518 aluminum casting typical uses: comprehensive analysis of application fields

In today’s manufacturing industry, the 518 aluminum casting typical uses are constantly expanding. Its lightweight characteristics and recyclability not only meet the needs of product performance, but also comply with environmental protection trends, making 518 aluminum castings very popular in the market. This article will focus on the 518 aluminum casting typical uses. First, we will analyze the main characteristics of 518 aluminum alloy and the technical advantages of 518 aluminum castings to give everyone a basic understanding. Next, we will discuss the central topic of the article, which is the main 518 aluminum casting typical uses, and finally give typical cases to support it.

1.Main characteristics of 1.518 aluminum alloy

(1) Chemical composition

518 aluminum alloy mainly contains aluminum, magnesium, silicon and other elements, of which aluminum is the basic element. The addition of magnesium and silicon significantly improves the mechanical properties and corrosion resistance of the alloy. The chemistry of this alloy is designed to provide excellent strength and hardness while remaining lightweight.

(2) Mechanical properties

518 aluminum alloy has high tensile strength and yield strength and is suitable for applications with high stress and load. In addition, its hardness also makes the alloy excellent in wear resistance, effectively resisting the wear and tear of daily use.

(3) Processing performance

518 aluminum alloy has good casting and cutting properties and is suitable for various complex processing needs. Its weldability is also good, which facilitates structural connection through welding processes, enhancing its application potential in manufacturing large or complex structural parts.

(4) Corrosion resistance

The alloy shows good corrosion resistance in a variety of environments, especially in marine atmosphere and industrial atmosphere. It can effectively resist the corrosion of salt spray and industrial gas, extending the service life of the product.

(5) Lightweight advantage

The density of 518 aluminum alloy is much lower than that of steel, which allows its application in fields such as automobiles and aerospace to significantly reduce structural weight, thereby reducing fuel consumption and operating costs, and improving fuel efficiency and operating performance.

2.Technical advantages of 518 aluminum castings

(1) Heat treatment strengthening

The mechanical properties of 518 aluminum alloy can be significantly improved through T6 heat treatment, including tensile strength and yield strength. This heat treatment process involves solution treatment and artificial aging to fully precipitate the strengthening phase in the alloy, thereby enhancing its hardness and strength.

(2) Surface treatment technology

In order to further improve the corrosion resistance and aesthetics of 518 aluminum alloy, surface treatment technologies such as anodizing and electroplating can be used. Anodizing can form a hard oxide film on the aluminum surface to effectively prevent corrosion and wear; while electroplating can provide an additional protective layer and increase the decorativeness of the surface.

(3) Strong designability

518 aluminum alloy castings have good designability, and their properties can be adjusted by changing the alloy composition and processing technology to adapt to different application requirements. This flexibility allows 518 aluminum alloy to find a wide range of applications in multiple industries.

(4) Cost-benefit analysis

Although the initial production cost of 518 aluminum alloy may be higher than some traditional materials, its superior durability and lightweight properties reduce long-term maintenance and operating costs. Taken together, 518 aluminum alloy provides good cost-effectiveness, especially in demanding industrial applications.

3.518 aluminum casting typical uses

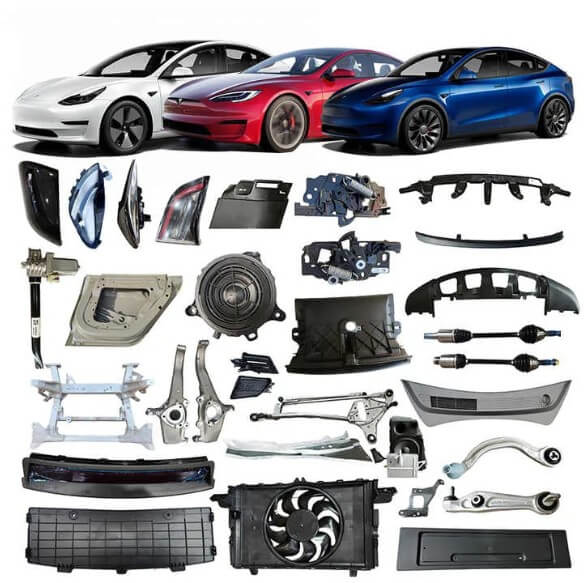

(1) 518 aluminum casting typical uses 1: Application in the automotive industry

The automotive industry is one of the important application areas of 518 aluminum castings. As the trend of automobile lightweighting continues to strengthen, aluminum castings are increasingly used in automobile parts. 518 aluminum casting typical uses include manufacturing key components such as automobile engine blocks, cylinder heads, transmission housings, steering knuckles, and control arms.

1) Engine block and cylinder head:

The engine is the core component of the car, and its performance directly affects the car’s power and fuel economy. Engine cylinder blocks and cylinder heads made of 518 aluminum castings have the advantages of light weight, good thermal conductivity, and corrosion resistance, which can significantly improve the efficiency and reliability of the engine.

2) Transmission housing:

The transmission is an important part of the car’s transmission system, and its performance directly affects the car’s driving experience. The transmission housing made of 518 aluminum castings has the advantages of light weight and high strength, which can improve the transmission efficiency and reliability of the transmission.

3) Steering knuckle and control arm:

Steering knuckles and control arms are important components of the car’s suspension system, and their performance directly affects the car’s handling and comfort. Steering knuckles and control arms made of 518 aluminum castings have the advantages of light weight, high strength, and corrosion resistance, which can improve the stability and reliability of the vehicle suspension system.

(2) 518 aluminum casting typical uses 2: Application in aerospace industry

The aerospace industry has extremely high requirements for materials. It not only requires materials to have properties such as light weight, high strength, and high stiffness, but also requires materials to have excellent corrosion resistance and fatigue resistance. 518 aluminum castings are widely used in the aerospace industry due to their excellent properties.

1) Aircraft structural parts:

In the aviation field, 518 aluminum casting typical uses are mainly in the manufacture of aircraft landing gear, engine brackets, door frames and other structural parts. These parts require materials with high strength, high stiffness, and good corrosion resistance. 518 aluminum castings can meet these requirements.

2) Rocket and satellite components:

518 aluminum castings can also be used to manufacture certain parts of rockets and satellites, such as fuel tank brackets, structural frames, etc. These parts require materials with lightweight, high strength, high temperature resistance and other properties. 518 aluminum castings can also meet these demanding requirements.

(3) 518 aluminum casting typical uses 3: Application in the electronic and electrical industry

With the continuous development of electronic and electrical products, the requirements for housing materials are becoming higher and higher. 518 aluminum castings are widely used in the electronic and electrical industry due to their good mechanical properties, corrosion resistance and processability.

1) Computer and mobile phone cases:

518 aluminum castings can be used to make metal casings for computers and mobile phones. They have the advantages of beauty, durability, and good heat dissipation performance. Aluminum casting casings are stronger and more durable than plastic casings and better protect internal components.

2) Electrical accessories:

518 aluminum castings can also be used to manufacture various electrical accessories, such as power supply casings, radiators, etc. These parts require materials with good heat dissipation properties and mechanical strength, and 518 aluminum castings can meet these requirements.

(4) 518 aluminum casting typical uses 4: Application in the construction industry

The construction industry is another important application area where 518 aluminum castings are typically used. Aluminum castings are widely used in the construction field due to their good corrosion resistance and decorative properties.

1) Door and window frames:

518 aluminum castings can be used to manufacture door and window frames, which have the advantages of light weight, high strength, and good sealing performance. Compared with traditional steel windows and wooden windows, aluminum casting doors and windows are more durable and beautiful, and are not easily deformed.

2) Decorative materials:

518 aluminum castings can also be used to manufacture various building decoration materials, such as aluminum plates, aluminum grilles, etc. These materials have the advantages of beauty, durability, fire resistance, etc., and are widely used in high-end construction and interior decoration.

(5) 518 aluminum casting typical uses 5: Applications in other fields

In addition to the above fields, 518 aluminum casting typical uses also include other application fields, such as medical equipment, sports equipment, furniture, etc.

1) Medical devices:

518 aluminum castings can be used to manufacture certain parts of medical equipment, such as operating table frames, wheelchair brackets, etc. These parts require materials with high strength and good corrosion resistance. 518 aluminum castings can meet these requirements.

2) Sports equipment:

518 aluminum castings can be used to manufacture certain parts of sports equipment, such as bicycle frames, ski bindings, etc. These parts require materials with lightweight, high strength, high stiffness and other properties, and 518 aluminum castings can also meet these requirements.

3) Furniture:

518 aluminum castings can also be used to manufacture certain parts of furniture, such as table and chair legs, cabinet door frames, etc. These parts require materials with beautiful appearance, durability, and high mechanical strength. 518 aluminum castings can meet these requirements.

summary:

In short, 518 aluminum castings are typically used in a wide range of fields and industries. With the continuous advancement of science and technology and the development of industry, it is believed that the 518 aluminum casting typical uses will be further expanded and contribute to the development of various industries.

4.Specific case analysis of 518 aluminum casting typical uses

(1) Automobile lightweight cases

In new energy vehicles, 518 aluminum castings are typically used to reduce the weight of the vehicle body, thereby improving cruising range and energy efficiency. For example, electric vehicle manufacturers such as Tesla make extensive use of aluminum alloy castings to optimize vehicle performance and extend battery life.

(2) Improvement of aviation efficiency

In aircraft manufacturing, the 518 aluminum casting typical uses is to reduce the structural weight of the aircraft, thereby improving flight efficiency and fuel economy. Aircraft manufacturers such as Boeing and Airbus use aluminum alloy materials in many of their aircraft to enhance the performance and competitiveness of the aircraft.

(3) Heat dissipation of electronic products

In high-performance electronic equipment such as servers and high-end laptops, 518 aluminum alloy is used as heat sinks and casings due to its excellent heat dissipation properties. These applications effectively help equipment maintain appropriate temperatures during high-performance operation, thereby ensuring equipment stability and reliability.

5.Summary

518 aluminum casting typical uses range from the automotive industry to aerospace, from electronic products to building materials, as well as medical equipment, sports equipment, furniture and other fields. 518 aluminum alloy has demonstrated its unique value and potential. With the advancement of technology and changes in market demand, the application fields of 518 aluminum castings will continue to expand, and their technical performance will also continue to improve.

What do you think?

[…] and is suitable for manufacturing parts with complex shapes. However, the smelting process of cast aluminum is prone to produce oxide inclusions, which affects the quality of the casting, and the cost of […]

[…] processing industry. It has various types, exquisite production technology and a wide range of applications. This article will provide you with an encyclopedia of aluminum billet knowledge, from […]