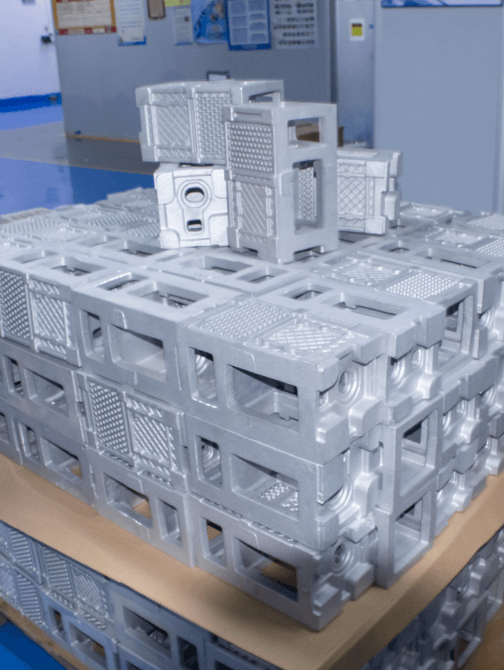

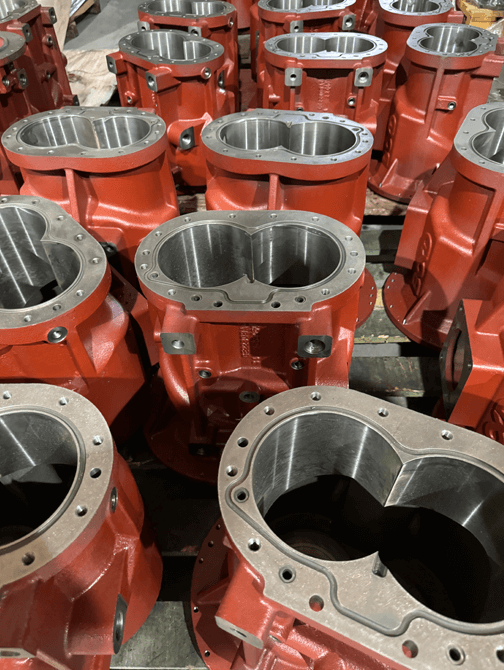

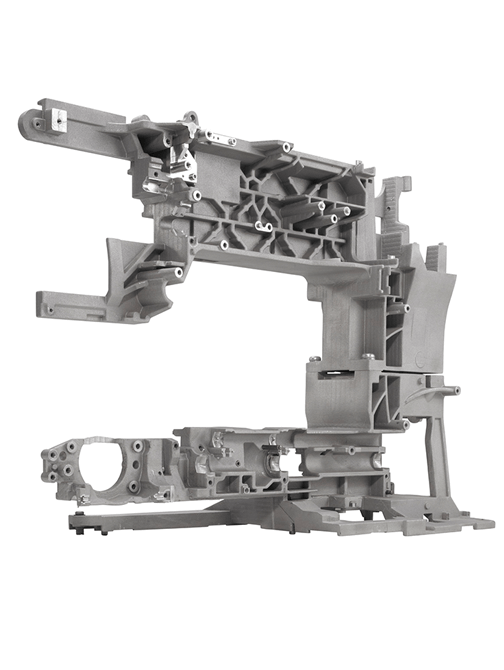

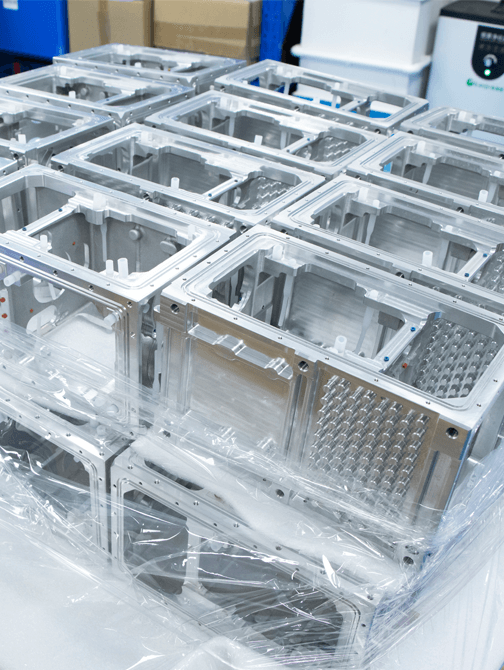

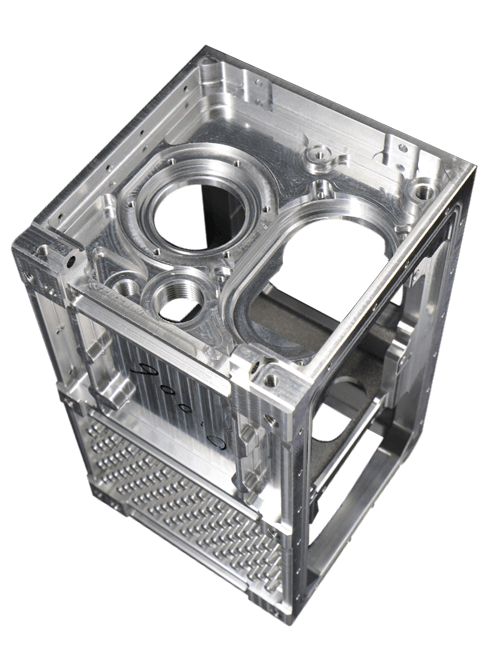

Serving the world with our versatile range of Casting products

Our foundry business is centered around six Electric Arc Furnace (EAF) foundries and numerous value-added coating operations, enabling us to process approximately 13 million tons of castings per year. We are proud to offer the most diverse products to the global optoelectronics, energy, communications and other industries. In addition, we are committed to delivering quality, technology and supply chain solutions that exceed our customers’ expectations, thereby achieving higher value.

In addition, we adopt an environmentally friendly casting model, give priority to the use of electric arc furnace technology to produce high-quality, low-carbon emission castings, and we integrate digital quality control systems. This approach has made Lvxun a leader in the casting industry. Our quality control team’s unremitting efforts in implementing scientific control initiatives will further improve the standards of our future casting parts production.