Amorphous alloys robotics: explorers of future technology

Amorphous alloys, as a material with a unique atomic structure, are gradually becoming the new favorite in the field of robot manufacturing.

Amorphous alloys robotics have broad application prospects in the fields of industry, medicine, deep sea, space, etc. This article will explore in depth the advantages, application fields, structural design and processing and manufacturing of amorphous alloys robotics, as well as the challenges to be faced. Let us understand how amorphous alloys have brought revolutionary breakthroughs to robot technology.

1.Explanation of related concepts of amorphous alloys robotics

(1) Definition and characteristics of amorphous alloys

Amorphous alloys, commonly known as metallic glasses, are materials with unique atomic structures. Unlike traditional crystalline alloys, the atomic arrangement of amorphous alloys has no long-range order and presents a disordered dense stacking state. This special atomic structure gives amorphous alloys a series of excellent physical and chemical properties, including high strength, high hardness, excellent corrosion resistance and high elastic limit. These properties make amorphous alloys have great potential in many demanding application fields.

(2) Application of robots in modern science and technology

As one of the most representative high-tech fields in the 21st century, robotics has penetrated into all aspects of human life. From industrial production to medical surgery, from home services to exploring unknown areas, the application of robots is everywhere. In the industrial field, robots are widely used in automated production lines, greatly improving production efficiency and product quality. In the medical field, surgical robots can perform high-precision minimally invasive surgery, reducing patients’ pain and recovery time. In the exploration field, robots are used in space exploration and deep-sea exploration, expanding the boundaries of human cognition.

2.Advantages of amorphous alloys in robot manufacturing

Amorphous alloys have excellent performance due to their unique atomic structure and are emerging in the field of robot manufacturing. The following are several major application advantages of amorphous alloys in robot manufacturing:

(1) High strength and high hardness:

Amorphous alloys have strength and hardness far exceeding traditional crystalline alloys. This makes robot components more durable and able to withstand greater impact and load, improving the robot’s ability to operate in harsh environments. For example, robot joints and arms made of amorphous alloys are not only lighter, but can also withstand higher mechanical stress and extend their service life.

(2) Excellent corrosion resistance:

Many amorphous alloys have excellent corrosion resistance and can remain stable in extreme environments. This is especially important for robots that need to work in corrosive environments such as chemicals and oceans, which can effectively reduce maintenance costs and extend the service life of robots.

(3) High elasticity and flexibility:

The high elasticity of amorphous alloys enables robot parts to produce large elastic deformations when subjected to force without permanent deformation, thereby improving the flexibility and safety of robots. This property is particularly important for the manufacture of bionic robots or robots that require high-precision operations.

(4) Excellent magnetic properties:

Some amorphous alloys have excellent magnetic properties, such as high magnetic permeability and low magnetic loss. This gives amorphous alloys significant advantages in the manufacture of robot sensors, actuators and other components, which can improve the robot’s perception ability and control accuracy.

(5) Good processing performance:

Amorphous alloys can be made into various shapes such as thin strips and plates through rapid cooling processes, which is convenient for processing and manufacturing of robot parts. In addition, amorphous alloys have a low work hardening rate and are easy to perform precision processing and molding, meeting the robot’s demand for high-precision parts.

(6) Lightweight design:

The density of amorphous alloys is generally lower than that of traditional alloys, achieving lighter weight of parts with the same strength. This helps robots achieve lightweight design, reduce energy consumption, and improve movement speed and efficiency.

(7) Excellent wear resistance:

The high hardness and dense structure of amorphous alloys give them excellent wear resistance, reducing the frequency of replacement of robot parts due to wear and reducing maintenance costs.

3.Application fields of amorphous alloys robotics

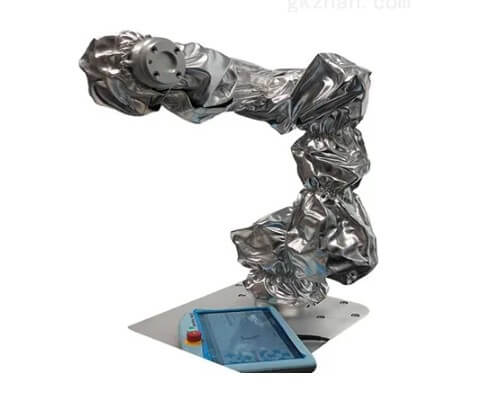

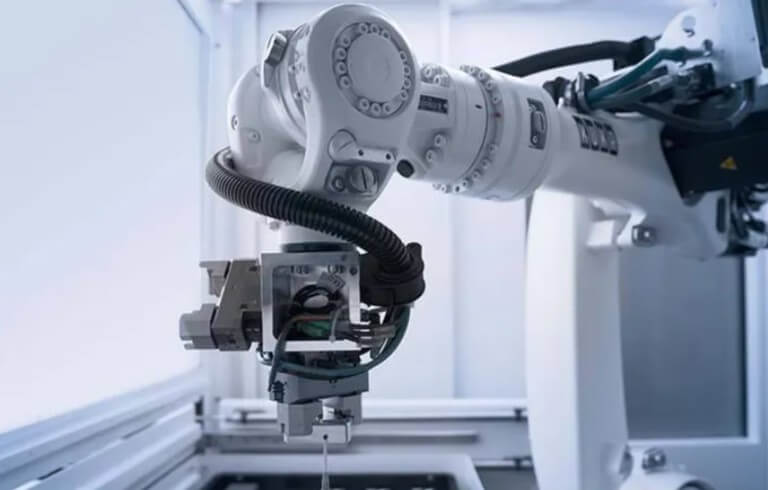

(1) Industrial field

In the field of industrial automation, amorphous alloys robotics are widely used in precision manufacturing and automated production lines due to their high strength and durability. These robots are able to perform high-precision processing tasks such as micro-machining and precision assembly, and can operate stably for a long time in harsh environments, greatly improving production efficiency and product quality. In addition, the high elastic limit of amorphous alloys robotics makes them more flexible during operation, able to adapt to different production needs, and reduce the time for equipment adjustment and maintenance.

For example, in the semiconductor manufacturing process, amorphous alloys robotics can be used for high-precision lithography and etching operations to ensure the quality and performance of chips. In the automobile manufacturing process, amorphous alloys robotics can be used for welding and painting operations to improve the efficiency and stability of the production line. In the aerospace manufacturing process, amorphous alloys robotics can be used for high-precision processing and assembly operations to ensure the quality and safety of parts.

(2) Medical field

The application of amorphous alloys robotics in the medical field also shows great potential. Due to the excellent biocompatibility and corrosion resistance of this material, amorphous alloys robotics are very suitable for the manufacture of medical equipment and surgical tools. For example, minimally invasive surgical robots can use the high precision and high elasticity of amorphous alloys to perform more delicate surgical operations, reducing patient trauma and recovery time. In addition, rehabilitation robots can also use the characteristics of amorphous alloys to provide more stable and accurate rehabilitation training to help patients recover function faster.

For example, the da Vinci surgical system is a surgical robot that uses amorphous alloy materials. It can perform high-precision surgical operations through tiny incisions, reducing patients’ pain and recovery time. In the field of rehabilitation, amorphous alloys robotics can be used to manufacture intelligent prostheses and rehabilitation equipment, provide more personalized and precise rehabilitation training, and help patients recover their motor and sensory functions.

(3) Exploration and rescue

In the field of exploration and rescue, the application of amorphous alloys robotics is also increasing. These robots can be used in extreme environments such as space exploration and deep-sea exploration. Since amorphous alloys can maintain stability at extreme temperatures, these robots are more reliable in extreme environments. For example, space exploration robots can perform complex tasks under extreme temperature and radiation conditions, while deep-sea exploration robots can work for long periods of time in high-pressure and corrosive environments.

For example, the Curiosity Mars Rover is an exploration robot that uses amorphous alloy materials. It has been exploring the surface of Mars for many years and has provided a large amount of valuable data and images. In the field of deep-sea exploration, amorphous alloys robotics can be used to explore deep-sea hydrothermal vents and seabed mineral resources, providing high-resolution data and images to help scientists understand the deep-sea environment.

4.Structural design and manufacturing of amorphous alloys robotics

(1) Structural design

1) Lightweight design:

Use the high strength characteristics of amorphous alloys to design thin-walled structures, reduce the overall weight of the robot, and improve movement efficiency and flexibility.

Optimize the structural layout and use topological optimization methods to reduce material usage while ensuring strength and stiffness.

2) Integrated design:

Use integrated molding technology to reduce the number of parts, simplify the assembly process, and improve the overall stiffness and precision of the robot.

Design multifunctional integrated components, integrate sensors, actuators and other functions into structural parts, and realize functional integration and modularization.

3) Environmental resistance design:

For harsh environment applications, use the corrosion resistance and magnetism of amorphous alloys to design a robot structure with a high protection level.

Use sealing design and protection measures to ensure the reliable operation of the robot in harsh environments such as high humidity and corrosive gases.

(2) Processing and manufacturing

1) Precision casting:

Using the rapid solidification characteristics of amorphous alloys, precision casting technologies such as injection molding and die casting are used to achieve high-precision and complex-shaped parts manufacturing.

Optimize casting process parameters and control cooling speed to ensure the formation of amorphous structure and stable performance.

2) Cutting:

For parts that require higher precision, cutting methods such as CNC machining and grinding are used.

Select appropriate tools and processing parameters, control cutting force and cutting temperature, and avoid damage to amorphous structure.

3) Surface treatment:

Use surface treatment technologies such as coating and plating to further improve the wear resistance, corrosion resistance and other special properties of amorphous alloy robot parts.

Optimize surface treatment process to ensure uniformity and bonding strength of coating or plating.

5.Challenges and future development directions of amorphous alloys robotics

(1) Cost issues

Although amorphous alloys robotics have many advantages, the high cost of their manufacturing process is still a major challenge. The production of amorphous alloys involves complex processes and high-cost raw materials, which directly increases the manufacturing cost of robots and limits their large-scale application. How to reduce production costs is a key issue in the development of amorphous alloy robot technology.

To solve this problem, researchers are exploring new manufacturing processes and materials. For example, by optimizing the cooling rate and alloy composition, the production cost of amorphous alloys can be reduced. In addition, the use of 3D printing technology can reduce material waste and improve production efficiency, thereby reducing manufacturing costs. Through these technological innovations, the production cost of amorphous alloys robotics can be gradually reduced, promoting their large-scale application.

(2) Technical limitations

At present, the technical limitations of amorphous alloys robotics are mainly reflected in the complexity of material processing and heat treatment. The processing of amorphous alloys usually requires special equipment and processes, which increases the difficulty and time of manufacturing. In addition, the heat treatment of amorphous alloys also needs to be precisely controlled to avoid the degradation of material properties. These technical limitations have a certain impact on the performance and application range of amorphous alloys robotics.

To overcome these technical limitations, researchers are developing new processing and heat treatment methods. For example, the use of high-precision casting processes and CNC machine tools can improve the processing efficiency and quality of amorphous alloys. In addition, by optimizing the heat treatment process, the performance and stability of amorphous alloys can be improved, thereby expanding their application range.

(3) Market acceptance

Although the performance of amorphous alloys robotics is superior, it still takes time for the market to accept them. On the one hand, users do not have enough knowledge of this new material and new technology, and may be conservative about its performance and reliability; on the other hand, the high cost of amorphous alloys robotics also affects the market promotion and acceptance. Therefore, improving market acceptance is an important task in the development of amorphous alloy robot technology.

6.Summary

As amorphous alloy technology continues to mature, robots will become more flexible, efficient and intelligent. Amorphous alloys robotics not only break through the constraints of traditional materials, but also open up a new path for the development of robot technology. In the future, they will continue to shine in the fields of manufacturing, medical care, exploration, etc.

What do you think?

[…] Amorphous metal, also known as metallic glass, is a material with a unique atomic structure. Unlike traditional crystalline metals, the atomic arrangement of amorphous metals does not have long-range order, but presents a disordered dense stacking state. This structure gives amorphous metals many excellent properties, including high strength, high hardness, excellent corrosion resistance, and good electrical and thermal conductivity. These characteristics make amorphous metals have broad application prospects in many high-tech fields. […]

[…] steel, as a new type of material, has become a hot spot in many fields due to its high strength, high hardness, excellent soft magnetic properties and good corrosion […]

[…] (3) Intelligent fields such as robotic manufacturing […]