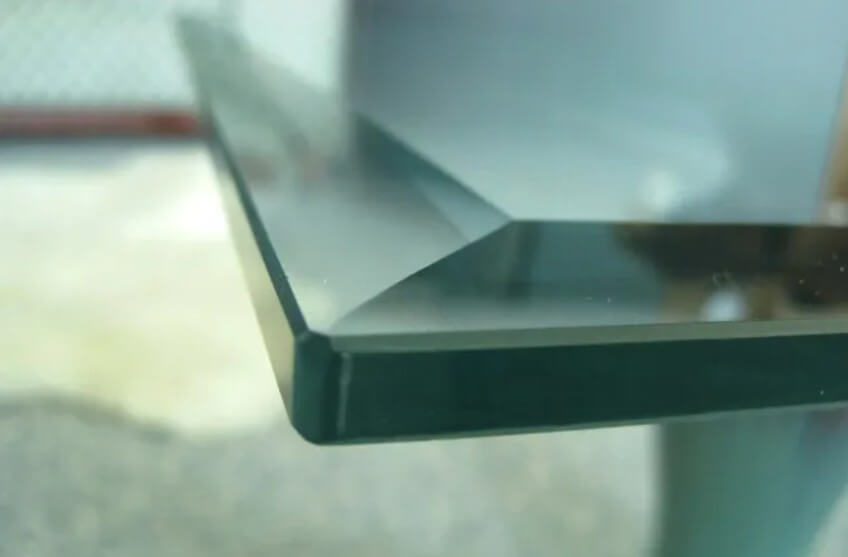

Due to the compressive stress formed on the surface, the hardness is relatively high and the wear resistance is better.

(3) Thermal stability

1) Annealed glass:

It has poor thermal stability and is prone to rupture when the temperature changes greatly. This is because there is a large temperature gradient inside the annealed glass, causing stress concentration.

The temperature range that annealed glass can withstand is relatively small, generally around 70°C.

2) Tempered glass:

It has excellent thermal stability and can withstand large temperature changes without cracking. The temperature range that tempered glass can withstand is generally above 200°C or even higher.

This is because during the heating and cooling process of tempered glass, evenly distributed stress is formed inside, which improves the thermal stability of the glass.

3.Annealed vs tempered glass——safety comparison

(1) Crushing characteristics:

1) Annealed glass:

When broken, sharp fragments will be produced, which can easily cause harm to the human body.

2) Tempered glass:

When broken, fine particles will be formed. These particles have smooth edges and are less harmful to the human body. Therefore, tempered glass is also called safety glass.

(2) Risk of self-explosion:

1) Annealed glass:

There is generally no risk of self-explosion.

2) Tempered glass:

There is a certain risk of self-explosion. The main reason for self-explosion is the presence of impurities or stress concentration points inside the glass. During the tempering process, if the temperature is improperly controlled or the cooling is uneven, it may also cause self-explosion.

4.Annealed vs tempered glass——comparison of application scenarios

(1) Annealed glass:

1) Mainly used in situations that do not require high mechanical strength and safety, such as ordinary doors, windows, partitions, furniture glass, etc.

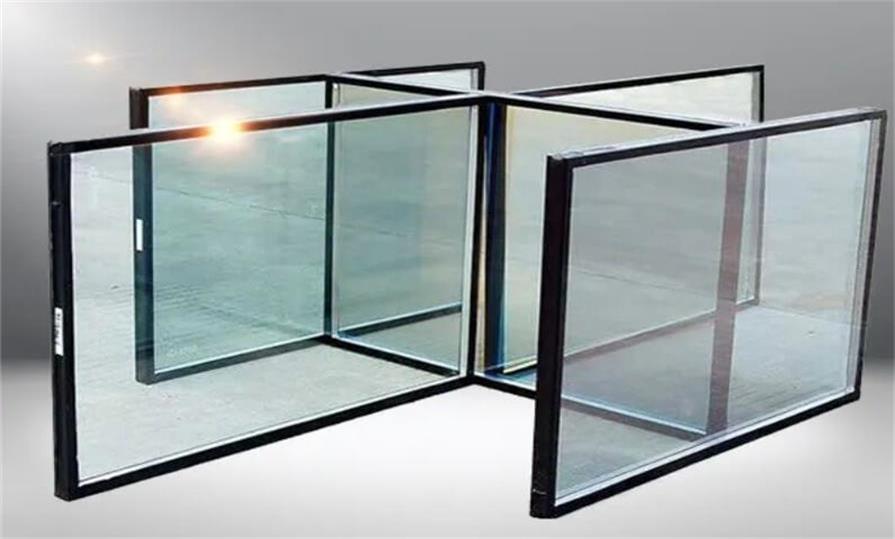

2) Annealed glass can also be used as a substrate for further processing, such as coated glass, laminated glass, insulating glass, etc.

(2) Tempered glass:

Due to its excellent mechanical properties, thermal stability and safety, it is widely used in the following fields:

1) Construction field: used in doors, windows, curtain walls, indoor partitions, floors, stair handrails, etc. of high-rise buildings.

2) Automobile field: used for front windshields, side windows, rear windshields, etc. of automobiles.

3) Furniture field: used for glass dining tables, glass coffee tables, glass cabinet doors, etc.

4) Electronic field: used for mobile phone screens, tablet computer screens, TV screens, etc.

5.Annealed vs tempered glass——cost and maintenance comparison

(1) Cost:

1) Annealed glass:

The production process is relatively simple and the cost is low.

2) Tempered glass:

Since it requires tempering treatment, the production process is relatively complex and the cost is high. Generally speaking, the price of tempered glass is 1.5-2 times that of annealed glass.

(2) Maintenance:

1) Annealed glass:

Maintenance is relatively simple, and surface scratches can be repaired through polishing and other methods.

2) Tempered glass:

Once damaged, it must be replaced as a whole, and processing such as cutting or drilling cannot be performed. Therefore, you need to pay more attention during installation and use to avoid collisions and scratches.

6.Annealed vs tempered glass——performance comparison summary

(1) Mechanical properties:

The mechanical strength of tempered glass is 3-5 times that of annealed glass, and its hardness is also higher. Therefore, in situations where it is necessary to withstand large impact forces and bending stresses, tempered glass should be preferred.

(2) Thermal stability:

The thermal stability of tempered glass is much better than that of annealed glass, and it can withstand greater temperature changes without cracking. Therefore, in environments with large temperature changes, such as ovens, microwave ovens, bathrooms, etc., tempered glass should be selected.

(3) Security:

When tempered glass breaks, it will form fine particles, which is less harmful to the human body. Therefore, in situations with higher safety requirements, such as building doors and windows, automobile glass, etc., tempered glass should be selected.

(4) Application scenarios:

Annealed glass is mainly used in situations where mechanical strength and safety are not required, such as ordinary doors, windows, partitions, furniture glass, etc. Tempered glass is widely used in construction, automobiles, furniture, electronics and other fields.

(5) Cost and maintenance:

Annealed glass is less expensive and relatively simple to maintain. The cost of tempered glass is higher, and once it is damaged, it must be replaced entirely, resulting in higher maintenance costs.

7.Annealed vs tempered glass——selection suggestions

(1) Choose according to the usage scenario:

If it is used for ordinary doors, windows, partitions, furniture glass and other occasions that do not require high mechanical strength and safety, you can choose annealed glass.

If it is used in high-rise building doors and windows, curtain walls, automotive glass, oven doors, microwave oven doors and other occasions that require high mechanical strength, thermal stability and safety, tempered glass should be selected.

(2) Select according to budget and maintenance cost:

If you are on a budget, you can opt for annealed glass.

If you have sufficient budget and can afford higher maintenance costs, you should choose tempered glass.

(3) Comprehensive consideration of security and performance:

When selecting glass, safety and performance should be considered. For occasions with higher safety requirements, tempered glass should be selected even if the cost is higher.

8.Summary:

Annealed glass and tempered glass each have their own characteristics and scope of application. When choosing, you should make a comprehensive consideration based on specific usage scenarios, budget, maintenance costs, security and performance requirements and other factors to make the most appropriate choice.