From depleted uranium bullets to piercing bullet amorphous: performance leap and environmental breakthrough

Although the use of depleted uranium bombs has improved the effectiveness of military strikes to a certain extent, the environmental risks and long-term health hazards it brings have become the focus of attention of the international community.

In contrast, piercing bullet amorphous not only performs well in performance, but also shows significant advantages in environmental safety. Piercing bullet amorphous is a new type of ammunition designed to take advantage of the unique properties of amorphous metal, showing important application potential in modern military technology.

This article will analyze in detail the necessity and feasibility of amorphous replacement of depleted uranium bombs for armor-piercing projectiles in terms of material properties, environmental impact and comprehensive performance.

1.Development and problems of depleted uranium bombs

Depleted uranium ammunition is a type of ammunition made from depleted uranium alloy. Depleted uranium is a by-product of uranium-235 refining nuclear fuel, and its main component is uranium-238. Depleted uranium alloy has the characteristics of high density, high hardness and self-sharpening properties, which makes depleted uranium bullets perform well when penetrating armor.

Therefore, depleted uranium bombs were widely used in the military field at the end of the 20th century, and the use of depleted uranium bombs greatly improved combat capabilities.

However, the use of depleted uranium bombs also brings a series of problems. The following is a detailed analysis of the problem:

(1) Environmental and health issues

The radioactive dust released when a depleted uranium bomb hits a target can cause serious contamination of soil, water and air. These radioactive substances exist in the environment for a long time and enter the human body through the food chain, possibly causing health problems such as cancer, leukemia, and hereditary diseases.

(2) International disputes

Due to the radioactive contamination of depleted uranium bombs, the international community has imposed strict restrictions on their use. International regulations clearly prohibit the use of weapons in war that cause long-term harm to the environment and human health.

2.The rise and application of amorphous materials

Amorphous materials, also known as metallic glasses, are materials with unique structures and properties. Unlike traditional crystalline materials, the atomic arrangement of amorphous materials is disordered, which gives them many excellent properties, such as high strength, high hardness, good toughness and corrosion resistance. In recent years, the application of amorphous materials in the military field has gradually received attention, especially in the manufacture of armor-piercing projectiles.

(1) Characteristics of amorphous materials

The disordered structure of amorphous materials gives them extremely high strength and hardness. Research shows that some amorphous materials can be several times stronger than traditional crystalline materials. In addition, amorphous materials also have good toughness and impact resistance, which allows them to absorb more energy when impacted and reduce the risk of shattering and fracture.

(2) Performance advantages of piercing bullet amorphous

Piercing bullet amorphous utilize the high strength and hardness of amorphous materials to more effectively penetrate modern armor. Compared with traditional depleted uranium bullets, piercing bullet amorphous are not inferior in penetration capabilities, and even perform better in some aspects. At the same time, the amorphous form of armor-piercing bullets does not contain radioactive substances, and the harm to the environment and human health is greatly reduced.

3.Performance leap from depleted uranium bullets to piercing bullet amorphous

The transformation from depleted uranium bullets to piercing bullet amorphous is not only a material substitution, but also a leap in performance. The amorphous state of armor-piercing projectiles shows significant advantages in the following aspects:

.

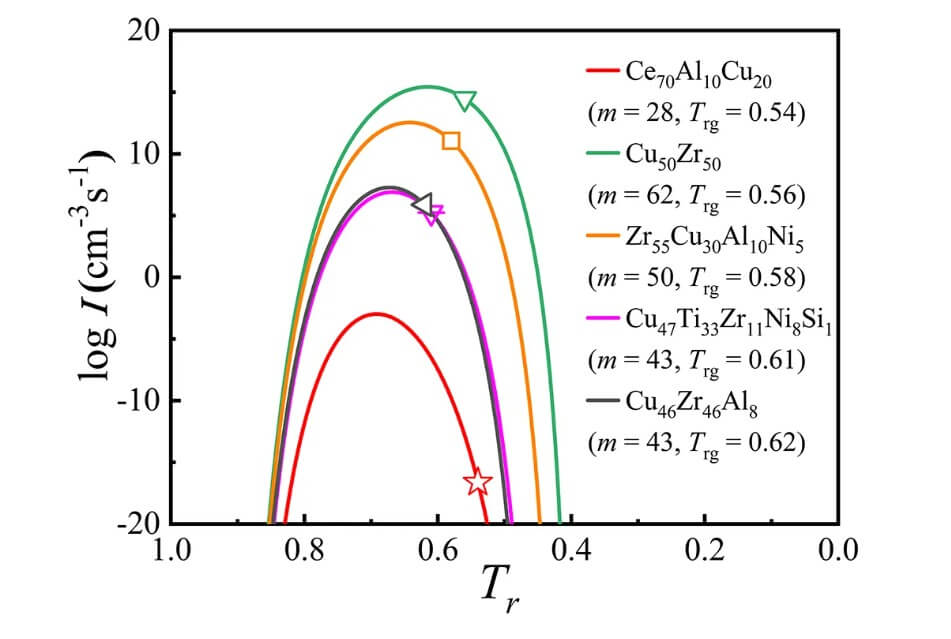

Verification of ultra-stability of amorphous alloys

.

(1) Great improvement in hardness and strength:

Amorphous alloys have extremely high hardness and strength, far exceeding the hardness of traditional metal alloys. This allows piercing bullet amorphous to more effectively penetrate the composite armor of modern tanks. Although depleted uranium bombs have a higher hardness, the hardness of amorphous materials has reached a new level.

(2) Excellent self-sharpening properties:

The amorphous alloy will adjust its microstructure when it is impacted. This characteristic allows it to maintain a sharp tip during the penetration process and continuously break through the armor’s defense.

(3) Better ballistic performance:

The uniformity and isotropy of amorphous materials give them more stable ballistic properties during flight. This means that armor-piercing projectiles can hit the target more accurately and improve strike efficiency. Due to limitations in material properties, the ballistic performance of depleted uranium bullets is relatively inferior to amorphous materials.

(4) Enhanced corrosion resistance:

Amorphous alloys have excellent corrosion resistance, which extends the storage life and reliability of armor-piercing projectiles to a certain extent. Although depleted uranium bombs also have good corrosion resistance, amorphous materials have better corrosion resistance.

4.What is the difference between amorphous armor-piercing bullets and depleted uranium bullets? Comprehensive analysis which one is better?

There are significant differences between piercing bullet amorphous and depleted uranium projectiles in many aspects. The following is a detailed explanation from five dimensions: material characteristics, armor-piercing performance, environmental impact, manufacturing process and cost, and strategic and legal considerations.

(1) Material properties

1) Piercing bullet amorphous state:

Made of amorphous metal, this material has high strength, high hardness and excellent ballistic properties. Its atomic arrangement is disordered and there are no grains or grain boundaries, giving the material unique mechanical properties.

2) Depleted uranium bomb:

Depleted uranium metal is mainly used as the core material. Depleted uranium has high density, self-sharpening effect and good armor-piercing ability. Its hardness changes little with temperature and can still maintain high hardness at high temperatures.

(2) Armor-piercing performance

1) Piercing bullet amorphous state

Piercing bullet amorphous can effectively penetrate modern composite armor due to their extremely high hardness and strength. Its armor-piercing mechanism mainly relies on the high crushing energy of the material under high-speed impact.

2) Depleted uranium bombs

The armor-piercing performance of depleted uranium bullets is also excellent. Its self-sharpening effect causes the bullet core to gradually become pointed during the penetration process, thereby increasing the armor-piercing depth. However, the armor-piercing performance of depleted uranium bullets is greatly affected by temperature and may not perform well in extreme environments.

(3) Environmental impact

1) Piercing bullet amorphous state

Amorphous alloy materials are relatively environmentally friendly and less harmful to the environment and human body.

2) Depleted uranium bombs

Depleted uranium bombs have serious radioactive contamination and chemical toxicity problems. Depleted uranium has low levels of radioactivity and produces toxic uranium oxide when burned, posing a long-term health risk to warfighters and local residents.

(4) Manufacturing process and cost

1) Piercing bullet amorphous state

The manufacturing process of amorphous alloys is relatively complex and requires rapid cooling and other technologies to convert liquid metal into an amorphous structure. However, with the advancement of technology and the expansion of production scale, its cost is gradually decreasing.

2) Depleted uranium bomb:

The manufacturing process of depleted uranium bombs is relatively simple, but the cost of obtaining and processing the raw material depleted uranium is high, and due to radioactive contamination issues, its subsequent processing and disposal costs are also considerable.

(5) Strategic and legal considerations

1) Piercing bullet amorphous state

As a high-performance and environmentally friendly ammunition, piercing bullet amorphous ammunition meets the needs of modern warfare for efficient and low-pollution weapons and has important strategic significance.

2) Depleted uranium bomb:

Due to the radioactive contamination of depleted uranium bombs, their use is strictly restricted by international and humanitarian law.

summary:

To sum up, the piercing bullet amorphous solves the problem of radioactive contamination of depleted uranium projectiles while maintaining high performance, and is more in line with the requirements of modern warfare for environmental and human protection. Therefore, the amorphous armor-piercing projectile is superior to the depleted uranium projectile in terms of comprehensive performance and environmental safety.

5.Basic principles and design of armor-piercing

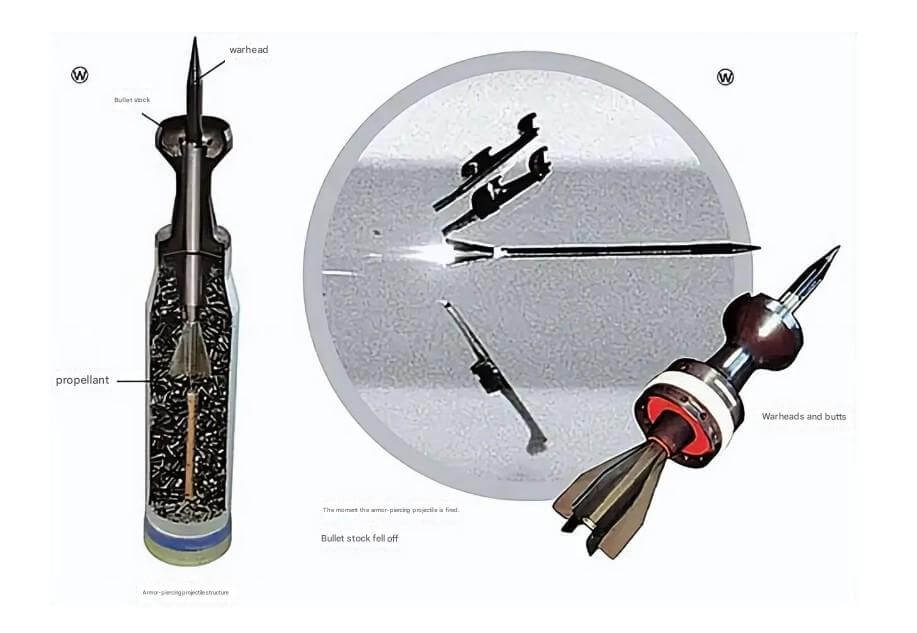

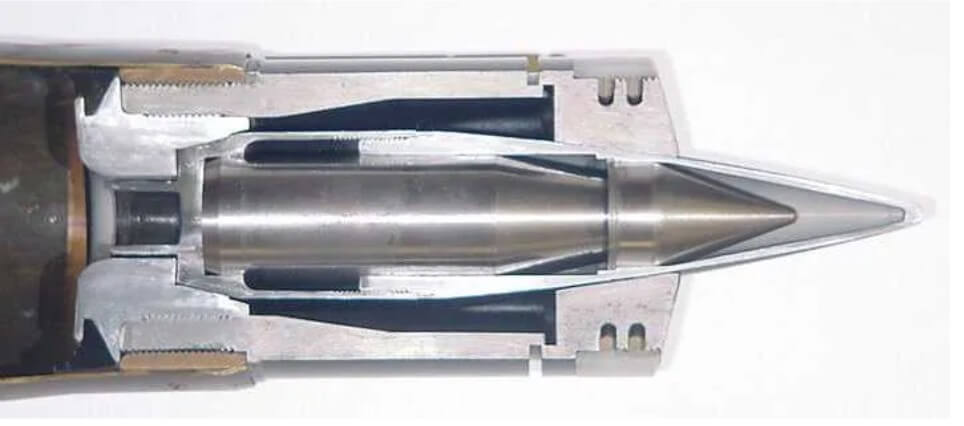

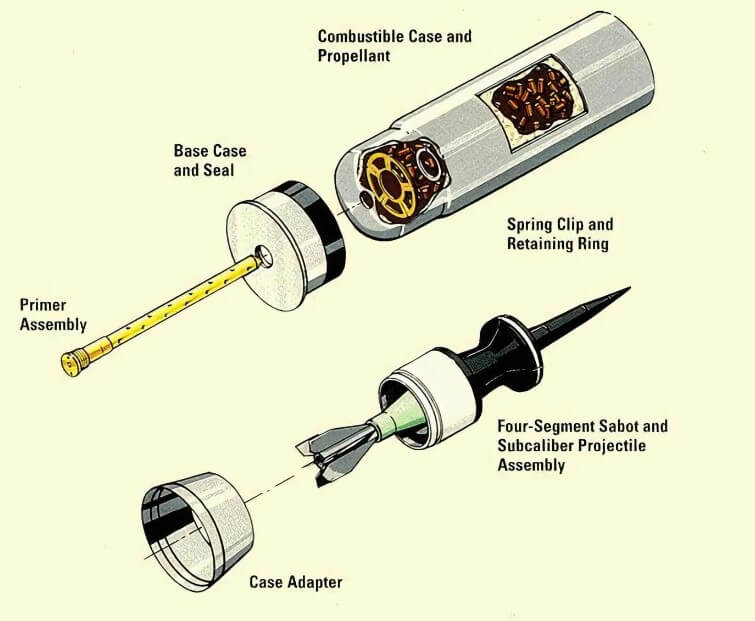

(1) Working principle of armor-piercing bullets

Armor-piercing projectiles mainly penetrate the target’s armor through the kinetic energy generated by their high-speed movement. When an armor-piercing projectile hits armor at high speed, its kinetic energy is converted into pressure energy, allowing the projectile to penetrate hard metal armor. This penetration ability mainly depends on the speed, hardness and design shape of the projectile. Additionally, the projectile needs to remain stable after penetrating the armor in order to cause maximum damage inside the target.

(2) Design elements of armor-piercing projectiles

When designing an armor-piercing projectile, several key elements need to be considered to ensure its effectiveness. The first is material selection. The projectile material must have high hardness and high strength to withstand the huge pressure during high-speed impact. Second is the structural design. The shape and size of the projectile have a direct impact on its flight stability and penetration ability. In addition, the surface treatment of the projectile is also extremely important. Special treatment can improve its wear resistance and corrosion resistance to ensure that the integrity is maintained during the penetration process.

6.Design and manufacturing of piercing bullet amorphous

(1) Material selection:

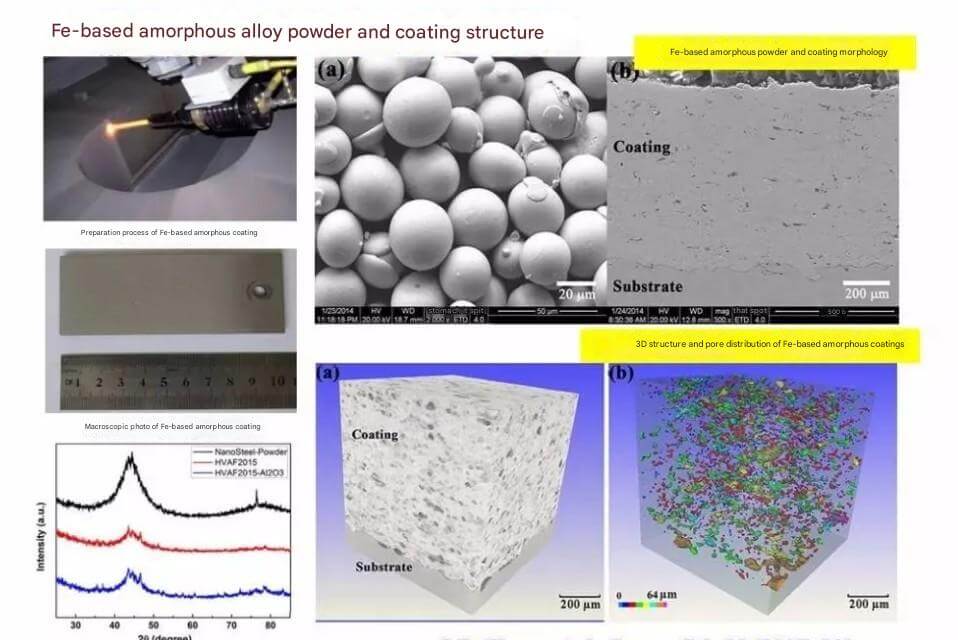

Amorphous alloys have high strength, high hardness and excellent corrosion resistance. Its microstructure is uniform and has no crystal defects, which enables the amorphous alloy to evenly disperse energy when impacted, avoiding brittle fracture caused by defects in traditional crystalline materials. Commonly used amorphous alloy materials include zirconium-based, copper-based and iron-based alloys.

For example, zirconium-based amorphous alloy has become an ideal material for armor-piercing bullet cores due to its ultra-high strength and good toughness. Its hardness can reach more than Hv1000, far exceeding traditional steel.

(2) Design principle:

The core of the amorphous state of armor-piercing bullets lies in the design of the bullet core. The bullet core is usually made of amorphous metal materials, using its high hardness and high strength properties to improve armor-piercing capabilities. The shape of the bullet core is designed to be slender to reduce the resistance when penetrating armor and optimize its aspect ratio to ensure that it can effectively penetrate enemy armor when hitting the target.

(3) Manufacturing process:

Amorphous alloys are usually formed using rapid solidification techniques such as injection molding or die casting. These techniques can cool molten metal to a solid state in a very short time, forming an amorphous structure. The cooling rate needs to be strictly controlled during the manufacturing process to avoid crystallization.

(4) Heat treatment:

Although amorphous metal itself has excellent mechanical properties, appropriate low-temperature heat treatment can further optimize its performance and improve the toughness and service life of the elastic core.

(5) Surface treatment technology:

A layer of wear-resistant and anti-oxidation coating, such as titanium nitride (TiN) or diamond-like carbon (DLC), is deposited on the surface of the amorphous alloy through physical vapor deposition (PVD) or chemical vapor deposition (CVD) technology to further improve The hardness and wear resistance of the bullet core.

7.Summary

The transition from depleted uranium bombs to piercing bullet amorphous is a manifestation of modern military technology’s pursuit of high performance while paying more attention to environmental protection and sustainable development. The emergence of amorphous armor-piercing bullets not only improves the performance of military equipment, but also makes important contributions to environmental protection.

What do you think?

There’s definately a great deal to learn about this issue.

I really like all the points you made.

I got this site from my buddy who told me concerning this web page and now this time I am browsing this web site

and reading very informative articles or reviews at this place.