- Founded in 2015

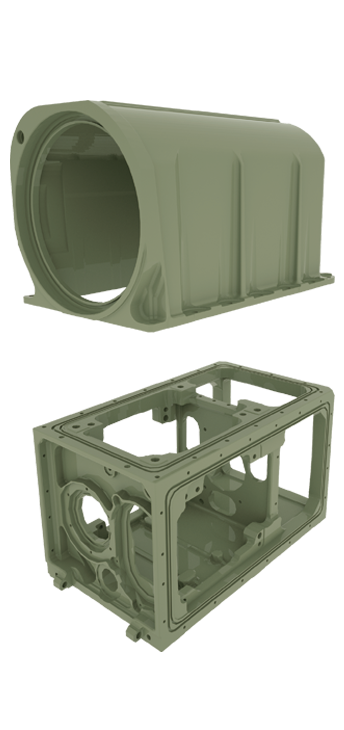

We are shaping the future of parts

Sustainable and visionary casting solutions that serve customers, communities, people and the planet.

100%

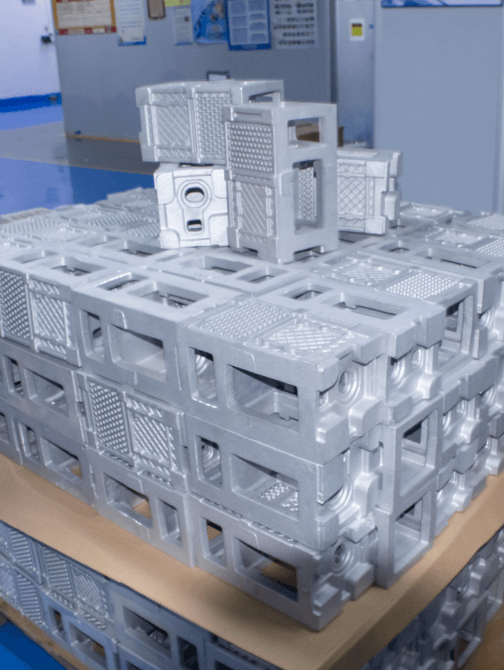

Our products are 100% inspected and include full size inspection reports.

98%

The skilled level of mass production reaches 98%.

- Become a customer

A greener casting provider

As we move forward, we are committed to transparently sharing our sustainability efforts, milestones and achievements. In this way, we aim to inspire and educate others in the industry and contribute to a more sustainable and responsible foundry industry as a whole.

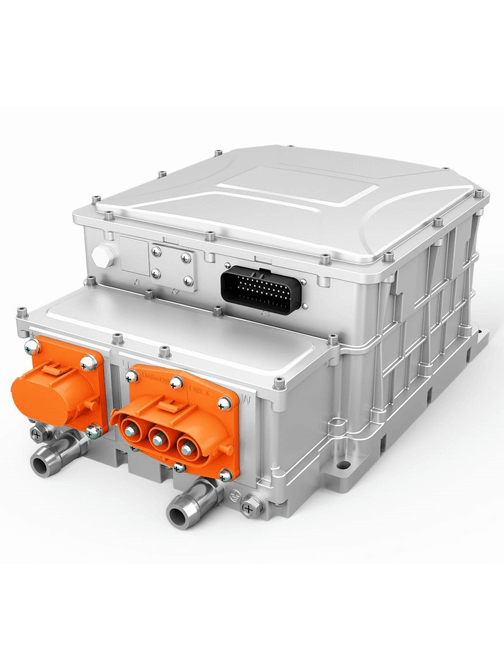

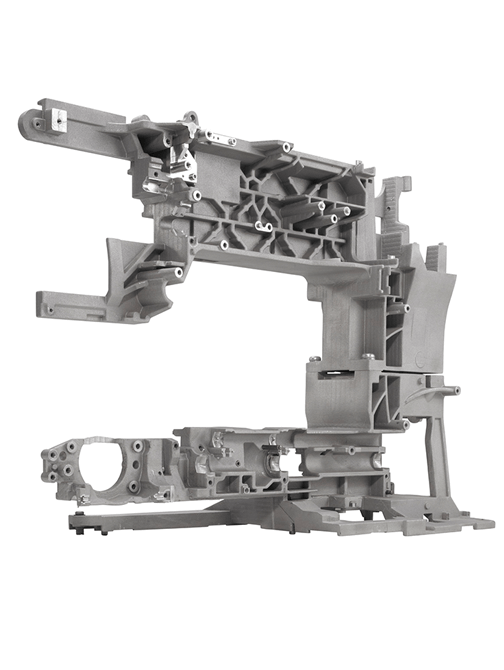

- Solutions & Products

- Eco Innovation

Customer empowerment in a future-focused world

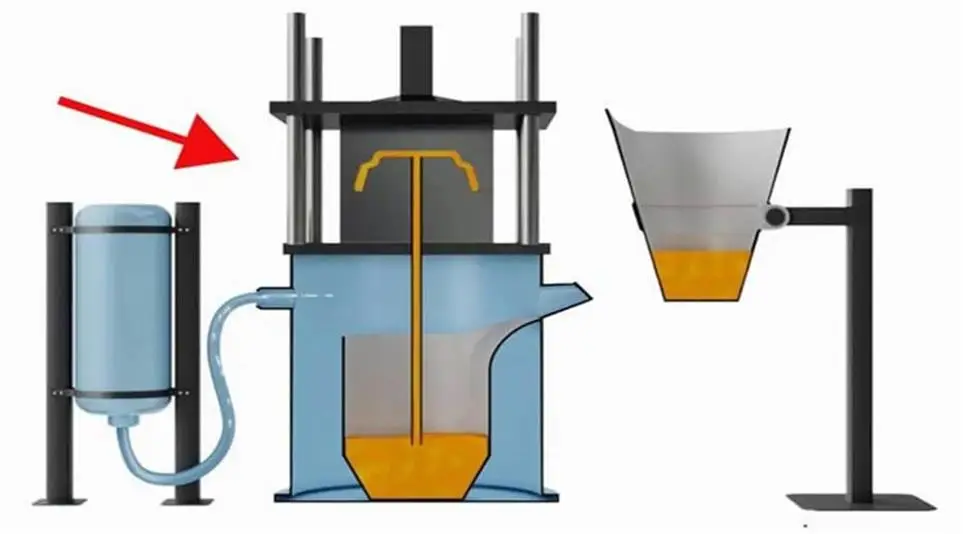

Enhance your applications with Lvxun Process Technology Division. Our team of experts provides cutting-edge solutions, computational modeling and technical support to deliver a sustainable future for all business sectors. Join us and drive excellence and innovation together.

In Lvxun’s Product Technology Department, our engineers and professionals utilize a variety of advanced and sophisticated resources. From cutting-edge testing to mold flow analysis and failure analysis, we pave the way for the next generation of casting in nearly every application. In our state-of-the-art laboratories and facilities, the future is taking shape.

- Products

Sustainable casting for a better future

- Quality Control

Quality Control of Lvxun Castings

Lvxun’s product technology department provides engineers and professionals with a wide range of cutting-edge resources, including advanced testing, metallographic analysis, mold flow analysis, metal fatigue testing, salt spray testing, comprehensive failure analysis and risk control, etc.

- R&D