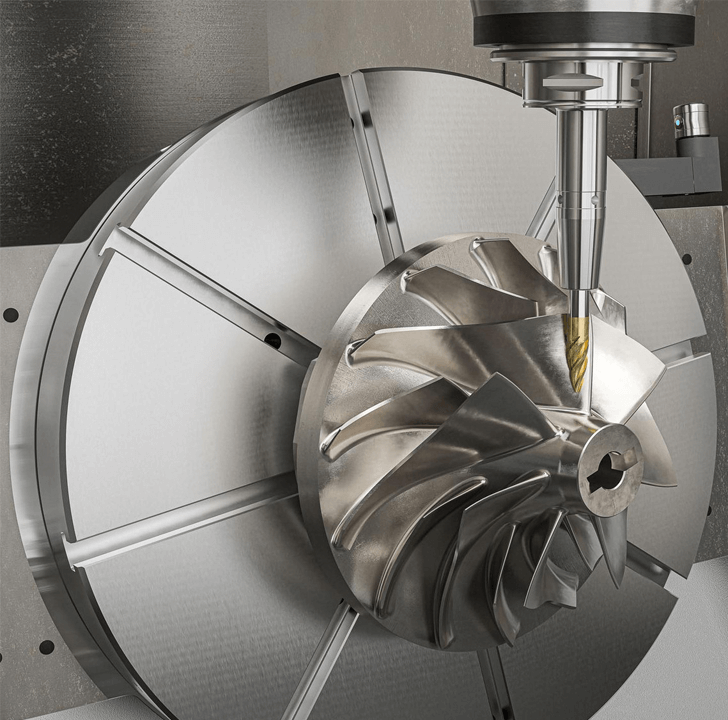

- Ultra-Precise 5-Axis Machining Parts

5-axis milling is suitable for turbo blowers, turbochargers, valve bodies, blades, aviation structural parts, complex medical parts, strict X-detection internal quality inspection, small batch processing of raw materials, long-term demand and mass production provide cost Optimize plan.

5 Axis Machining

5-axis CNC machining involves simultaneous movement along five axes—three linear (X, Y, Z) and two rotational. This capability allows for the creation of complex parts in a single setup, significantly enhancing precision and efficiency. By moving the cutting tool and workpiece along these five different axes, the 5-axis CNC can produce highly intricate shapes and detailed features.

Control focus:

Invar is a difficult-to-machine material. The nickel content of >30% has high toughness. The material is relatively soft and has low thermal conductivity. The tool is prone to high temperature, the surface is easy to harden and deform, the processing efficiency is low, and the tool cost is high. For different impeller structures, the optimal rough processing solution is selected to control the working hours. Super wear-resistant coated tools and low-temperature cutting lubricants are used to control cutting heat, avoid the influence of processing deformation, and complete all geometric contours and important dimensions.

Invar turbine materials are expensive, involving electron beam welding of shafts and turbines of different materials, welding flaw detection, elimination of internal stress and grinding. We have rich experience.

For trial production and small batch production, rods are selected, and they are completed by CNC turning blanks and 5-axis milling. If it is a long-term demand, it is recommended to cast blanks to optimize the costs of materials/rough processing/tools. This process is suitable for the production of stainless steel and titanium alloy impellers and multi-layer blade disks.

- We have high standards for 5-axis milling

We manufacture your custom parts according to strict manufacturing standards and ensure all parts and processes adhere to the LVXUN Standard. A thorough verification of these requirements is included in our inspection report that we ship with every order.

01

LVXUN 5-axis machining has many manufacturing cases of high-demand projects, providing complete FMEA, PFMEA and 5-axis milling 3D simulation from material performance verification, 5-axis milling, overall quenching, internal gravity elimination, transfer, electron beam welding, grinding, dynamic balancing G1, 3D digital analog comparison, full-size measurement, 10-year quality traceability, etc., to ensure the stability and feasibility of the process and avoid delayed delivery.

02

5-axis machining is suitable for early design verification and one-time machining and forming of complex parts with high requirements. 5-axis milling can cut part geometries and complex shapes, which is not possible with other machining processes, because the excellent mobility of the two rotating axes and the workpiece to the tool rotating axis can be used for 5-face processing.

03

5-axis milling does not require complex fixtures, and there is no fixture interference factor. The milling spindle head can run close to the workpiece position, effectively shortening the cutting tool length, reducing vibration and deflection, increasing cutting speed, more compact tool movement, and improving surface finishing capabilities.