Amorphous metal smart phones: light and tough

With the increasingly fierce competition in the smartphone market, major manufacturers are seeking breakthroughs in differentiated competition. As an emerging material, amorphous metal has become a new favorite of smartphone manufacturers with its excellent mechanical properties and unique processing characteristics.

Amorphous metal smart phones not only have higher strength and durability, but also can achieve more possibilities in design, bringing consumers a better product experience. This article will take you to explore the advantages, appearance design and manufacturing process, specific application components and the current popularity of amorphous metal smart phones in the market.

1.Definition and characteristics of amorphous metal

Amorphous metal, also known as metallic glass, is a material with a unique atomic structure. Unlike traditional crystalline metals, the atomic arrangement of amorphous metals does not have long-range order, but presents a disordered dense stacking state. This structure gives amorphous metals many excellent properties, including high strength, high hardness, excellent corrosion resistance, and good electrical and thermal conductivity. These characteristics make amorphous metals have broad application prospects in many high-tech fields.

2.Application prospects of amorphous metals in smart phones

With the continuous advancement of technology, the design and material selection of smartphones are also constantly evolving. Amorphous metals are gradually becoming one of the important materials in smartphone manufacturing due to their unique properties. Their high strength and high hardness can significantly improve the structural strength and durability of smartphones and reduce damage caused by accidental falls and collisions. In addition, the good electrical and thermal conductivity of amorphous metals can help improve the electronic performance and heat dissipation efficiency of smartphones, thereby improving the overall performance and user experience.

3.Advantages of amorphous metal smart phones

(1) High strength and lightweight

The high strength and hardness of amorphous metals enable smartphones to significantly improve their resistance to falling and crushing while maintaining a thin and light design. This is especially important for smartphones that are frequently carried and operated in daily use. The lightweight design not only improves the portability of the phone, but also makes the phone more comfortable during use. In addition, the density of amorphous metals is usually lower than that of traditional crystalline metal materials, which also helps to further reduce the weight of the phone.

(2) Corrosion resistance

The excellent corrosion resistance of amorphous metals can effectively protect the stable operation of smartphones in various harsh environments. Whether in a humid environment or in contact with various chemicals, amorphous metals can maintain stable performance. This is of great significance for improving the durability and service life of smartphones. Especially in some special environments, such as the seaside, high humidity areas or the chemical industry, the corrosion resistance of amorphous metal smartphones can better show its unique advantages.

(3) Excellent electrical and thermal conductivity

The good electrical conductivity of amorphous metals makes smartphones more advantageous in signal transmission and charging efficiency. This helps to improve the communication quality and charging speed of mobile phones. In addition, the thermal conductivity of amorphous metals is also very good, which can effectively help smartphones dissipate heat, protect internal components, and extend the service life of the device. Today, when high-performance processors and large screens have become standard features of smartphones, excellent thermal conductivity is particularly important for maintaining the stable operation of mobile phones and improving user experience.

4.Appearance design and manufacturing process of amorphous metal smart phones

(1) Streamlined appearance design

The streamlined appearance design of amorphous metal smart phones is not only beautiful, but also effectively improves the grip and operating experience. This design language makes the phone more modern and technological through simple lines and smooth curves. At the same time, the streamlined design can also reduce friction and wear during use, thereby improving the durability of the phone. In addition, the excellent processing performance of amorphous metal allows designers to be more free to carry out creative designs and achieve more diverse appearance effects.

(2) Manufacturing process

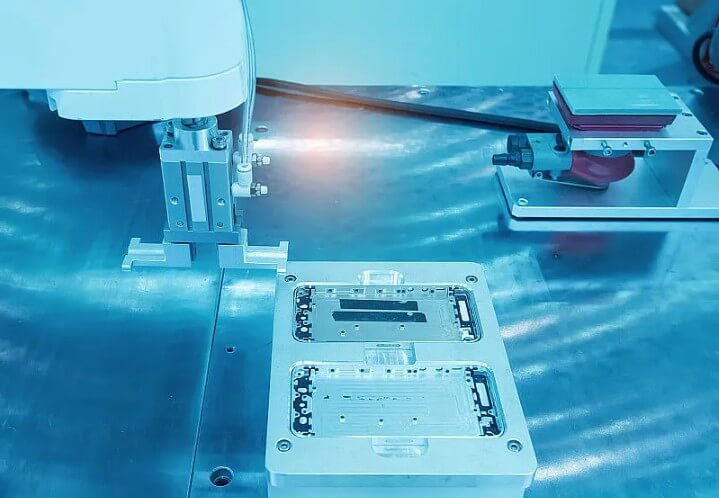

1) Precision casting technology

The shell of amorphous metal smart phones usually adopts precision casting technology, such as injection molding or die casting. These technologies can quickly cool the metal liquid to form an amorphous structure while ensuring the dimensional accuracy and surface finish of the shell. By optimizing the mold design and cooling system, the precise molding of complex structures can be achieved, meeting the dual requirements of smartphones for appearance and functionality.

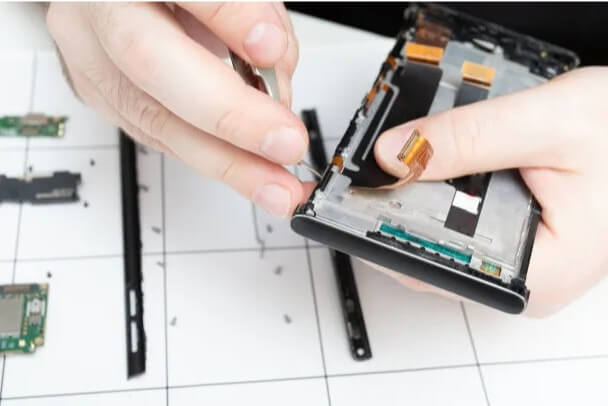

2) High-precision cutting and forming technology

The complex components in amorphous metal smart phones usually adopt high-precision cutting and forming technology. This technology allows manufacturers to perform precise processing at the micron level, ensuring that every detail of the phone case is perfect. High-precision cutting not only improves the appearance quality of the phone, but also ensures the assembly accuracy and overall performance of the phone. In addition, the forming technology of amorphous metal can also achieve complex three-dimensional structures, making the design of the phone more flexible and diverse.

(3) Surface treatment technology

Surface treatment of amorphous metal smart phones can provide them with a variety of visual effects and functions. For example, through special surface treatment technology, the surface of the phone can be made anti-fingerprint and anti-scratch. This not only improves the practicality of the phone, but also enhances the beauty of the phone. In addition, surface treatment technology can also achieve a variety of colors and texture effects, making the phone more personalized and attractive in appearance.

5.Specific components of amorphous metal smart phone applications

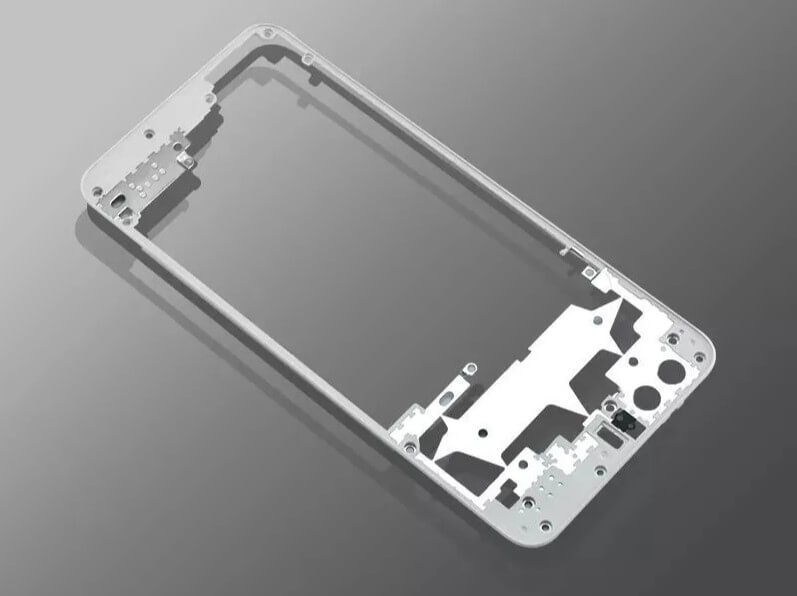

(1) Mobile phone shell:

Amorphous metal has high strength, high hardness and excellent corrosion resistance, making it very suitable for use as a shell material for smartphones. Compared with traditional metals, amorphous metal can be made into complex shapes through a one-time forming process, reducing production processes and reducing costs. At the same time, its smooth surface and unique texture can also enhance the appearance, texture and grade of the mobile phone.

(2) Connectors:

Smartphones have a compact internal structure. As an important component, connectors require high precision and miniaturization. Amorphous metals are ideal for manufacturing high-performance connectors due to their excellent mechanical properties and electrical conductivity. Amorphous metal connectors can withstand greater plug-in and pull-out forces, reduce signal transmission losses, and improve the connection reliability between internal components of mobile phones.

(3) Vibration motors:

The vibration motors in smartphones are used to achieve various tactile feedback. Amorphous metals can be used to manufacture key components of vibration motors, such as spring sheets, due to their high elasticity and good magnetic properties. This can significantly improve the response speed and vibration intensity of the vibration motor, thereby providing a clearer and stronger tactile feedback experience and enhancing the user’s interactive experience in gaming, input and other scenarios.

(4) Antenna components:

Amorphous metals have good electromagnetic properties and are increasingly used in smartphone antenna components. By using amorphous metals to manufacture key components such as antenna coils, the signal transmission efficiency of the antenna can be improved and the communication performance of the mobile phone can be enhanced. Especially in smartphones that support high-speed communication networks such as 5G, the advantages of amorphous metal antenna components are more obvious.

(5) SIM card tray:

Amorphous metal is also often used to make SIM card trays for smartphones. This is mainly due to its good wear resistance and deformation resistance, which can maintain stability and reliability during frequent insertion and removal of SIM cards, thereby extending the service life of the phone.

6.Summary of the current status of amorphous metal smart phones

Currently, amorphous metal smart phones have shown their unique competitiveness in the market, especially in durability and appearance design. However, high cost and manufacturing process challenges are still factors that restrict their wider popularization.

The high strength and high corrosion resistance of amorphous metal smart phones make them excellent in durability and can meet consumers’ demand for high-quality and high-performance products. At the same time, the excellent appearance and texture of amorphous metal also make smartphones more attractive in the market. However, the high production cost and complex manufacturing process of amorphous metal limit its popularity and application in the market.

7.Summary

With the continuous advancement of amorphous metal preparation technology and the further reduction of costs, its application prospects in smartphone production will be broader, and it is expected to bring more innovative designs and performance improvements to smartphones, and promote the market popularization and application of amorphous metal smart phones.