Bulk metallic glass applications: Innovative materials for high-end components

Today, the practice of bulk metallic glass applications continues to diversify and expand. In addition to medical, electronics, aerospace, military, sports, precision instruments and other fields, it is now also emerging in new energy, smart devices and other emerging fields.

In this paper, we will discuss the topic of bulk metallic glass application in depth, in which we will list the characteristics of bulk metallic glass and the application areas applicable to its characteristics, and analyze the current status of its application, challenges and future trends.

1.Introduction to the basic concept of bulk metallic glass

Bulk metallic glass, also known as amorphous alloy, is a metal material without a lattice structure. Compared with traditional crystalline metals, it has higher strength and better corrosion resistance. This material is formed by rapid cooling technology, and its atomic arrangement is disordered, similar to glass, hence the name metallic glass.

2.Exploring the background and significance of bulk metallic glass application

As a new type of material, bulk metallic glass has many unique properties, such as high strength, high hardness, excellent elastic limit and good corrosion resistance. These characteristics make the application of bulk metallic glass have broad and important prospects.

The emergence of bulk metallic glass has broken the design and application limitations of traditional materials. Its high strength and hardness make it an ideal material for manufacturing high-strength parts, and it has wide application potential in aerospace, military and other fields. At the same time, its excellent elastic limit and corrosion resistance also make it show unique advantages in medical devices, electronic products and other fields.

The application of bulk metallic glass not only helps to promote the development of related industries, but also promotes the innovation and progress of new material technology, providing strong support for the development of science and technology.

3.Classification of bulk metallic glass

(1) Precious metal-based bulk metallic glass:

This type of metallic glass is usually based on precious metals such as palladium, gold, silver, etc., and has excellent amorphous forming ability and good physical properties. However, due to the high cost of precious metals, this type of material is mainly used in scientific research.

(2) Rare earth-based bulk metallic glass:

Based on rare earth elements such as lanthanum and cerium, this type of metallic glass has good magnetic properties and high temperature stability, and is suitable for applications in special environments.

(3) Zirconium-based bulk metallic glass:

Zirconium-based alloys have attracted attention due to their high strength and good corrosion resistance. This type of metallic glass usually contains elements such as zirconium, aluminum, nickel, and copper, and is widely used in aerospace and biomedical fields.

(4) Magnesium-based bulk metallic glass:

Magnesium-based metallic glass has potential due to its light weight and high strength. It usually contains elements such as magnesium, copper, and yttrium, and is suitable for the automotive and electronics industries.

(5) Iron-based bulk metallic glass:

Iron-based metallic glass has low cost and excellent soft magnetic properties. It usually contains elements such as iron, cobalt, silicon, and boron, and is widely used in electronic components.

4.Analysis of different properties of bulk metallic glass applications

Bulk metallic glass exhibits many excellent properties due to its unique amorphous structure. Different properties are suitable for different application fields. The following is a detailed analysis of its main properties:

(1) High strength and high hardness:

Due to the disordered arrangement of its internal atoms, bulk metallic glass has no obvious defects such as grain boundaries and dislocations, which makes it have higher strength and hardness than traditional crystalline metals. This characteristic makes bulk metallic glass have great potential as a structural material and can withstand greater loads and pressures.

(2) Excellent elasticity:

Its elastic limit is much higher than that of traditional metals, which means that when subjected to force, it can withstand greater deformation without plastic deformation. This excellent elastic property gives bulk metallic glass a great advantage when used as elastic elements such as springs and shock absorbers.

(3) High corrosion resistance:

Due to its low surface energy and the absence of defects such as grain boundaries that are prone to corrosion, bulk metallic glass has extremely high corrosion resistance. This property makes it an ideal material choice in harsh environments such as chemical and marine fields.

(4) Good soft magnetic properties:

Some bulk metallic glasses have excellent soft magnetic properties, such as high magnetic permeability and low coercivity. This makes them have broad application prospects in electronic devices, sensors and other fields.

(5) Thermal stability:

Bulk metallic glass can maintain its structural stability at high temperatures and is not prone to crystallization transformation. This thermal stability makes its application in high temperature environments possible, such as as high temperature structural materials or thermal protection materials.

(6) Processing performance:

Bulk metallic glass can be processed and formed by processes such as superplastic forming, which facilitates the manufacture of parts with complex shapes. At the same time, it has high processing accuracy and good surface quality, which can meet the needs of high-precision applications.

5.Bulk metallic glass application

As a new type of material, bulk metallic glass has shown broad application prospects in many fields due to its unique properties. The following are several key areas of bulk metallic glass application:

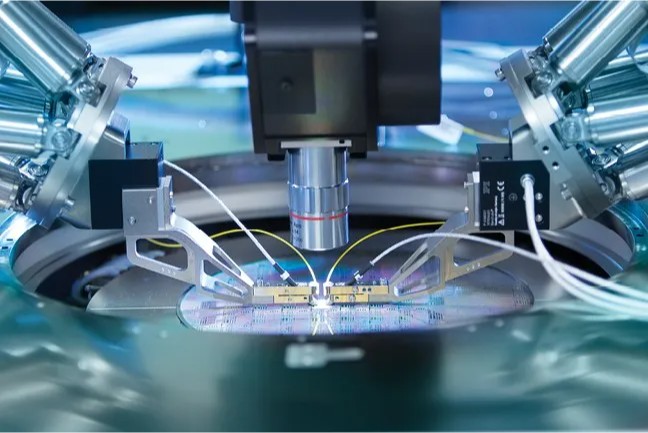

(1) Precision machinery

In precision machinery manufacturing, the high precision and excellent mechanical properties of bulk metallic glass make it an ideal material for manufacturing high-precision instruments. For example, micro motors made of bulk metallic glass are not only highly accurate, but also have a lifespan far exceeding that of parts made of traditional materials. The smooth surface and dimensional stability of bulk metallic glass give it unique advantages in precision machinery manufacturing.

(2) Sports equipment

The high strength and light weight of bulk metallic glass have led to its increasing application in the manufacture of sports equipment. For example, the use of bulk metallic glass can significantly improve the performance and durability of sports equipment such as golf clubs, bicycle frames and skis. Sports equipment made of bulk metallic glass is not only lightweight and durable, but also provides a better sports experience.

(3) Aerospace

In the aerospace field, the light weight, high strength and excellent fatigue resistance of bulk metallic glass make it an ideal material for manufacturing aircraft and spacecraft components. These properties help reduce the weight of aircraft and improve fuel efficiency and flight performance. Aerospace applications of bulk metallic glass include wing leading edges, engine components, etc., which can maintain stable performance in extreme environments.

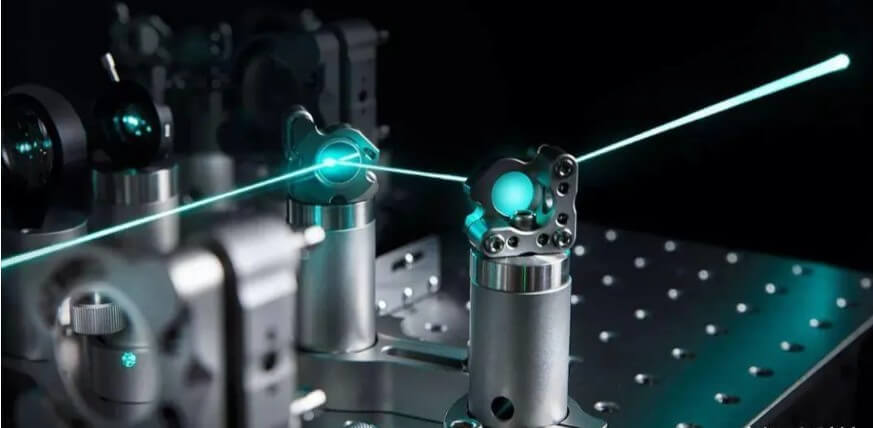

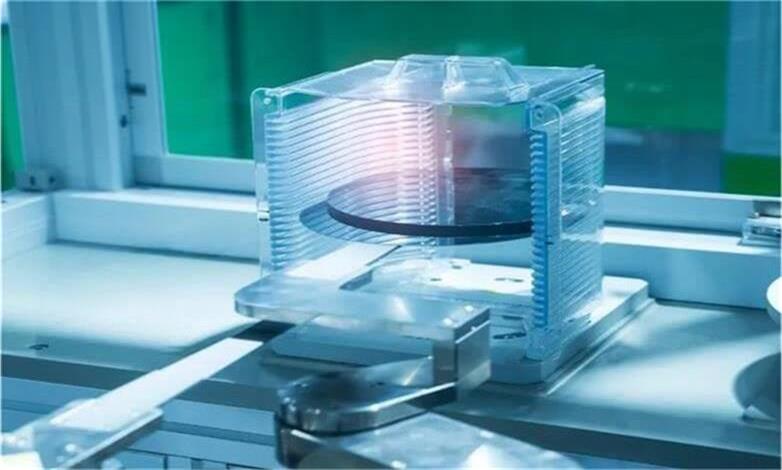

(4) Electronic information

The bulk metallic glass application also includes the electronic information field, especially in the manufacture of high-performance magnetic materials and electronic equipment casings. For example, iron-based bulk metallic glass is used to manufacture high-efficiency transformers and sensors due to its excellent soft magnetic properties. The electronic information applications of bulk metallic glass also include high-performance storage devices and microelectronic devices, which can provide excellent magnetic and mechanical properties.

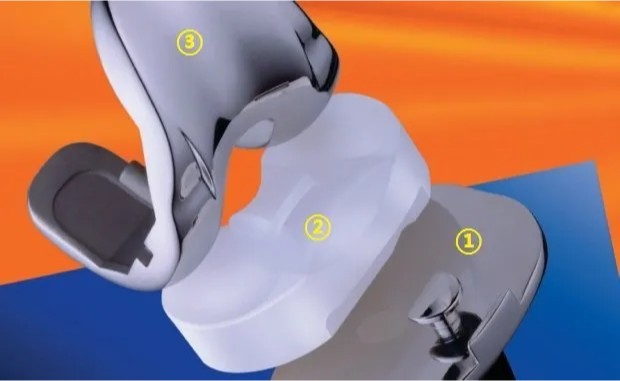

(5) Biomedicine

In the biomedical field, the biocompatibility and corrosion resistance of bulk metallic glass make it an ideal material for manufacturing implants. For example, it can be used to manufacture artificial joints, dental implants, etc., because it will not have adverse reactions with human tissues and can exist stably in the human body for a long time. In addition, bulk metallic glass can also be used to manufacture surgical tools and medical equipment. Due to its high strength and hardness, it can improve the service life and performance of the tools.

(6) Military field

The bulk metallic glass application in the military field is mainly due to its excellent mechanical properties. Compared with traditional metals, bulk metallic glass has higher strength and hardness, which makes it have great potential in the manufacture of protective equipment. For example, it can be used to make bulletproof vests, bulletproof helmets, etc., which can significantly improve the protective ability of equipment and ensure the safety of soldiers.

6.Challenges and future development directions of bulk metallic glass applications

(1) Cost control and large-scale production

Although bulk metallic glass has many superior properties, its production cost is relatively high, which limits its wide application. Future research will focus on developing more cost-effective production methods to achieve large-scale production.

(2) Performance optimization and new material development

Continuing to optimize the performance of bulk metallic glass, such as improving its toughness and developing new materials with specific functions, is an important direction for future research. This will expand its application range and market share.

(3) Expanding application areas and markets

With the advancement of technology and the growth of market demand, the bulk metallic glass application is expected to expand further, especially in emerging fields such as renewable energy, electric vehicles and smart devices.

What do you think?

[…] 3.Application areas of aerospace amorphous […]