Investment casting medical devices: advantages, applications and challenges

As a key support for precision medicine, investment casting medical devices technology meets the requirements of modern medical treatment for equipment refinement and high performance. The medical devices made by this technology not only can perfectly fit the human body structure in form, but also can realize more accurate treatment effect in function, which greatly improves the success rate of diagnosis and treatment. In this paper, we will discuss the advantages of investment casting medical devices, application areas, as well as the technical challenges and solutions.

1.Basic knowledge of investment casting medical devices

(1) investment casting

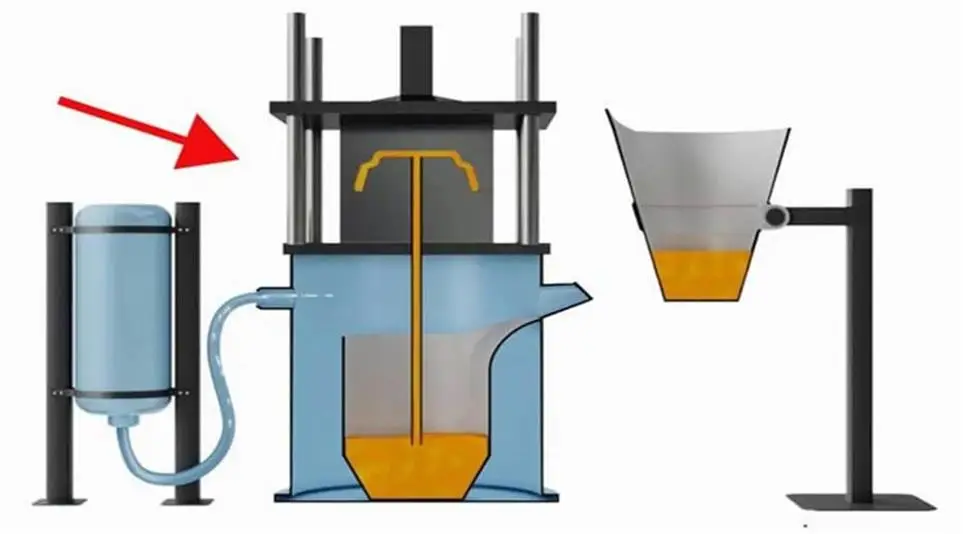

Investment casting, also known as precision casting or lost wax casting, is an advanced metal molding process. Its basic principle is the use of fusible materials (such as wax or plastic) to make a precise fusible model, and then coated with a number of layers of fire-resistant paint on the surface of the model, after drying, hardening to form a whole shell. Afterwards, the model is heated to melt and flow out, thus creating a cavity in the shell. Finally, the molten metal liquid is poured into the mold shell, and the casting can be obtained after cooling.

(2) Precision and Complexity Requirements of Medical Device Casting

The casting process of medical devices has very high requirements for precision, because even small errors may lead to problems in the clinical application of the product. For example, the blade part of a surgical instrument may affect the accuracy and safety of surgery if the casting precision is insufficient. In addition, medical devices often have complex geometries and subtle structural features, which further increase the difficulty of casting.

Casting manufacturers need to use advanced manufacturing technology (such as investment casting medical device technology) and strict quality control measures to ensure that the accuracy and performance of each product can meet the strict requirements of the medical industry.

2.Advantages of investment casting medical devices

(1) High precision, suitable for complex structural design

Investment casting medical device technology is able to achieve very high dimensional accuracy, which is critical for medical devices that require implants that precisely match the structure of the human body. For example, the manufacture of artificial joints and dental implants requires extremely high precision to ensure comfort and functionality after implantation. Investment casting medical devices enable precise replication of these complex structures.

(2) Wide choice of materials for different medical needs

Investment casting technology can use a variety of metal materials, such as stainless steel, cobalt-chromium alloy, titanium alloy and so on. These materials have excellent biocompatibility and mechanical properties, and are very suitable for the manufacture of medical devices. For example, titanium alloys are widely used in the manufacture of orthopedic implants due to their light weight, high strength and good biocompatibility. Stainless steel, on the other hand, is commonly used in the manufacture of surgical instruments due to its corrosion resistance and ease of processing.

(3) High production flexibility, suitable for customized production

Investment casting technology is suitable for small-lot or single-piece production, which makes it able to meet the growing demand for personalization in the medical device market. For example, the production of customized medical devices is particularly important for patients who require special sizes or shapes. The flexibility of investment casting medical devices allows doctors and manufacturers to quickly produce devices that meet the requirements of a patient’s specific situation.

(4) Good surface finish, reducing subsequent processing

Investment casting technology can produce parts with a very high surface finish, which reduces the need for subsequent processing, reduces production costs and shortens the production cycle. For medical devices, a smooth surface not only reduces the risk of infection, but also improves the aesthetics and service life of the device.

3.Application cases of investment casting medical devices

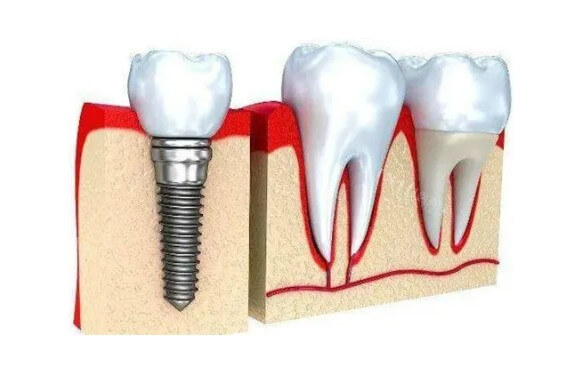

(1) Dental implants

In the dental field, investment casting technology is widely used to manufacture dental implants, such as dental implants. These implants need to have a precise size and shape to ensure a perfect match with the patient’s oral structure. Investment casting medical device technology is able to fulfill this requirement, while also allowing the use of biocompatible materials, such as titanium alloys, to improve the success rate of implants.

(2) Artificial Joints

Artificial joint is another important application field of investment casting technology. Through investment casting medical devices technology, artificial joints with complex geometries and high-quality surfaces can be produced. These joints can accurately simulate the movement of the natural joints of the human body, reduce the pain and discomfort of patients and improve the quality of life.

(3) Precision Surgical Instruments

Investment casting technology is also used to manufacture a variety of precision surgical instruments, such as scalpels, forceps and so on. These instruments need to have high precision and good durability to ensure the safety and effectiveness of surgery. Investment casting medical devices technology can meet these requirements, but also according to the specific needs of doctors for customized production.

(4) Personalized medical devices

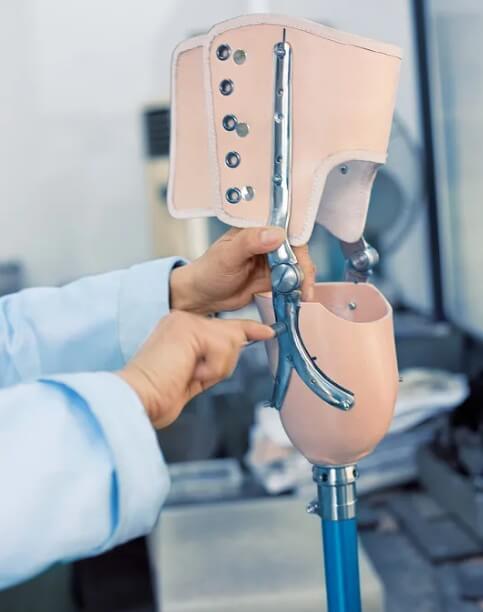

With the progress of medical technology, the demand for personalized medical devices is growing. Investment casting medical device technology according to the patient’s specific situation, rapid production of personalized medical devices to meet the requirements, such as customized prosthetics, orthotics and so on. These devices can better meet the needs of patients, improve the treatment effect and quality of life.

4.Technical challenges and solutions of investment casting medical devices

Investment casting medical devices technology has been widely used because of its ability to create high-precision, complex-shaped parts. However, this process also faces some technical challenges that need to be overcome by specific solutions.

(1) Material selection and property control

Challenges:

Medical devices often require properties such as biocompatibility, corrosion resistance and high strength. Selecting the right materials and ensuring that their performance meets standards is a major challenge.

Solution:

Select proven medical-grade materials, such as titanium alloys, stainless steel and cobalt-chromium alloys, and control material performance through rigorous material testing and heat treatment methods.

(2) Dimensional Accuracy and Surface Quality

Challenge:

Medical devices often require extremely high dimensional accuracy and good surface finish to avoid adverse reactions when used inside the human body.

Solution:

Adopt high-precision wax mold making equipment and advanced casting process, such as vacuum casting, to reduce porosity and surface defects of castings. Meanwhile, the surface quality is further improved by polishing and surface treatment technology.

(3) Control of casting defects

Challenge:

Defects such as shrinkage, cracks and porosity are prone to occur during investment casting, and these defects may affect the safety and effectiveness of medical devices.

Solution:

Optimize casting process parameters such as pouring temperature and speed, use computer simulation to predict possible defects, and perform strict quality control during production.

(4) Production efficiency and cost control

Challenge:

The relatively complex, low productivity and high cost of the investment casting process is a challenge for the mass production of medical devices.

Solution:

Improve production efficiency through automation and intelligent production equipment, and at the same time, reduce production costs by optimizing the production process and using cost-effective materials.

(5) Regulatory Compliance and Quality Control

Challenge:

Medical devices need to comply with strict regulatory requirements, such as ISO 13485 and FDA regulations, to ensure product safety and effectiveness.

Solution:

Establish a comprehensive quality management system, conduct strict quality control at every step from raw material procurement to final product shipment, and conduct regular internal and external audits to ensure product compliance with regulatory requirements.

5.Summary

In the field of personalized medicine and precision medicine, investment casting medical devices will play an increasingly important role. In the future, the application scope of investment casting medical devices will continue to expand, and make greater contributions to improving the level of medical services and human health.