535 aluminum casting typical uses: comprehensive analysis of application areas

535 aluminum casting typical uses include the automotive industry, aerospace industry, electronic and electrical industry, mechanical equipment manufacturing, architectural decoration, medical equipment, sports equipment and other fields. These applications demonstrate the wide range of uses and important role of 535 aluminum castings in various fields. . This article will focus on the 535 aluminum casting typical uses. First, we will analyze the main characteristics of 518 aluminum alloy and the manufacturing process of 518 aluminum castings to give everyone a basic understanding. Next, we will discuss the central topic of the article, which is the main 535 aluminum casting typical uses, and finally give typical cases to support it.

1.Basic characteristics of 1.535 aluminum alloy

535 aluminum alloy belongs to the Al-Mg series alloy. The main alloy element is magnesium, with a content between 4.5% and 5.5%. This alloy has the following basic properties:

(1) Moderate intensity:

The strength of 535 aluminum alloy is slightly higher than that of pure aluminum, but lower than other high-strength aluminum alloys. It is suitable for occasions with moderate strength requirements.

(2) Good corrosion resistance:

The addition of magnesium significantly improves the corrosion resistance of aluminum alloys, allowing it to perform well in harsh environments.

(3) Excellent liquidity:

535 aluminum alloy shows good fluidity during the casting process, can fill complex mold cavities, and is suitable for producing castings with complex shapes.

(4) Good weldability:

The alloy can be joined by various welding methods to facilitate subsequent processing and assembly.

(5)Aesthetics:

The surface of 535 aluminum alloy can be subjected to various treatments, such as anodizing, sandblasting, etc., to give it a good decorative effect.

2.535 aluminum casting manufacturing process introduction

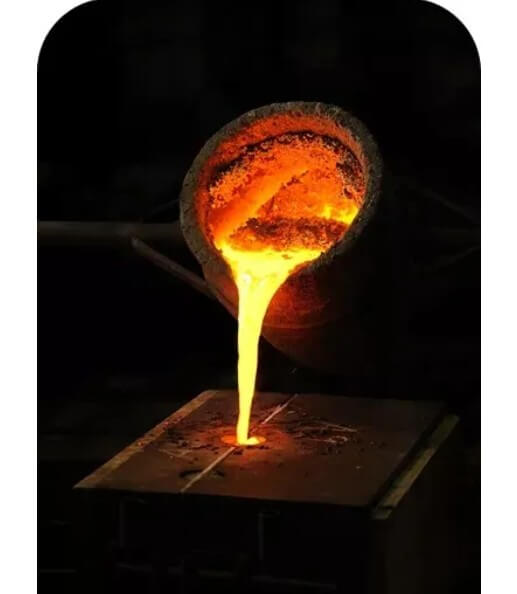

(1) Casting process:

535 aluminum castings are usually manufactured using metal gravity casting or low pressure casting processes. Metal gravity casting uses gravity to inject molten aluminum into a metal mold to form a casting. The process is simple to operate, low in cost, and suitable for mass production. Low-pressure casting is to hydraulically pour aluminum into the mold under low-pressure conditions, which can obtain a denser structure and higher dimensional accuracy.

(2) Subsequent processing technology:

After casting is completed, 535 aluminum castings usually require heat treatment and surface treatment. Heat treatment mainly includes solution treatment and aging treatment. Through the heating and cooling process, the mechanical properties of aluminum castings are optimized. Surface treatment includes anodizing, electroplating and other processes to improve the corrosion resistance and aesthetics of aluminum castings.

3.535 aluminum casting typical uses

(1) 535 aluminum casting typical uses 1: Application in the automotive industry

The automotive industry is one of the important application areas of 535 aluminum alloy. As the trend of automobile lightweighting continues to advance, aluminum alloy castings are increasingly used in automobile parts. In the automotive industry, 535 aluminum casting typical uses include but are not limited to the following:

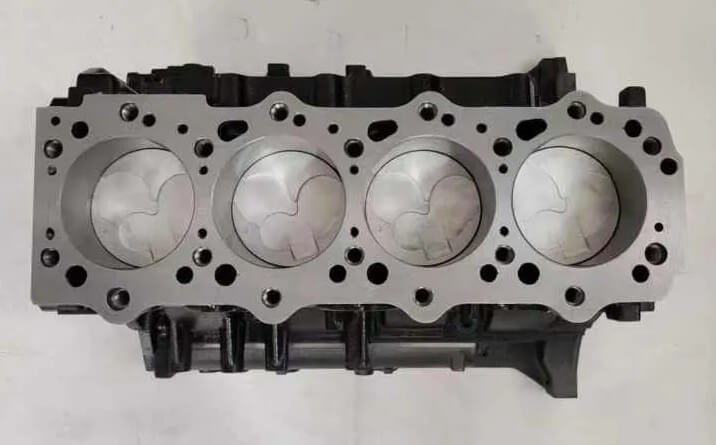

1) Engine block and cylinder head:

535 aluminum alloy has good thermal conductivity and corrosion resistance, and is suitable for manufacturing engine blocks and cylinder heads. Compared with traditional cast iron materials, aluminum alloy castings can significantly reduce the mass of the engine and improve fuel economy.

2) Wheels:

The strength and toughness of 535 aluminum alloy make it an ideal material for manufacturing automobile wheels. Aluminum alloy wheels are not only light in weight, but also have good dynamic balance performance and aesthetics, which can improve the car’s handling and comfort.

3) Suspension system components:

535 aluminum alloy can be used to manufacture control arms, steering knuckles and other components in suspension systems. These components bear heavy loads while the car is driving. The high strength and good fatigue resistance of aluminum alloy castings can ensure their reliability and safety.

4) Body structural parts:

Some high-end car body structural parts have also begun to use 535 aluminum alloy castings, such as door frames, front and rear bumpers, etc. Aluminum alloy castings can improve the rigidity and safety of the body while reducing the weight of the entire vehicle.

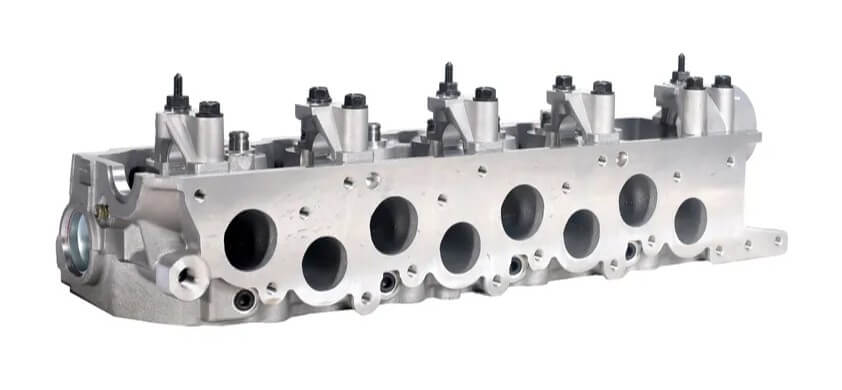

(2) 535 aluminum casting typical uses 2: Application in the aerospace industry

The aerospace industry has extremely high requirements on material performance, and 535 aluminum alloy has also been widely used in this field because of its good comprehensive properties. In the aerospace industry, 535 aluminum casting typical uses include:

1) Aircraft structural parts:

535 aluminum alloy can be used to manufacture aircraft skins, frames, ribs and other structural parts. These components bear large aerodynamic loads and vibration loads during aircraft flight. The high strength and good fatigue resistance of aluminum alloy castings can ensure their reliability and safety.

2) Engine parts:

535 aluminum alloy has good heat resistance and corrosion resistance and is suitable for manufacturing certain parts of aeroengines, such as fan blades, compressor blades, etc. These components work under conditions of high temperature, high pressure, and high speed, and aluminum alloy castings can meet their demanding performance requirements.

3) Spacecraft structural parts:

535 aluminum alloy can be used to manufacture structural parts such as spacecraft cabins and brackets. These components bear heavy mechanical and environmental loads during spacecraft launch and operation. The high strength and good corrosion resistance of aluminum alloy castings can ensure their reliability and long life.

(3) 535 aluminum casting typical uses 3: Application in the electronic and electrical industry

With the continuous development of electronic and electrical products, the requirements for housing materials and structural parts are becoming higher and higher. 535 aluminum alloy has been widely used in this field because of its good properties. Typical uses include:

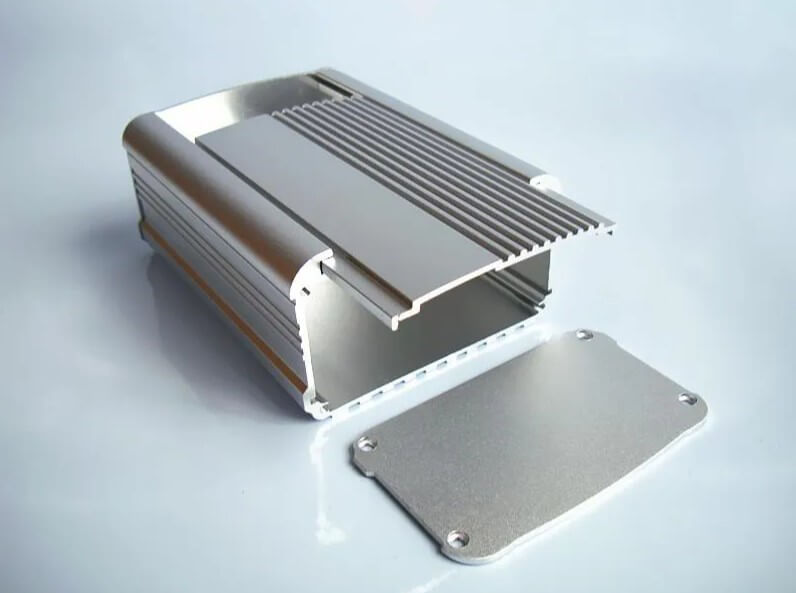

1) Laptop case:

535 aluminum alloy has good strength and aesthetics and is suitable for manufacturing laptop casings. The aluminum alloy shell is not only lightweight, but also has good pressure resistance and heat dissipation properties, which can improve the durability and use experience of the laptop.

2) Mobile phone middle frame:

535 aluminum alloy can be used to manufacture the middle frame of mobile phones, providing good strength and rigidity to protect the internal components of mobile phones from damage. At the same time, the aluminum alloy middle frame can achieve beautiful effects through various surface treatment processes and improve the class of the mobile phone.

3) Electrical housing:

535 aluminum alloy can be used to manufacture the casings of various electrical appliances, such as televisions, air conditioners, washing machines, etc. The aluminum alloy shell is not only light in weight, but also has good corrosion resistance and aesthetics, which can improve the quality and market competitiveness of electrical appliances.

(4) Typical uses 4 of 535 aluminum castings: Application in mechanical equipment manufacturing

1) Pump body and valve:

535 aluminum alloy has good corrosion resistance and high mechanical strength, and is very suitable for manufacturing mechanical equipment components such as pump bodies and valves. The excellent processing performance of aluminum castings also enables the pump body and valves to be manufactured with higher precision and longer service life.

2) Industrial robot components:

In industrial robots, 535 aluminum casting typical uses are mainly concentrated in robot arms, joints and other components. The lightweight and high-strength properties of 535 aluminum alloy enable industrial robots to have higher movement speed and accuracy, while reducing energy consumption and maintenance costs.

(5) 535 aluminum casting typical uses 5: Application in the field of architectural decoration

1) Door and window frames:

The application of aluminum castings in building door and window frames has the advantages of light weight, high strength, and good sealing. The good corrosion resistance and aesthetics of 535 aluminum alloy make the aluminum cast door and window frames not only have a long service life, but also achieve different decorative effects through various surface treatment processes.

2) Curtain wall panels:

The application of aluminum castings in building curtain wall panels mainly benefits from its light weight, high strength and good weather resistance. The excellent processing performance of 535 aluminum alloy also enables curtain wall panels to achieve more design styles and meet the diverse needs of modern buildings.

(6) 535 aluminum casting typical uses 6: Applications in other fields

1) Medical devices:

The good corrosion resistance and biocompatibility of 535 aluminum alloy make it have broad application prospects in medical device manufacturing, such as surgical instruments, orthopedic fixators, etc.

2) Sports equipment:

In sports equipment, 535 aluminum casting typical uses include bicycle frames, golf clubs, etc., mainly due to its light weight, high strength and good fatigue resistance.

4.Specific case analysis of 535 aluminum casting typical uses

(1) Application examples in the automotive industry

In high-end BMW models, 535 aluminum castings are typically used to manufacture engine blocks and transmission system components. By using aluminum castings, the model’s overall weight is significantly reduced, fuel efficiency is improved by 15%, and emissions are also significantly reduced. This not only improves the vehicle’s performance and environmental performance, but also enhances market competitiveness.

(2) Application examples in aerospace field

Boeing uses 535 aluminum castings to make the fuselage frame and landing gear in its new aircraft. These aluminum castings not only reduce the weight of the aircraft, but also increase the aircraft’s structural strength and corrosion resistance, ensuring flight safety and performance.

(3) Use cases in construction and electronic products

In a modern office building, 535 aluminum castings are widely used to make window frames and door handles. These aluminum castings are not only beautiful and durable, but also have good corrosion resistance and can maintain stable performance in various climate conditions. In addition, many well-known brands of high-end laptops also use aluminum castings to make their casings, which not only improves the aesthetics and structural strength of the product, but also effectively improves heat dissipation performance and ensures the stable operation of the equipment.

5.Summary

The above cases demonstrate the breadth and diversity of typical uses of 535 aluminum castings. Its excellent performance and diverse processing characteristics provide reliable solutions for product manufacturing in various industries.

What do you think?

Hey superb blog! Does running a blog similar to this take

a lot of work? I’ve no knowledge of programming however I had been hoping to start my own blog in the near future.

Anyways, should you have any ideas or tips for

new blog owners please share. I understand this is

off topic however I simply had to ask. Appreciate it!

This is my first time pay a quick visit at here and i am actually impressed to read all at single place.

I don’t even know how I ended up right here, but

I believed this submit was great. I don’t realize

who you are however certainly you are going to a famous blogger in the

event you aren’t already. Cheers!

Hello, i think that i saw you visited my website thus i came

to return the desire?.I am attempting to in finding things to enhance my website!I suppose

its good enough to use a few of your ideas!!

Hello it’s me, I am also visiting this web site daily, this site is in fact fastidious and the

viewers are in fact sharing fastidious thoughts.

As the admin of this website is working, no doubt very rapidly it will be famous, due to its feature contents.

This post gives clear idea in support of the new visitors of blogging, that genuinely how to do running a

blog.

Hurrah, that’s what I was seeking for, what a information! present here at this webpage, thanks admin of this web page.

Stunning story there. What occurred after? Thanks!

I am not certain where you are getting your info, but good

topic. I must spend some time studying more or understanding more.

Thanks for magnificent information I was on the lookout for this info for

my mission.

That is really interesting, You’re an excessively skilled blogger.

I’ve joined your feed and look ahead to in quest of more of your fantastic post.

Also, I have shared your web site in my social networks

I just like the valuable information you supply on your articles.

I will bookmark your blog and take a look at once

more right here regularly. I am relatively sure I will be informed lots of new stuff

right right here! Good luck for the next!

My spouse and I absolutely love your blog and find a lot of

your post’s to be precisely what I’m looking for. Does one offer

guest writers to write content in your case? I wouldn’t mind publishing a post or

elaborating on some of the subjects you write regarding here.

Again, awesome site!

I want to to thank you for this great read!!

I absolutely enjoyed every little bit of it. I have got you bookmarked to check out new stuff you post…

I was curious if you ever considered changing the layout of

your blog? Its very well written; I love what youve got to say.

But maybe you could a little more in the way of content so people could connect with it better.

Youve got an awful lot of text for only having 1 or 2 images.

Maybe you could space it out better?

Great site you have here but I was wanting to know if you knew of

any message boards that cover the same topics discussed in this article?

I’d really love to be a part of group where I can get comments from other knowledgeable individuals that share the same interest.

If you have any suggestions, please let me know. Thanks!

Hello, just wanted to mention, I enjoyed this blog post.

It was funny. Keep on posting!

I’m impressed, I must say. Rarely do I come across a blog that’s

both equally educative and amusing, and without a doubt, you’ve hit the nail

on the head. The issue is an issue that not enough folks are speaking intelligently about.

I’m very happy I found this in my search for something concerning this.