Aluminum die casting: a good choice for modern manufacturing industry

Aluminum die casting technology has promoted the application and development of modern manufacturing industry in many fields through its advantages of precision manufacturing, lightweight design and fast production cycle. This article will comprehensively introduce the relevant knowledge of aluminum and aluminum die casting from many aspects and angles. After understanding all this, it will have a positive impact on your production.

1.What is aluminum die casting

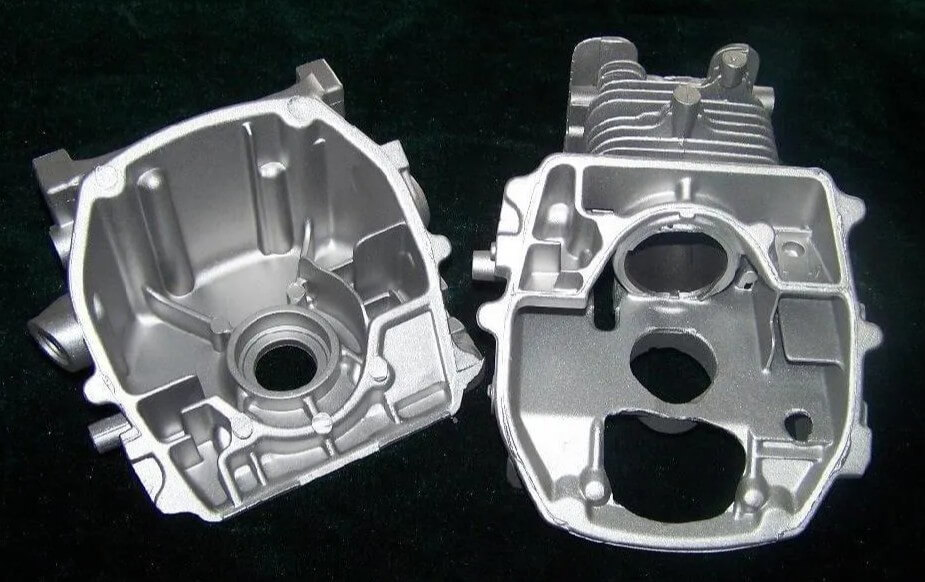

Aluminum die casting is a metal casting process that uses high pressure to inject molten aluminum or aluminum alloy liquid into a mold, and then cools and solidifies under pressure to form aluminum parts or aluminum alloy parts with specific shapes and sizes. The characteristics of this process include high pressure and high speed filling, which enables aluminum die castings to achieve high dimensional accuracy and surface finish.

2.Types of aluminum alloys suitable for die casting

(1) Al-Si alloys:

This type of alloy has good fluidity, filling capacity and thermal cracking resistance, and is suitable for making die castings with complex shapes.

(2) Al-Si-Cu alloys:

This type of alloy adds copper elements to the Al-Si alloy, which improves the strength and hardness of the alloy while maintaining good casting properties.

(3) Al-Mg alloys:

This type of alloy has good corrosion resistance and mechanical properties, but relatively poor casting properties.

(4) ADC12:

This alloy has good fluidity and corrosion resistance and is widely used in various structural parts and body shells.

(5) A384:

This alloy is known for its high strength and good heat resistance and is suitable for the manufacture of automotive parts and mechanical structural parts.

(6) A413:

This aluminum alloy has good mechanical properties and surface quality, but relatively low strength and is suitable for the automotive industry and structural parts manufacturing.

(7) AK5M2:

This type of alloy has high hardness and high strength and is suitable for automotive parts, aircraft and rail transportation.

(8) YL113:

This is a high-strength die-casting aluminum alloy independently developed by China. It has good corrosion resistance, wear resistance and mechanical properties and is widely used in aerospace, automobile engines and other fields.

Summary:

Before performing the aluminum die-casting process, a suitable die-casting aluminum alloy should be selected. The selection of aluminum alloy requires comprehensive consideration of product performance requirements, cost budget, environmental protection and resource utilization. At the same time, the production process needs to be strictly controlled during use to ensure that the product quality meets the standards.

3.Aluminum die casting: alloy characteristics

(1) Lightweight and high strength:

Aluminum alloys have low density but relatively high strength, making them suitable for reducing structural weight while maintaining strength.

(2) Corrosion resistance:

It has good corrosion resistance in the atmosphere and fresh water, and a dense oxide film is easily formed on the surface to protect the interior from corrosion.

(3) Good thermal and electrical conductivity:

It has good thermal and electrical conductivity and is suitable for making heat exchangers and conductive parts.

(4) Easy to process:

It is easy to make parts of different shapes and sizes through various processing methods.

(5) Non-magnetic:

Aluminum alloys are non-magnetic and are suitable for making parts that need to avoid magnetic interference.

(6) Low-temperature toughness:

It can still maintain good toughness in low-temperature environment and is not prone to brittle fracture.

(7) Non-toxicity:

Aluminum alloy is non-toxic and is suitable for making products with high hygiene requirements such as food containers.

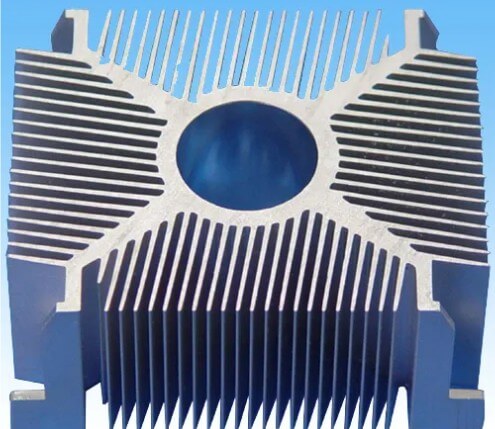

(8) Strong heat dissipation:

It has good heat dissipation performance and is suitable for making thermal management components such as radiators.

(9) Weldability:

Aluminum alloy can be connected by welding, which is convenient for manufacturing complex structures.

(10) Nuclear radiation resistance:

Aluminum alloy has a certain resistance to nuclear radiation and is suitable for the nuclear industry and other fields.

(11) High recycling rate:

Aluminum alloy can be recycled and reused, reducing resource waste and environmental pollution.

4.Advantages of aluminum die casting parts

(1) Beautiful and light:

Aluminum castings have beautiful appearance, light weight, and are easy to transport and install.

(2) High strength and corrosion resistance:

Aluminum castings have low density, but their strength and corrosion resistance are better than cast iron and cast steel.

(3) Good casting performance:

Low melting point, good fluidity, suitable for casting thin-walled and complex structure castings.

(4) High dimensional accuracy:

High dimensional accuracy, good surface finish, and reduced subsequent mechanical processing.

(5) High production efficiency:

High production efficiency, suitable for mass production.

(6) Good economy:

Aluminum castings have a high direct utilization rate, reducing processing equipment and working hours, and have good economic effects.

(7) Wide application:

Aluminum castings are widely used in aerospace, automobile, machinery manufacturing, shipbuilding and modern industry.

5.Is aluminum die casting cheaper than ordinary aluminum? What does their price depend on?

The price comparison between aluminum die casting and ordinary aluminum depends on many factors, including material cost, production cost, product specifications, market demand, product output, etc.

(1) Material cost

Die-cast aluminum usually refers to die-cast aluminum alloy, which contains other alloying elements such as silicon, copper, magnesium, etc. The addition of these elements will improve the performance of aluminum, but may also increase material costs. Ordinary aluminum is purer and has a relatively low material cost.

(2) Production cost:

The production process of die-cast aluminum includes high-pressure and high-speed filling of the cavity, which requires high technology and equipment investment, so the production cost may be high. The production process of ordinary aluminum may be relatively simple and the production cost is low.

(3) Product specifications:

The prices of aluminum products of different specifications are different, and the prices of die-cast aluminum and ordinary aluminum also vary according to specifications. For example, the price of aluminum alloy doors and windows will be affected by factors such as profile wall thickness and cavity design.

(4) Market demand:

Market demand will also affect prices. If the market demand for aluminum die-casting is high, the price may rise. On the contrary, if the demand for ordinary aluminum is large, the price may be relatively low.

(5) Product output:

Die-cast aluminum parts are suitable for mass production. Once the product output increases, the cost is low. Ordinary aluminum has relatively low production efficiency, low output, and relatively high cost.

(6) Economic effect:

Aluminum die casting has high production efficiency and is easy to mechanize and automate. It can improve metal utilization, reduce processing equipment and working hours, and thus reduce production costs to a certain extent.

6.Precautions in the production process of aluminum die casting

Aluminum die casting is an efficient metal forming process, but many aspects need to be paid attention to during the production process to ensure the quality of castings and production efficiency. The following are some key precautions:

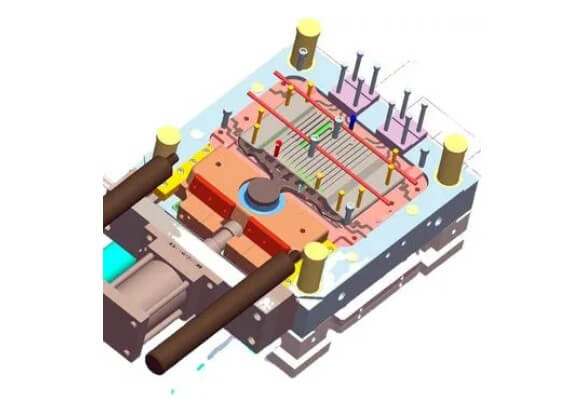

(1) Mold operation:

1) The mold parting surface should be kept clean to avoid burrs and dust accumulation to prevent mold damage.

2) Use the mold cooling system to control the mold temperature, extend the mold life, and improve product quality.

3) Preheat the mold to prevent cracks when the cold mold encounters high-temperature metal liquid.

(2) Alloy composition control:

1) Ensure that the alloy is based on ultra-high purity aluminum and is made of ultra-high purity aluminum, magnesium and copper, etc., and meets strict composition standards.

2) Control the remelting temperature not to exceed 430℃ to reduce the loss of aluminum and magnesium.

(3) Melting process:

1) Pay attention to oxidation, hydrogen absorption, impurities, slagging and iron addition, and take measures to reduce adverse effects.

2) Use appropriate flux for refining, degassing and deslagging, maintain liquid level balance, and control discharge temperature and time.

(4) Die-casting process:

1) Consider demoulding issues and design reasonable demoulding angles and demoulding forces.

2) Control the wall thickness of aluminum alloy die-casting to avoid excessive thickness differences that affect filling.

3) Try to avoid complex mold structures and reduce the use of core pulling and spiral core pulling.

4) For die-castings with special appearance requirements, such as oil injection, consideration should be given in advance.

(5) Cost and quality control:

1) Consider mechanical processing requirements during the design stage to ensure the accuracy of later processing.

2) Optimize mold design and pouring system to reduce scrap rate and control costs.

3) Consider fatigue life and stress distribution to improve the durability of die-castings.

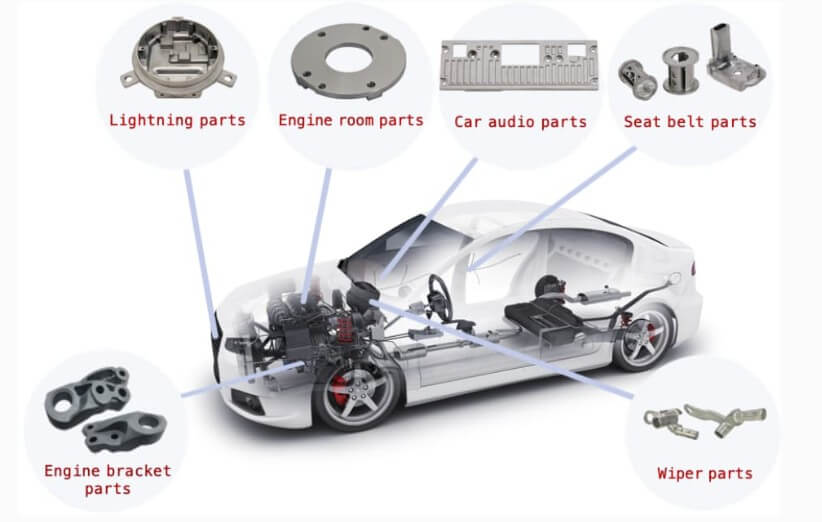

7.Market application areas of aluminum die casting

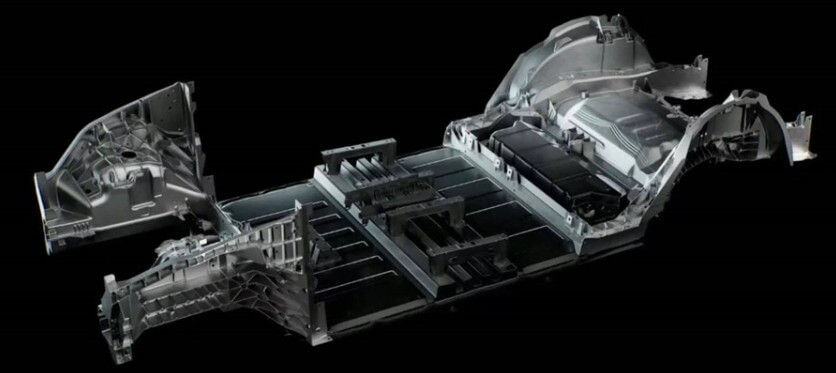

(1) Automobile manufacturing:

Aluminum die castings are widely used in the automotive industry, from engines to body parts, they are everywhere. Including engine parts, transmission systems, suspension systems, chassis parts, exterior decorative parts, etc. The lightweight characteristics and good thermal conductivity of aluminum alloys help reduce vehicle weight and improve fuel efficiency.

(2) Aerospace:

In the process of manufacturing aircraft and spacecraft, aluminum alloy die castings are favored due to their high strength, light weight and good corrosion resistance.

(3) Electronic equipment:

Aluminum alloy die castings are widely used in the field of home appliances and electrical equipment, including air conditioner housings, washing machine drums, refrigerator parts, TV stands, etc., which can improve the texture and appearance of the product.

(4) Industrial machinery and equipment:

Aluminum die casting technology is widely used in industrial machinery and equipment, used to manufacture machine tool parts, pump bodies, valves, pressure vessels, etc., to meet the strength and durability requirements of industrial equipment.

(5) Construction and decoration fields:

Aluminum alloy die-castings are widely used in the construction and decoration fields, including window frames, door and window accessories, interior decoration parts, etc., with the characteristics of light weight, weather resistance and plasticity.

(6) Communication technology:

With the development of the mobile Internet 5G communication industry, the establishment of a large number of communication base stations also requires a large number of aluminum alloy die-casting accessories, especially using its high thermal conductivity to be used in communication equipment radiators.

(7) Furniture and home appliances:

Aluminum alloy die-castings are widely used in furniture and home appliance accessories due to their light weight, rust resistance, waterproofness and low price.

(8) Medical devices:

The precision manufacturing capability of aluminum die-casting technology makes it also used in the field of medical equipment, such as manufacturing precision instruments.

8.Summary

Aluminum die casting technology has been widely used in the fields of automobiles, electronics, aerospace, etc. due to its high efficiency and precision. Understanding the characteristics of aluminum alloys, the advantages of aluminum die castings and the precautions of die-casting aluminum will help us better apply this technology and promote the further development of industrial production.