Cast iron skillet: how is it cast?

Cast iron skillets are usually made through the casting process. Casting is an ancient hot metal working process that involves pouring liquid metal into a casting cavity that corresponds to the shape of the part and leaving it to cool and solidify in order to obtain a part or blank. In this paper, we will discuss in depth the advantages and disadvantages of cast iron skillet, production process, common surface treatment process, manufacturing and use of common problems and solutions.

1. Basic knowledge of cast iron skillet:

(1) Material and process:

Cast iron skillet made of iron carbon alloy with carbon content of more than 2%, by melting and then mold casting into a pot, this process has been used for more than a hundred years, creating many centuries-old brands.

(2) Advantages:

1) strong heat storage capacity: cast iron skillet ‘s thick walls provide high heat capacity, which is conducive to the frying of large ingredients and can stabilize the temperature of the pan.

2) High temperature resistance: the melting point of cast iron is up to 1500 ℃ or more, suitable for high temperature cooking.

3) Physical non-stick: With use and care, a natural non-stick coating will form on the surface of the skillet.

4) Sturdy and durable: cast iron is a very sturdy material, and a well-maintained cast iron skillet can last for years.

(3) Disadvantages:

1) greater weight: the same caliber cast iron skillet is usually more than twice the weight of a cooked iron skillet.

2) relatively poor thermal conductivity: it takes a long time to heat to reach the target temperature.

2. Cast iron skillet casting process

Cast iron skillet is a common cooking tool, favored by many chefs for its excellent heat conductivity and durability. The following is an introduction to the cast iron skillet casting process:

(1) Mold making:

First of all, a mold with the same shape as the skillet needs to be made. The mold is usually made of high-temperature resistant materials, such as sand or metal type. The quality of the mold directly affects the accuracy and surface finish of the final product.

(2) Melting iron:

Pig iron and other alloying materials (e.g. carbon, silicon, manganese, etc.) are put into a melting furnace and heated to a high temperature so that they are completely melted. The composition and temperature of the molten iron are critical to the performance of the cast iron skillet.

(3) Pouring:

Pour the melted iron into the preheated mold. The temperature and flow rate of the molten iron need to be controlled during the pouring process to ensure that the molten iron can evenly fill all corners of the mold.

(4) Cooling and solidification:

After pouring, the molten iron is cooled and solidified in the mold. This process takes some time, depending on the size and thickness of the skillet.

(5) Demolding and cleaning:

After the frying pan has completely solidified, it is removed from the mold and cleaned to remove sand, burrs and other impurities from the surface.

(6) Heat treatment:

In order to improve the mechanical properties and wear resistance of the frying pan, appropriate heat treatment, such as annealing or normalizing, is usually required.

(7) Surface treatment:

Surface treatments such as grinding and polishing are applied to the frying pan to improve its aesthetics and service life. Some frying pans are also subjected to surface coating treatment to prevent rust and improve nonstick properties.

(8) Quality inspection:

The casting of the completed frying pan for quality inspection, including size inspection, surface quality inspection, mechanical properties test, etc., to ensure that the product meets the relevant standards and requirements.

3. Cast iron skillet common surface treatment process

In order to enhance the performance and service life of cast iron skillet, a variety of surface treatment processes are usually used. The following are several common surface treatment processes:

(1) Nitriding treatment:

Nitriding is a chemical heat treatment process, by infiltrating nitrogen atoms into the surface of cast iron at high temperatures to form a hard nitride layer. This process can significantly improve the wear resistance and corrosion resistance of cast iron skillet. The surface of the frying pan after nitriding treatment is gray-black, high hardness and long service life.

(2) Oxidation treatment:

Oxidation treatment is by placing the frying pan in a high-temperature environment, so that its surface generates a dense layer of oxide film. This layer of oxidized film can effectively prevent the frying pan from rusting, and improve its heat resistance. The surface of the frying pan after oxidation treatment is usually dark gray or black.

(3) Salt-pulling treatment:

Salt pulling treatment is a special surface treatment process, by applying a layer of salt solution on the surface of the frying pan, and then heat treating it under high temperature, so that the salt and cast iron surface chemical reaction, forming a protective film. This protective film can effectively prevent the skillet from rusting and improve its corrosion resistance.

(4) Oil coating treatment:

The oiling treatment is a simple surface treatment process, by coating the surface of the frying pan with a layer of edible oil, and then heating it at a high temperature, so that the edible oil forms a protective film on the surface of the cast iron. This protective film can effectively prevent the skillet from rusting and improve its non-stick properties. The surface of the frying pan after oiling is usually black or dark gray.

(5) Enameling:

Enameling is a process of coating the surface of the frying pan with a layer of enamel glaze, which is fired at a high temperature to make the enamel glaze closely bonded to the surface of the cast iron. Enameling treatment of the frying pan surface smooth and beautiful, easy to clean, at the same time has good corrosion resistance and non-stick.

4. Cast iron skillet in the casting process of common defects and measures to solve them

(1) Gas hole defects:

In the casting process, if the gas fails to escape in time, it may form porosity inside the casting.

Solution measures include improving the temperature of the liquid iron casting, reasonable setting of the location and size of the sprue, increase the exhaust risers, so that the liquid iron flows smoothly so that it can quickly fill the cavity.

(2) Shrinkage and shrinkage holes:

This phenomenon usually occurs in the casting thick section or hot section, due to the liquid metal in the cooling solidification of the liquid contraction and solidification contraction is much larger than the solid state contraction, and in the casting of the last solidified place can not get the liquid metal supplement caused.

Solution measures include improving the casting strength, reasonable increase in the weight of the press box iron, reasonable setup of complementary shrinkage risers size and location.

(3) Crack defects:

Cracks may be caused by the strength of the metal material is difficult to support the metal in the cooling solidification contraction stress.

Solution measures include strict control of the chemical composition of the liquid iron, especially the content of carbon and silicon, as well as the rational design of the pouring system, to avoid the liquid iron on the mold wall scouring force is too large.

(4) Cold segregation defect:

Cold segregation refers to the pouring of liquid iron, due to splashing, pouring interruptions or from different directions of the two metal streams meet, the liquid metal surface cooling the formation of semi-solid film remains in the cast iron parts and the formation of a diaphragm-shaped area defects.

Solution measures include improving the pouring temperature, to ensure that the pouring process is continuous, to avoid the cooling of the metal flow encounter.

(5) inclusions (slag) defects:

Inclusions (slag) is a common defect in cast iron, the source of which mainly includes slag, oxides, paint flakes, sand and so on.

The solution measures include improving the degree of refining of the molten iron, improving the slag blocking capacity of the pouring system, improving the strength of the sand mold (core), preventing paint flaking, strictly controlling the hot air baking temperature and time, operating carefully and meticulously, removing the sand particles, dust and other debris scattered in the casting, appropriately adjusting the amount of machining of the casting’s side and top surfaces, as well as strictly controlling the pouring temperature.

5. Cast iron skillet in the use of common problems and measures to solve them

(1) Cracking:

Cast iron skillet may crack due to physical impact or sudden temperature change. Once cracks are found, they should be stopped immediately as they may expand and cause safety hazards.

(2) Warping:

Too rapid a change in temperature may cause the skillet to warp. Avoid placing a hot skillet in cold water or heating it too quickly to ensure even heating of the skillet.

(3) Hole formation:

Prolonged use and improper maintenance may cause small holes or pits to form in the surface of the skillet. These damages are usually not repairable and replacement with a new skillet is recommended.

(4) Damage to enamel coating:

For enameled cast iron skillets, the enamel coating may become damaged or worn over time. Avoid dishwasher cleaning and metal tools to minimize damage to the coating.

(5) Sticky skillets:

Cast iron skillets that are not adequately preheated may cause food to stick to the pan. Ensure that the skillet is adequately preheated before cooking and that an oil film forms on the surface to minimize sticking.

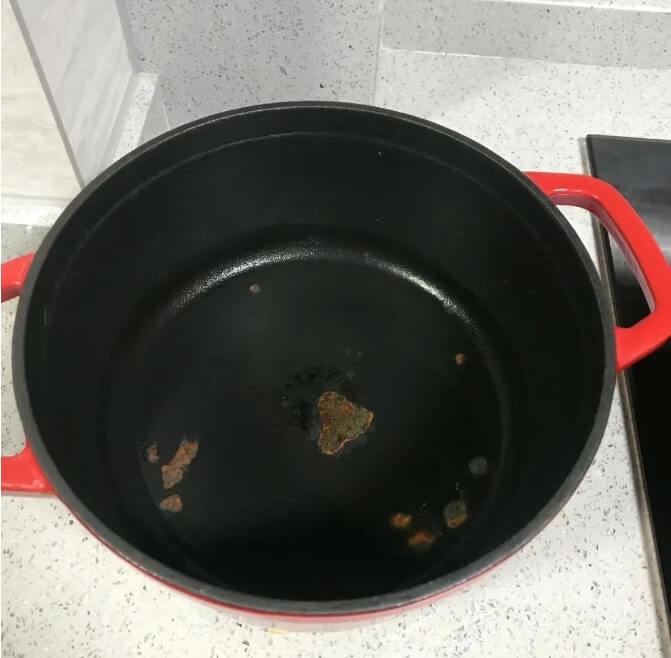

(6) Rust:

Cast iron skillets are prone to rusting if not properly maintained. It should be thoroughly cleaned and dried after use, then coated with a thin layer of cooking oil to prevent rusting.

6. Summary

The best feature of cast iron skillet is its excellent heat capacity and even heat distribution. Due to the nature of the cast iron material, the skillet is able to store a large amount of heat and transfer it evenly to the food during the cooking process. This characteristic allows the skillet to quickly develop a deliciously browned surface while keeping the interior of the ingredients moist and tender.